Method and apparatus for modeling injection of a fluid in a mold cavity

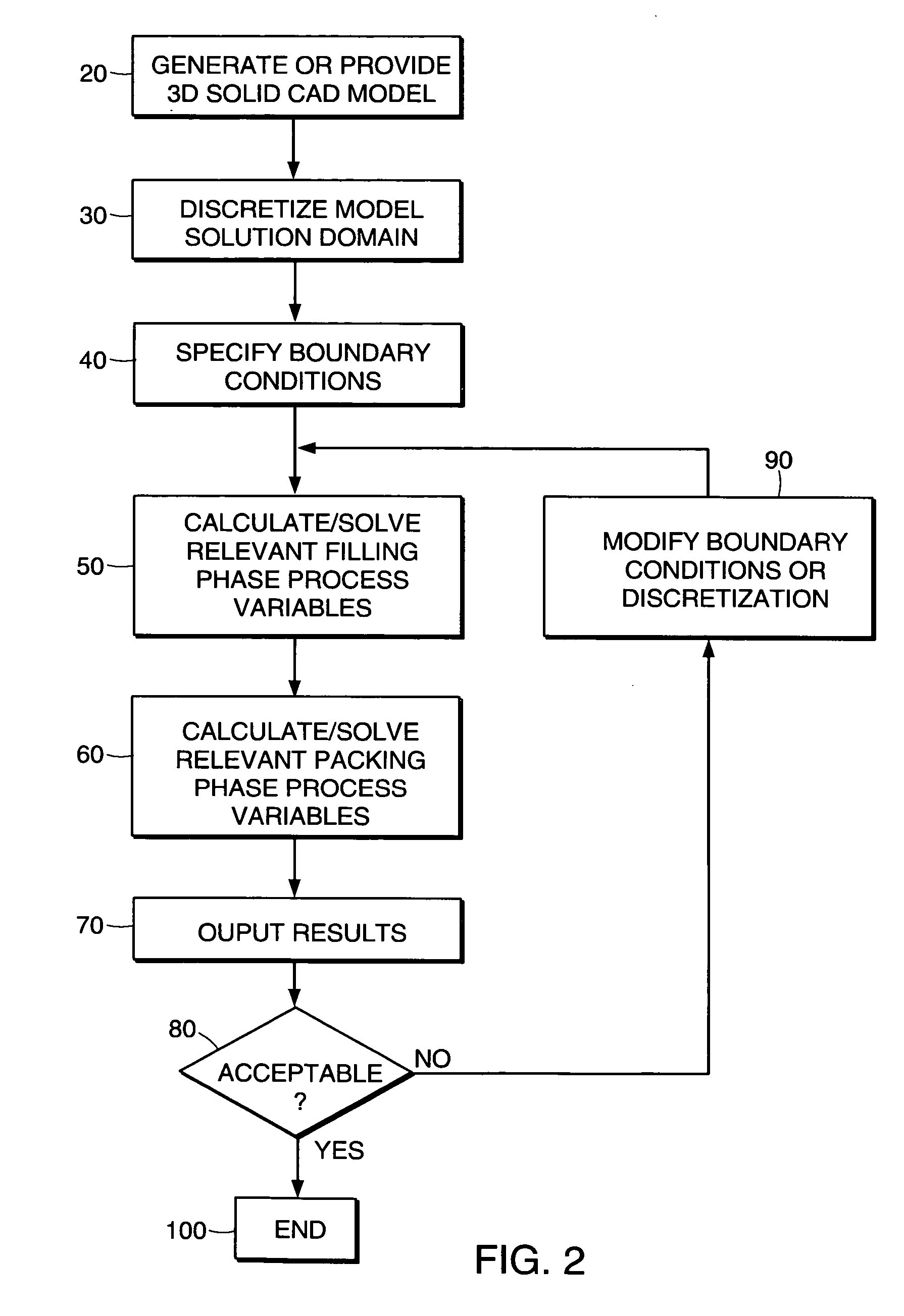

a technology of injection molding and fluid flow, applied in the field of three-dimensional modeling of fluid flow in the cavity, can solve the problem that the accurate simulation of injection molding requires a typically non-isothermal analysis of the molten polymer, and achieve the effect of increasing the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Modeling of the injection molding process in a three dimensional simulation can be described by the conservation equations for mass, momentum, and energy, respectively, as follows: ∂ρ∂t+∇·(ρ v→)=0(3)

where ρ is density, v is velocity, t is time, ∇ stands for the gradient with respect to a position vector, and → denotes a vector quantity. ρ(∂v→∂t+v→·∇v→)+∇·P=ρ g→(4)

where P is the momentum flux and g is the gravity force. ρ(∂U^∂t+v->·∇U^)+P:D+∇·q->=ρ Q(5)

where U is specific internal energy, D is the deformation rate tensor, q is heat flux, and Q is the specific heat rate which signifies other heat sources or sinks.

[0063] Equation 4 is commonly expressed in terms of temperature and pressure, and for the case in which Q=0, i.e. no additional heat sources or sinks, typical for thermoplastics, takes the form, ρ Cp(∂T∂t+v->·∇T)+Tρ∂ρ∂T(∂p∂t+v->·∇p)=η γ.2+∇·(κ∇T)(6)

where Cp is specific heat, T is temperature, p is pressure, η is viscosity, is shear rate, and κ is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com