Mixed gas insulating medium containing environmentally friendly gaseous trifluoroiodomethane and preparation method of mixed gas insulating medium

A trifluoroiodomethane and insulating medium technology, which is applied in the direction of insulators, inorganic gases, inorganic insulators, etc., can solve the problems of reduced gas insulation capacity, unfriendly environment, and serious greenhouse effect of gases, and achieve excellent insulation performance and good environmental protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method proposed by the present invention emphasizes the sequence and position of inflation, that is, the dense CF 3 I, c-C 4 f 8 The gas is first filled into the closed container from the top, and the CO with low density 2Fill from the bottom, which reduces the mixing rest time and makes the gas mix more uniform.

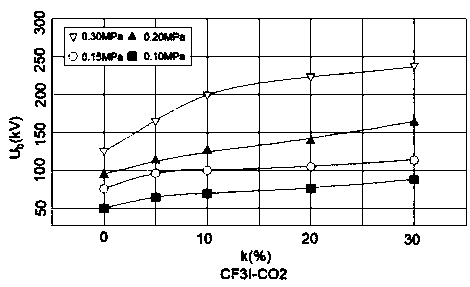

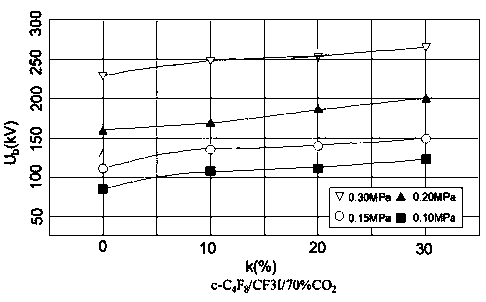

[0034] When the power frequency breakdown voltage of CF3I / CO2 mixed gas exceeds 20%, the insulation performance of CF3I gas will change little if the CF3I content continues to increase. After fixing the CO2 gas to 70% in the CF3I / CO2 mixed gas, reducing the CF3I gas content, the insulation ability of the mixed gas is improved after adding c-C4F8, and the insulation performance of the mixed gas is basically the same when the c-C4F8 mixed gas reaches 10%. Therefore, when the content of c-C4F8 is higher than 10%, the overall improvement of the insulation performance of the mixed gas is small. Since the GWP of the c-C4F8 gas is 8900, increasing...

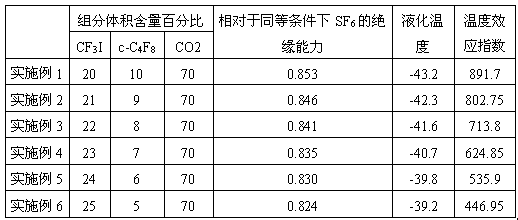

Embodiment 1

[0037] Take CF3I, c-C4F8 and CO2 to physically mix at room temperature to obtain an environmentally friendly mixed gas insulating medium. In this insulating medium, the volume fraction of CF3I is 20%, the volume fraction of c-C4F8 is 10%, and CO2 The volume fraction is 70%. The method to obtain this environment-friendly insulating medium is to first pump the closed container to a vacuum state below 10Pa in any metal airtight container with a height less than 30m, and then flush c-C4F8, CF3I, and CO2 gases in sequence. The mixed gas was left to stand for 48 hours to mix well.

Embodiment 2

[0039] Take CF3I, c-C4F8 and CO2 to physically mix at room temperature to obtain an environmentally friendly mixed gas insulating medium. In this insulating medium, the volume fraction of CF3I is 21%, the volume fraction of c-C4F8 is 9%, and CO2 The volume fraction is 70%. The method to obtain this environment-friendly insulating medium is to first pump the closed container to a vacuum state below 10Pa in any metal airtight container with a height less than 30m, and then flush c-C4F8, CF3I, and CO2 gases in sequence. The mixed gas was left to stand for 48 hours to mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com