Thermal bulb of thermal expansion valve, filling method thereof and refrigerating system with same

A technology of thermal expansion valve and refrigeration system, which is applied in the direction of material expansion/contraction thermometers, refrigerators, refrigeration components, etc., which can solve the problems of high superheat, large change of static superheat, and low energy efficiency ratio of refrigeration systems. Achieve high energy efficiency ratio and small change in superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

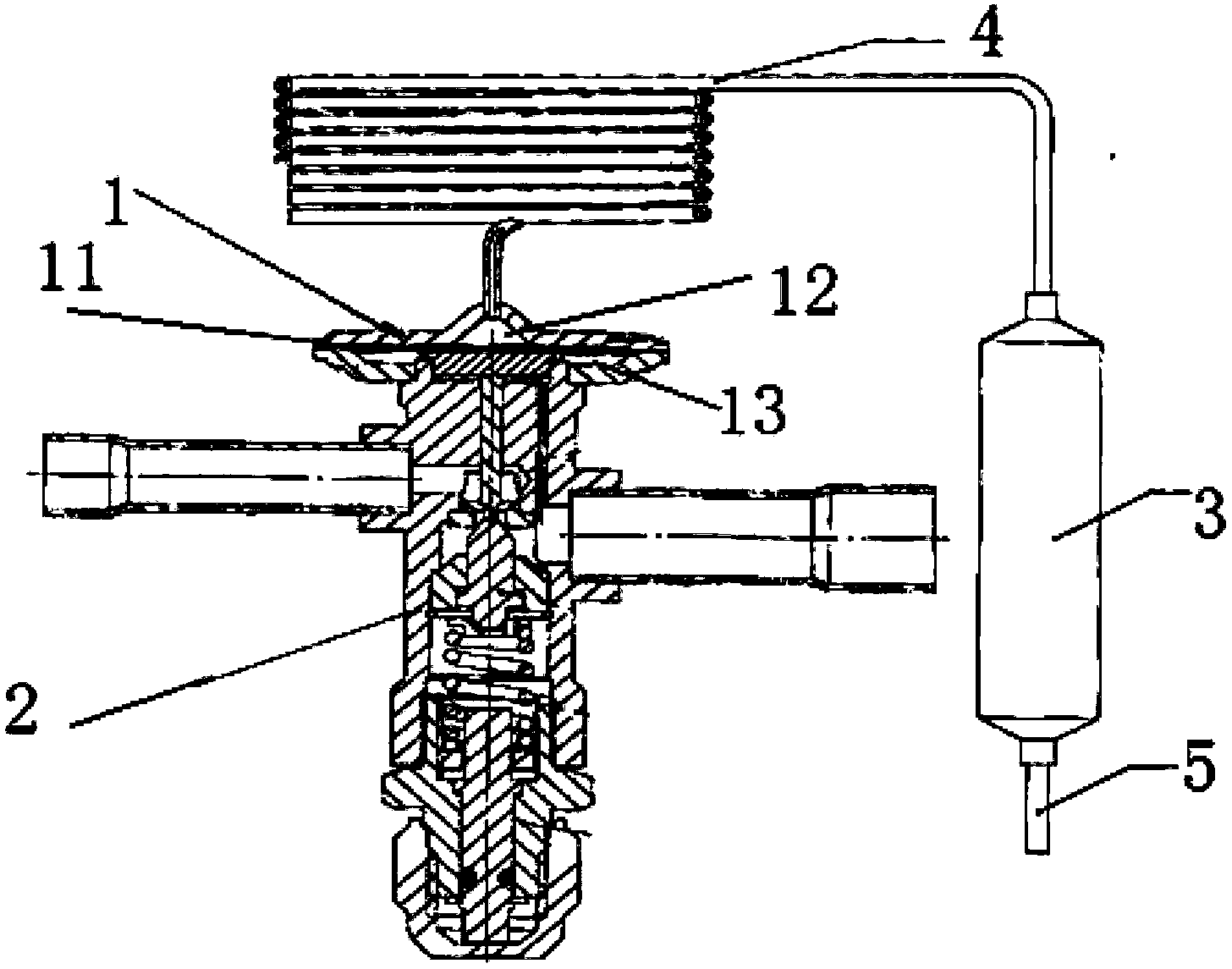

Image

Examples

Embodiment 1

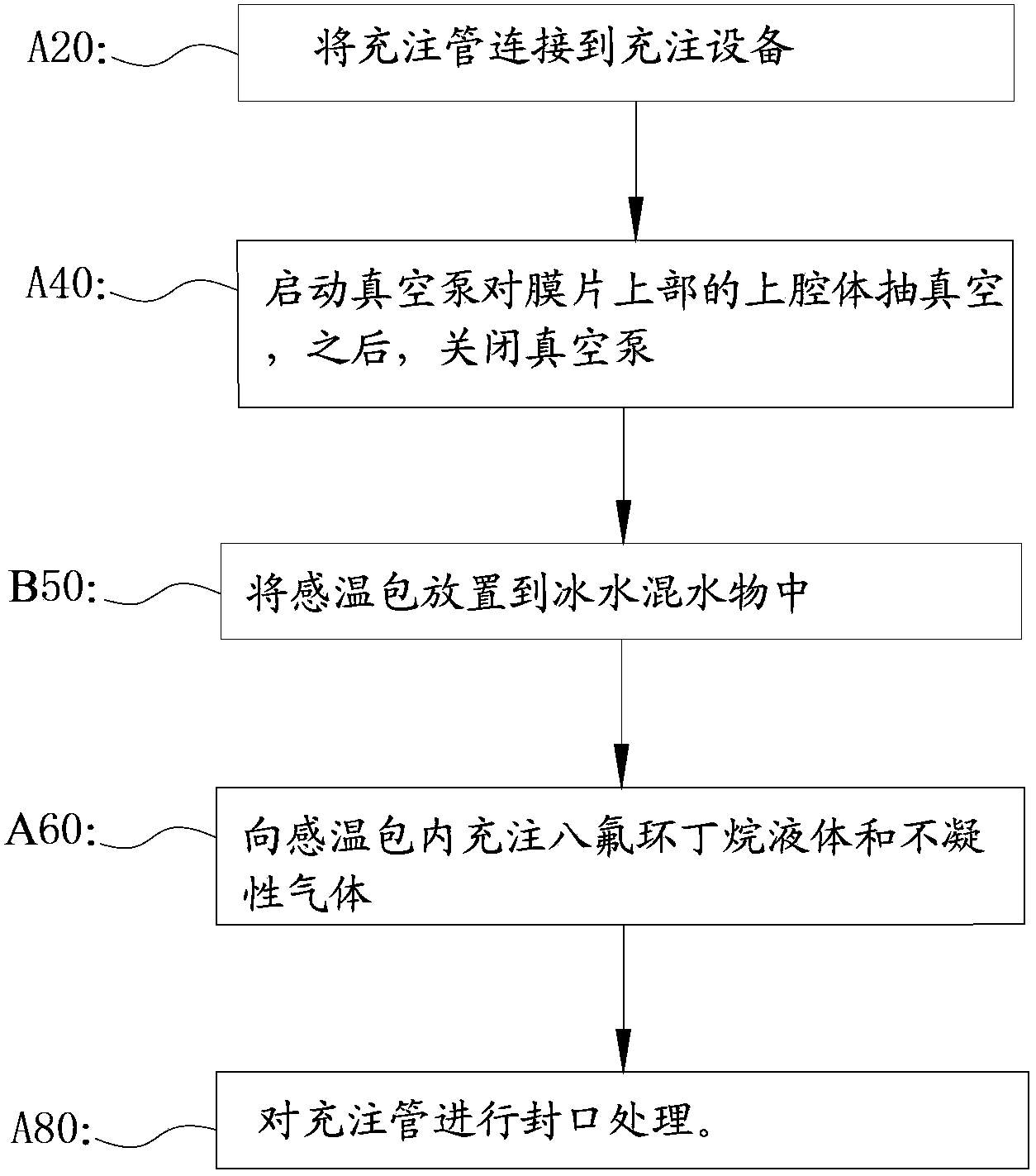

[0031] Such as figure 2 It is a flow chart of the first specific embodiment of the filling method of the temperature sensing bulb of the present invention. The filling method of the temperature-sensing bulb of the thermal expansion valve of the present embodiment 1 comprises the following steps:

[0032] A20: At room temperature, connect the filling tube 5 to the filling equipment;

[0033] A40: Start the vacuum pump to evacuate the upper cavity 12 above the diaphragm 11 to below -0.095MPa, and then turn off the vacuum pump;

[0034] A50: Put the temperature-sensing package 3 into the ice-water mixture to keep the ambient temperature of the temperature-sensing package 3 at zero degrees.

[0035] A60: Fill the temperature sensing bulb 3 with octafluorocyclobutane liquid and non-condensable gas. Specifically, first fill a certain weight of liquid octafluorocyclobutane into the temperature-sensitive package 3, and then fill a certain pressure of non-condensable gas into the t...

Embodiment 2

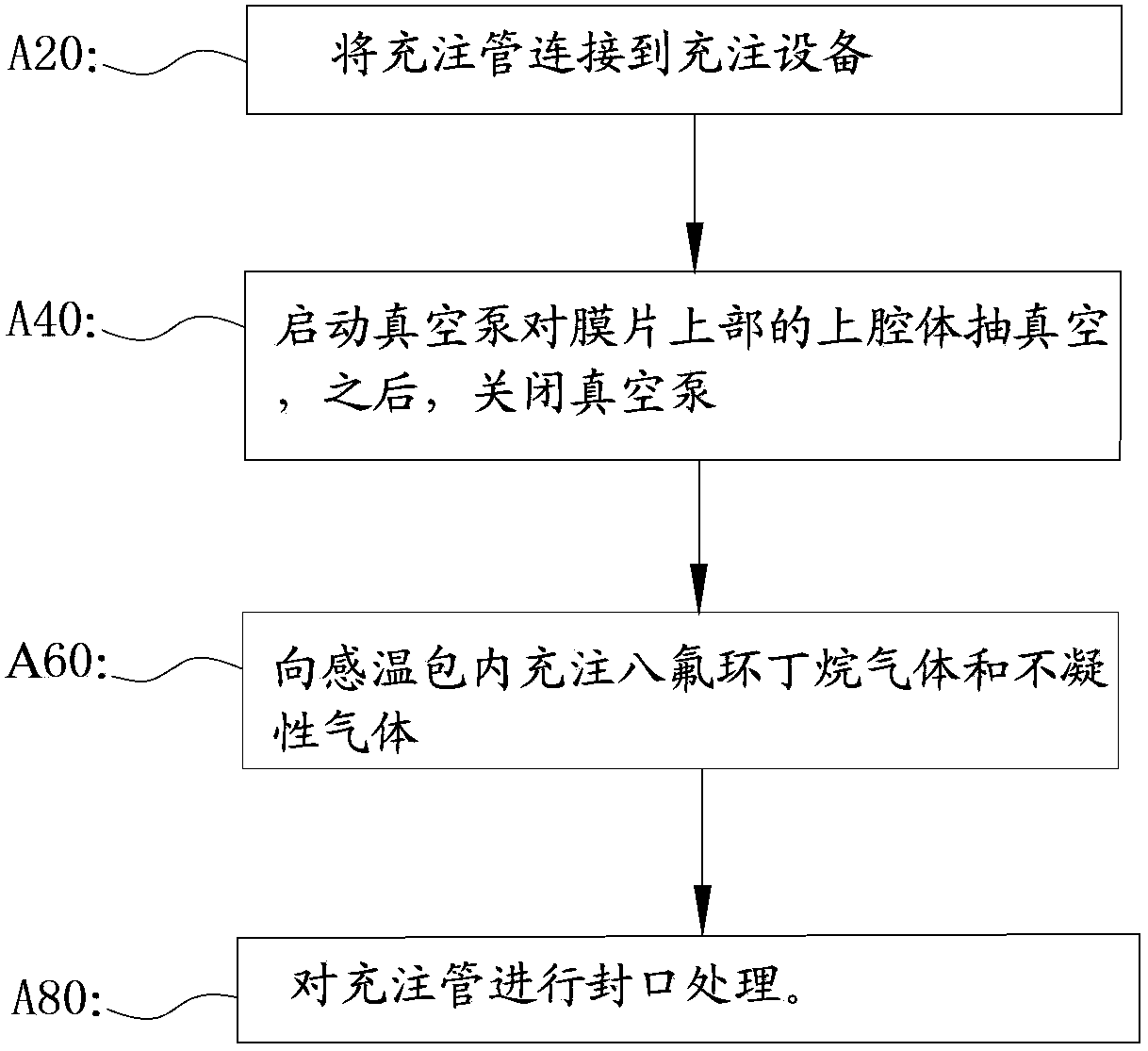

[0038] Such as image 3 It is a flow chart of the second specific embodiment of the filling method of the temperature sensing bulb of the present invention. The filling method of the temperature-sensing bulb of the thermal expansion valve in the second embodiment specifically includes the following steps:

[0039] A20: At room temperature, connect the filling tube 5 to the filling equipment;

[0040] A40: Start the vacuum pump to evacuate the cavity above the diaphragm to below -0.095MPa, then turn off the vacuum pump;

[0041] A60: Fill the temperature sensing bag 3 with octafluorocyclobutane gas and non-condensable gas. Specifically, octafluorocyclobutane at a certain pressure is filled into the temperature sensing bulb 3 first, and then non-condensable gas at a certain pressure is filled into the temperature sensing bulb 3 .

[0042] A80: Seal the filling tube 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com