Roll ball high-speed electronic spindle

A high-speed motorized spindle and ball technology, used in clamping, support, positioning devices, etc., can solve the problems of lowering the spindle temperature, low speed of the ball motorized spindle, single structure, etc., and achieve the effect of satisfying high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

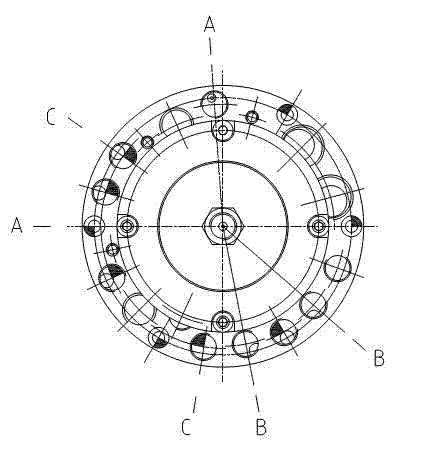

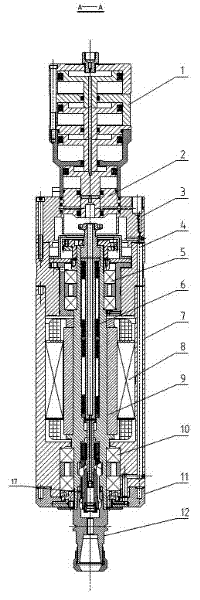

[0062] Such as Figure 1 to Figure 30 As shown in each figure, the opening of the upper part of the body 7 of the present invention is connected and fixed with a bearing block assembly 4, and the middle through hole of the bearing block assembly 4 is fixed with an upper bearing assembly 5, and the lower part of the upper bearing assembly 5 is provided with a stator 8. The lower cavity of 7 is provided with a lower bearing assembly 10, the lower part of the lower bearing assembly 10 is fixed with the lower cover assembly 11 of the body, and the bottom of the lower cover assembly 11 of the body is fixed with a dust cover 13; the upper part of the bearing seat assembly 4 is fixed with an aluminum water jacket Component 3, the opening of the upper cavity of the aluminum water jacket component 3 is fixed with an air guide plug 2, the upper part of the air guide plug 2 is fixed with a knife unloading cylinder 1, and there is a shaft core component 9 below the bottom piston of the kni...

Embodiment 2

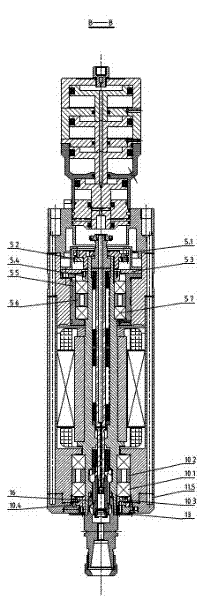

[0064] Same as Embodiment 1, except that the contact surface between the air guide plug 2 and the inner wall of the aluminum water jacket assembly 3 is provided with an O-shaped sealing ring, and the contact surface between the air guide plug 2 and the bottommost piston of the unloading cylinder 1 All are provided with a star-shaped sealing ring; the knife unloading cylinder 1 includes a cylinder top cover 1.1, the middle part of the cylinder top cover 1.1 is provided with an intake pipeline connection screw hole 1.8, the first stage piston 1.2 at the bottom of the cylinder top cover 1.1, and the second stage piston 1.11, third-stage piston 1.13, segmented piston 1.6, first-stage cylinder 1.3, second-stage cylinder 1.12, lowest-stage cylinder 1.4, the contact points between the first-stage, second-stage and third-stage pistons and all stages of cylinders are uniform A sealing ring 1.10 is provided, locking screws 1.9 are provided on the inner walls between the cylinders at all ...

Embodiment 3

[0066] Same as Embodiment 1, except that the aluminum water jacket assembly 3 includes an aluminum water jacket bearing seat 3.3, a protruding sealing ring 3.4 of the aluminum water jacket bearing seat 3.3, and an axial The through piston hole 3.2, the inner wall of the piston hole 3.2 is provided with a piston sealing ring 3.6, the positioning step 3.8 at the bottom of the aluminum water jacket bearing seat 3.3, the aluminum water jacket inner cavity 3.7 inside the aluminum water jacket bearing seat 3.3, the aluminum water jacket bearing seat The outer ring wall on 3.3 also includes cylinder broach hole 3.1, knife unloading dust blowing hole 3.5, coolant inlet and outlet hole 3.9, lubricating oil recovery hole 3.10, upper bearing lubricating oil inlet hole 3.11, power cord installation hole 3.12, cylinder Install connection hole 3.13, ground wire connection position 3.14, air seal hole 3.15, lower bearing lubricating oil inlet hole 3.16 and aluminum water jacket installation h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com