High-purity octafluorocyclobutane purification method and system

A technology of octafluorocyclobutane and purification method, which is applied in the field of purification of high-purity octafluorocyclobutane, can solve problems such as difficulties, failure to achieve rectification purification, low purity, etc., and achieve simple structure, high product purity, Simple process and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention are given below to further describe the composition of the present invention in detail.

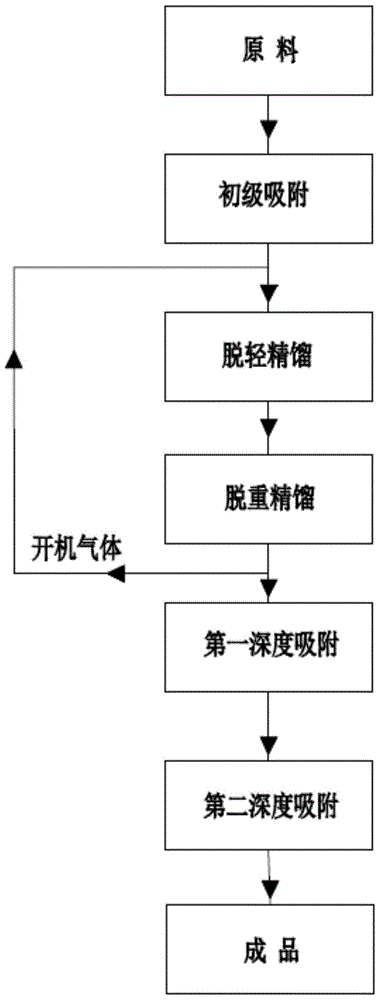

[0026] The purification method of the high-purity octafluorocyclobutane of the present embodiment comprises the following steps successively:

[0027] Step A, system cleaning, purging the purification system with nitrogen gas, and vacuumizing the purification system after purging. Because there are various impurities in the whole purification system, these impurities may affect the purification effect of the octafluorocyclobutane product, therefore, the whole purification system needs to be purged with inert gas nitrogen; in addition, in order to allow The mixed gas inside the purification system is reduced, and the feed rate is increased, and the purification system is vacuumed until the gas pressure inside the system is below 5pa.

[0028] Step B1, the initial stage of adsorption, the raw material is adsorbed by the primary adsorber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com