Coating process for lotus leaf-like diamond film

A diamond-like film and process technology, which is applied in the direction of metal material coating process, superimposed layer plating, gaseous chemical plating, etc., can solve the problems of poor thermal stability, insufficient satisfaction, large internal stress, etc., and achieve fatigue life improvement , reduce internal stress, improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

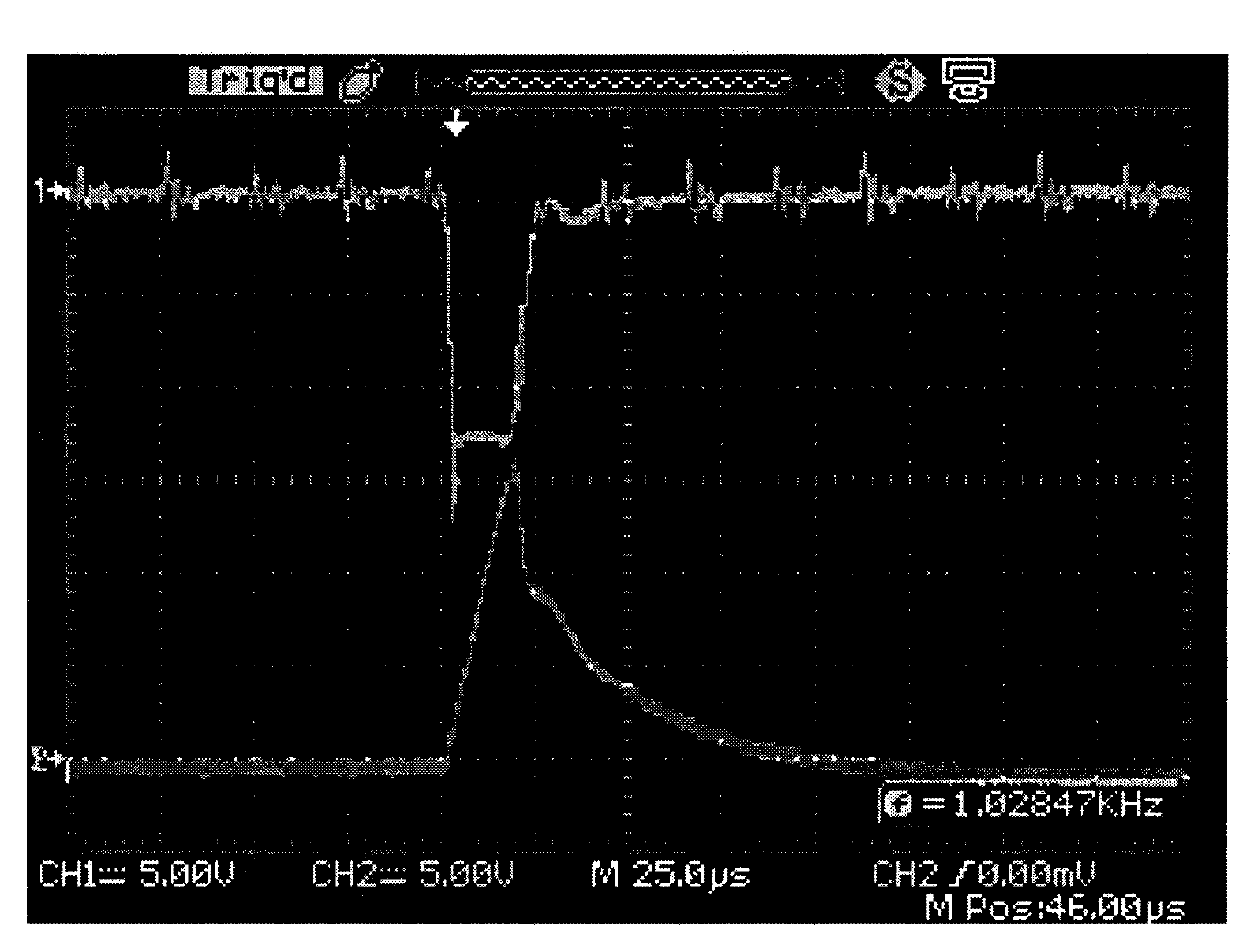

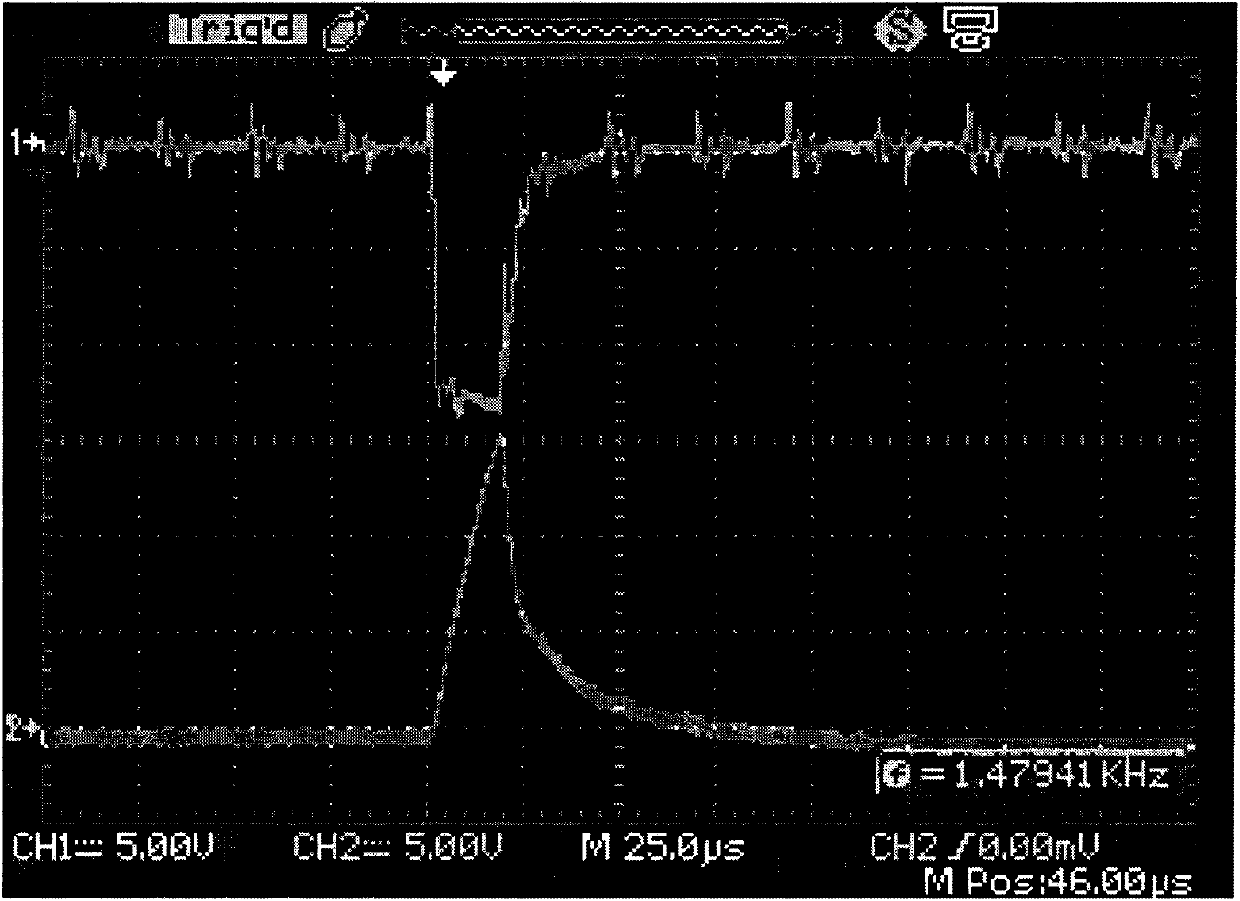

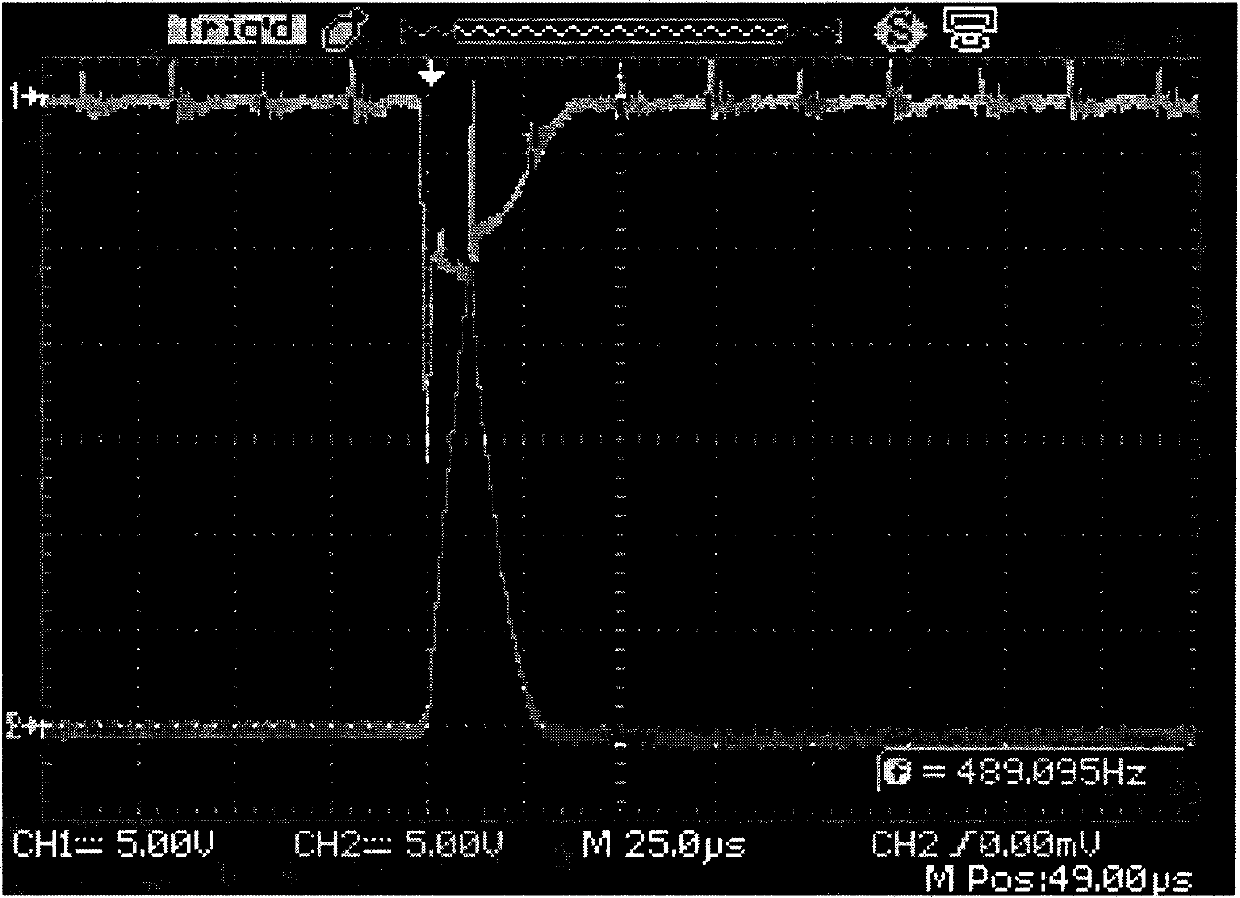

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention are described below to facilitate the understanding of those skilled in the art.

[0044] A coating process for preparing a lotus leaf diamond-like film, the specific steps are as follows:

[0045] (1) Cleaning and drying of the workpiece surface

[0046] It is very important to clean the surface of the workpiece before coating, which is directly related to the bonding force of the lotus leaf diamond-like film. In addition, the rust and stains on the surface will also cause the surface to spark during the plasma cleaning and coating process, thus leaving a residue on the surface of the workpiece. Arc spots, which are all to be avoided. There are different processes for cleaning different workpieces. The specific steps are as follows:

[0047] Divide the workpiece surface condition into three types: (A) rough surface workpiece containing oxide and phosphide; (B) smooth surface workpiece containing oxide and phosphide; (C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com