Process for manufacturing micro-lens array with large numerical aperture

A technology of microlens array and numerical aperture, which is applied in the fields of lenses, optics, instruments, etc., can solve the problems of difficult large-area preparation, high cost, and unsatisfactory numerical aperture and other parameters, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

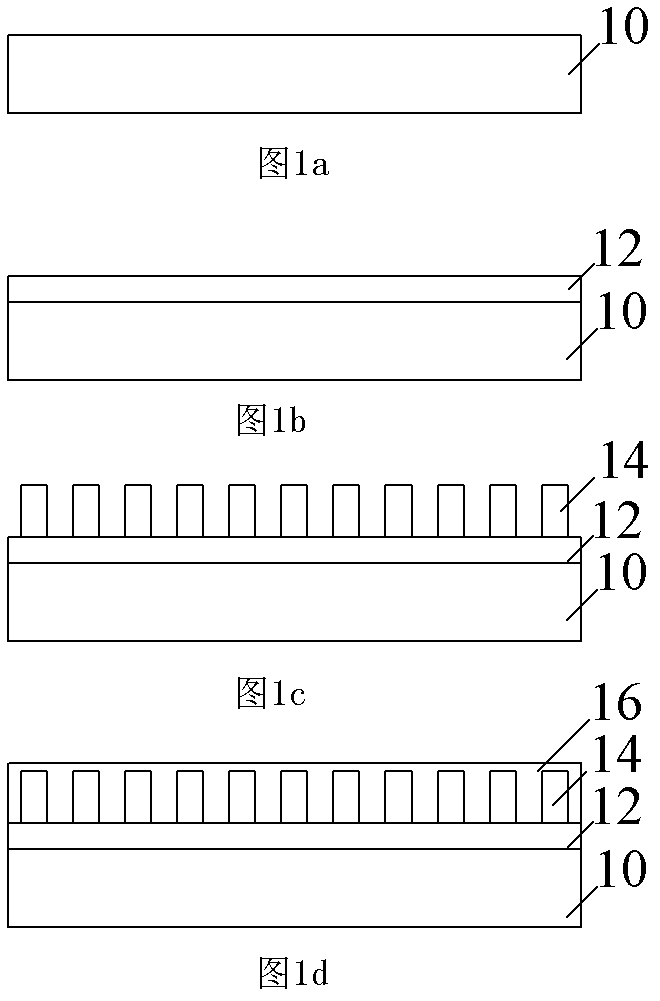

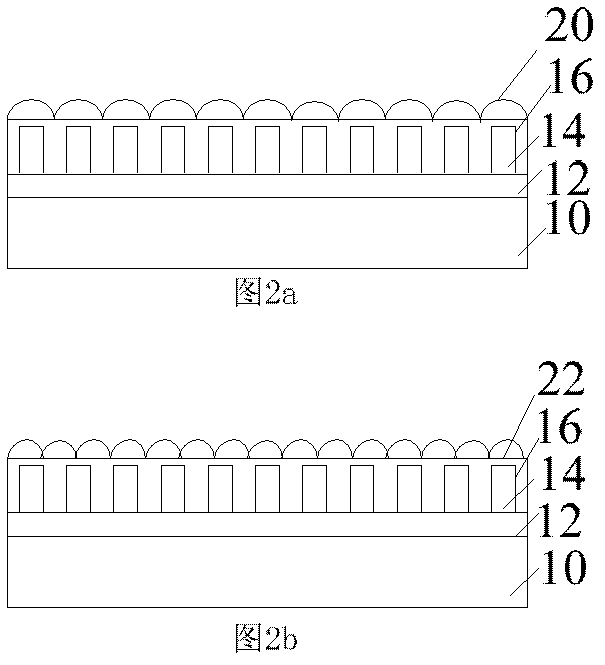

[0031] see Figure 1-4 , the technical process of preparing a large numerical aperture microlens array by inkjet printing disclosed in this patent includes the following steps:

[0032] (1) In the substrate cleaning step, the substrate glass is ultrasonically cleaned with detergent, deionized water and acetone-ethanol solution, and then the substrate is dried under an infrared lamp.

[0033] (2) if figure 1 As shown in b, a layer of ZnO amethyst layer is sputtered on the glass slide by radio frequency magnetron sputtering at room temperature. After the sputtering speed (power) is adjusted, the longer the sputtering time, the thicker the obtained amethyst layer; In this embodiment, the sputtering time is 5 minutes, and the thickness of the purple gold layer is about 100 nanometers.

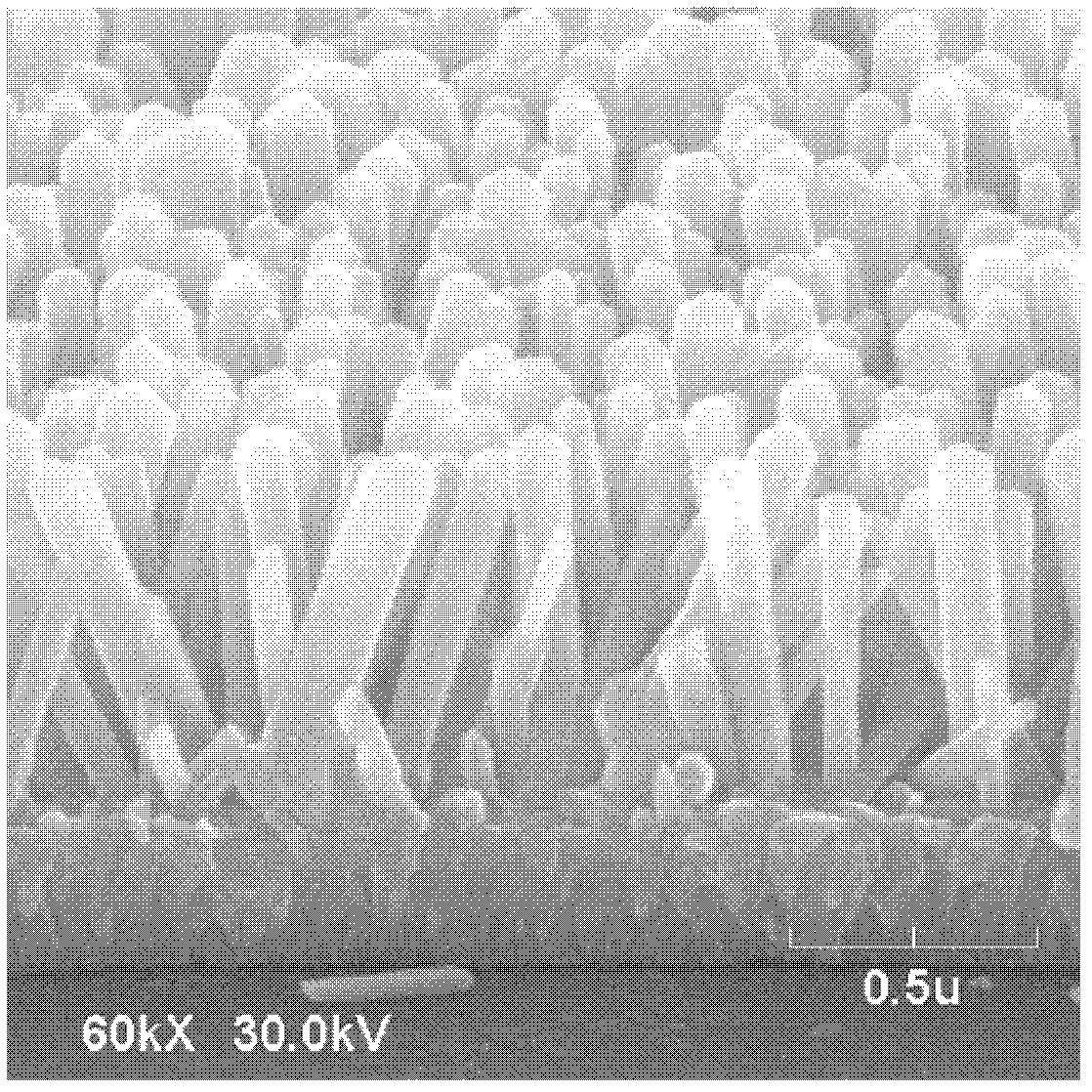

[0034] (3) if figure 1 As shown in b, ZnO nanocolumns are grown in a water bath on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com