Method for manufacturing high-performance nano friction generator

A nano-friction and generator technology, which is applied in the direction of friction generators, etc., to achieve the effects of excellent process compatibility, high yield, and improved output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

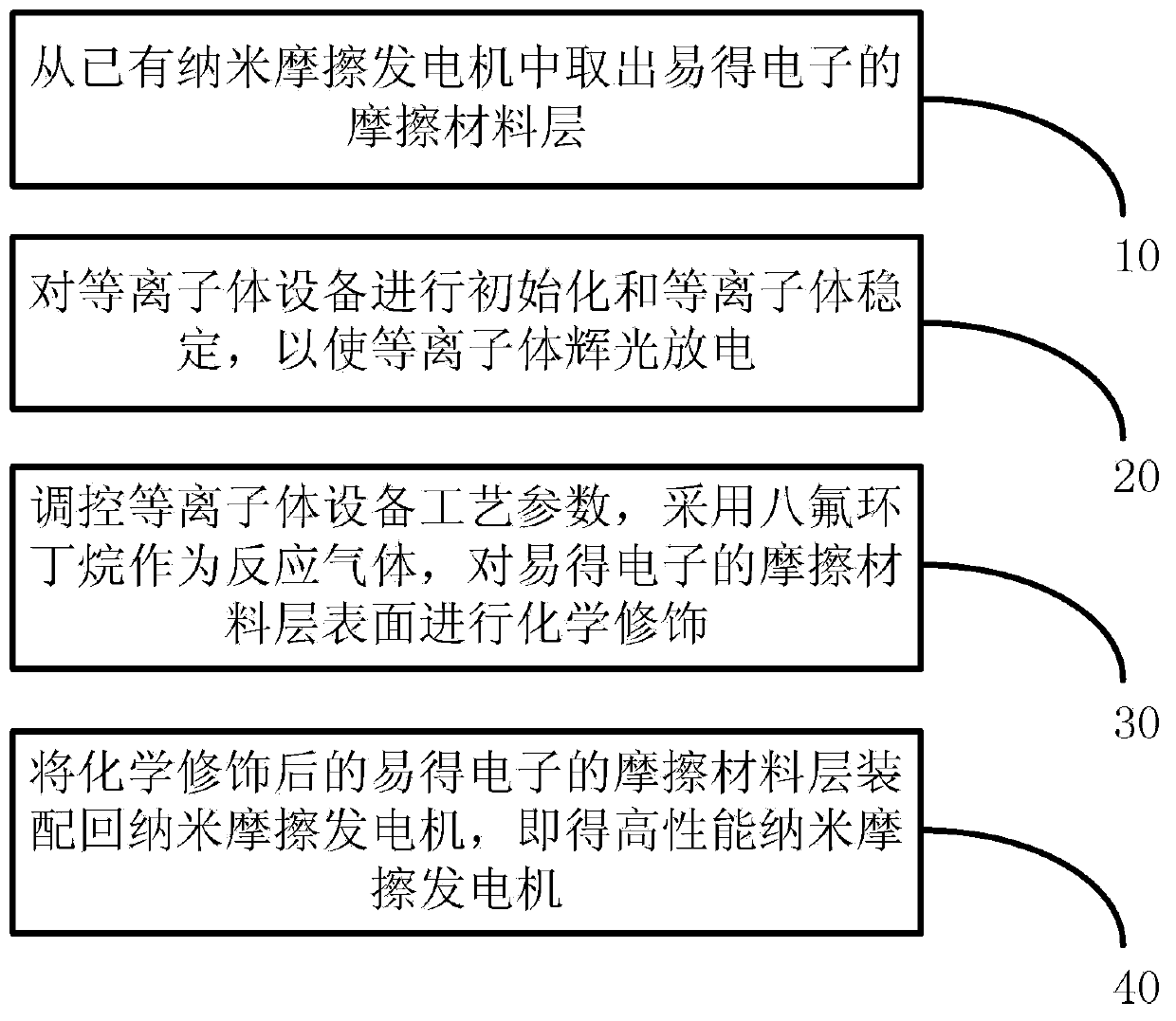

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. Attached below Figure 1-Figure 3 The specific steps of the preparation method of a high-performance nano triboelectric generator provided by the present invention are described.

[0027] refer to figure 1 , figure 1 It is a process flow chart of a preparation method of a high-performance nano-friction generator proposed by the present invention, and the specific steps are as follows:

[0028] Step 1: Take out the friction material layer that is easy to get electrons from the nano triboelectric generator;

[0029] refer to figure 2 (a), the friction layer of the existing nano-triboelectric generator is metal aluminum (Al) and polydimethylsiloxane (PDMS). According to the sequence list of electron g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com