Multicomponent mixture work medium suitable for fractional condensation type heat pump circulation system

A condensing type and working fluid technology, which is applied in the direction of heat exchange materials, fluid heaters, lighting and heating equipment, etc., can solve the problem of affecting the reliability of compressors, does not involve mixed working fluids, and has not found patent reports on mixed refrigerants And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

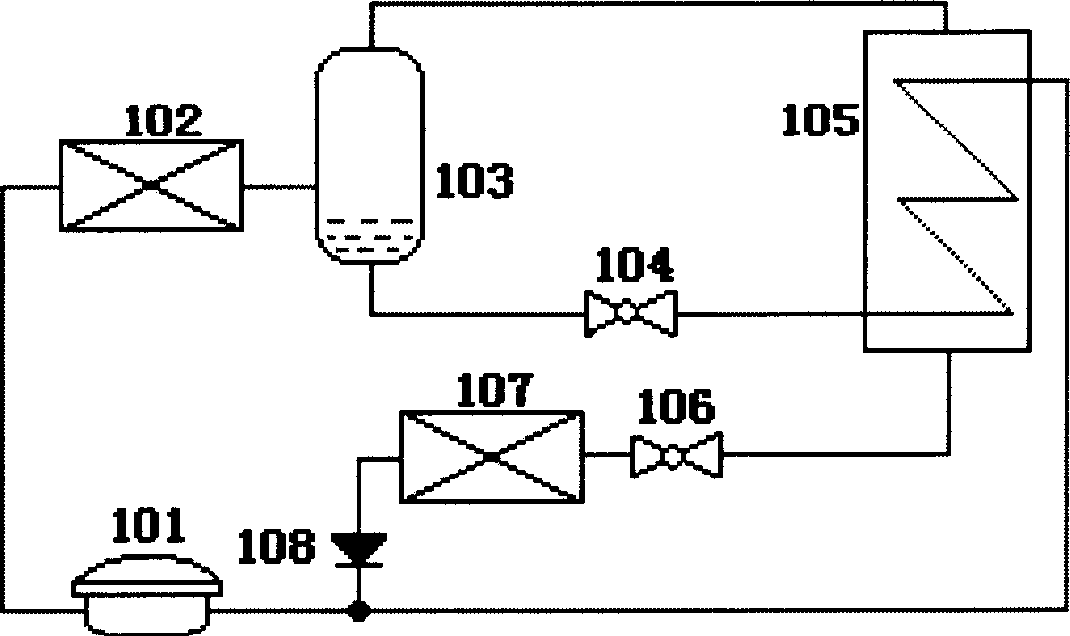

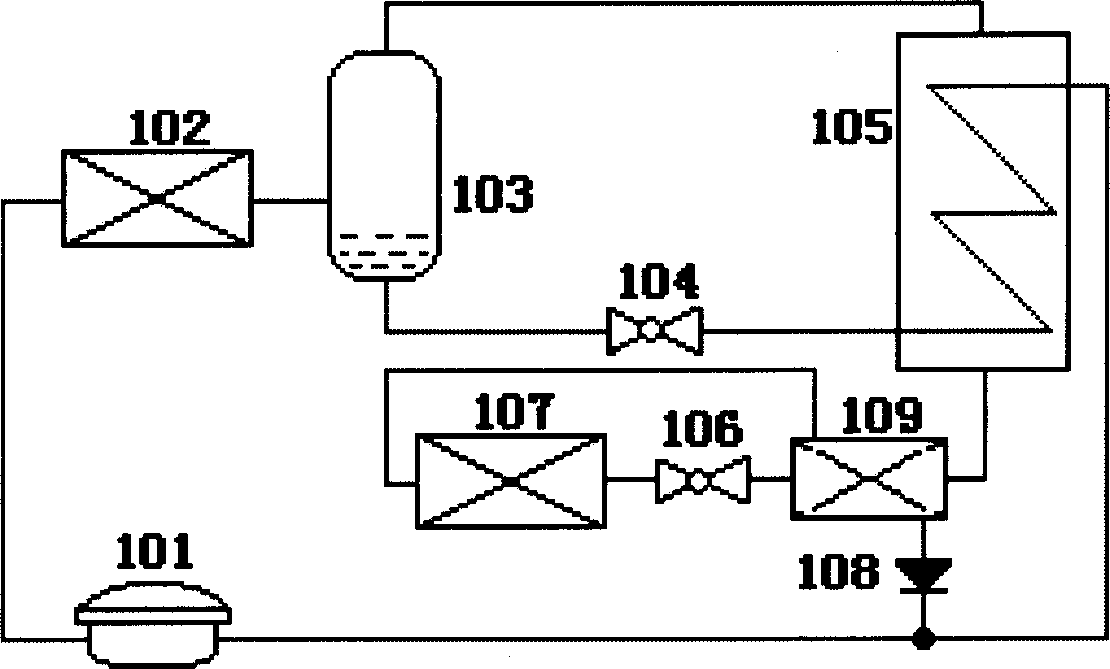

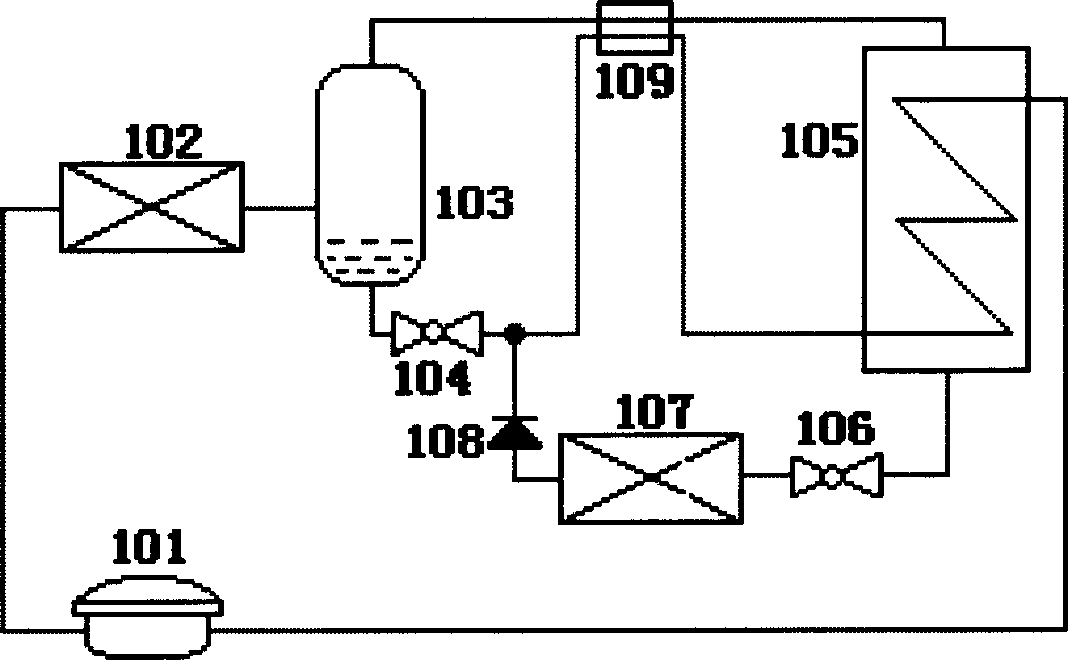

[0015] The ambient temperature is between -20°C and -10°C, and the condensing heat pump system produces heat in the temperature range of 60°C to 70°C. The cycle flow is as follows: figure 1 As shown, the mass concentration and performance of the mixed working fluid are shown in Table 1, where COP represents the heating efficiency of the system:

[0016] project

Embodiment 2

[0018] The ambient temperature is between -20°C and -10°C, and the condensing heat pump system produces heat in the temperature range of 70°C to 80°C. The cycle flow is as follows: figure 1 As shown, the mass concentration and performance of the mixed working fluid are shown in Table 2, where COP represents the heating efficiency of the system:

[0019] project

[0020] COP

Embodiment 3

[0022] The ambient temperature is between -10°C and 0°C, and the condensing heat pump system produces heat in the temperature range of 70°C to 80°C. The cycle flow is as follows: figure 1 As shown, the mass concentration and performance of the mixed working fluid are shown in Table 3, where COP represents the heating efficiency of the system:

[0023] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com