Process for implementing tetrafluoroethylene monomer continuous analysis applying on-line chromatographic technique

A tetrafluoroethylene and chromatographic technology, which is used in the analysis field of on-line gas chromatography in the continuous production process of tetrafluoroethylene monomer, can solve the problems such as difficulty in analyzing the content of main impurities in the purity of tetrafluoroethylene monomer, and achieves improved real-time sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below.

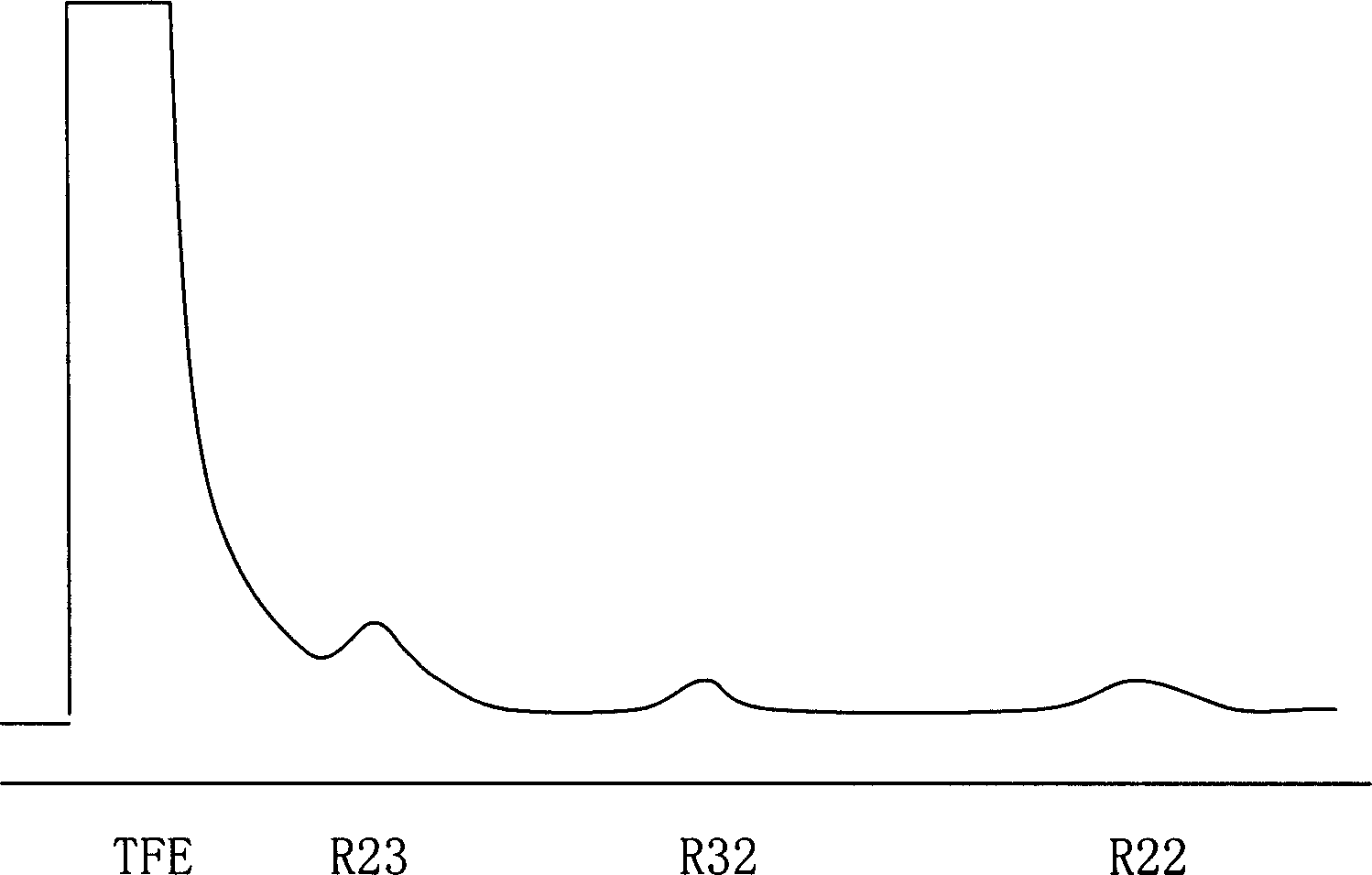

[0020] The present invention adopts VISTA2000 online chromatograph of ABB company, FID detector,

[0021] 1) Selection conditions: chromatographic column: a packed column with a ratio of 30% of Apisone immobilized on activated alumina; chromatographic column temperature: 70°C; detector temperature: 80°C; carrier gas: 99.9999% by volume Nitrogen; gas: hydrogen with a volume percentage of 99.9999%; supporting gas: air; carrier gas pressure and flow matching are operated according to the instructions;

[0022] 2) Standard sample preparation: Inject 5ml of tetrafluoroethylene with a volume percentage greater than 99.99% in the sampling bladder full of nitrogen, inject each 5ml of difluorochloromethane (CHF) with a volume percentage greater than 99.99% with a syringe 2 Cl), trifluoromethane (CHF 3 ) and difluoromethane (CH 2 f 2 ), measure the total volume of gas in the bladder by the drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com