Method for synthesizing fire extinguishing agent octafluorocyclobutane

A technology of octafluorocyclobutane and fire extinguishing agent, which is applied in the field of organic chemical synthesis, can solve the problems of restricting industrial production of octafluorocyclobutane, restricting industrial production, and difficult preparation of raw materials, and achieves less industrial waste, cheap raw materials, and easy synthesis The effect of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

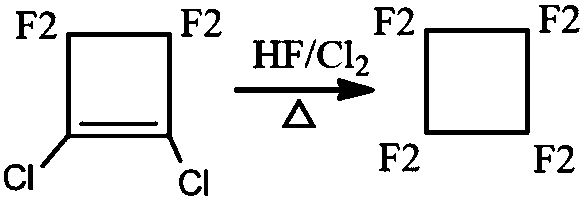

Image

Examples

Embodiment 1

[0019] (1) Preparation of fluorination catalyst: adopt co-precipitation method, the steps are as follows: CrCl 3 , In(NO 3 ) 3 , Zn(NO 3 ) 2 The solution is mixed into a mixed solution at a molar ratio of 90:5:5, then ammonia water accounting for 30% by weight of the mixed solution is added dropwise to the above mixed solution, the pH value of the mixed solution is adjusted to 9.0, and after 24 hours of precipitation aging, the precipitation filtering, washing with deionized water, drying, and pressing to obtain a Cr-In-Zn catalyst.

[0020] The drying process of Cr-In-Zn catalyst: 20ml Cr-In-Zn catalyst is loaded into the fixed-bed reactor, and then the fixed-bed reactor is heated with an open tube heating furnace. Under the protection of 50m / minl nitrogen, the Cr-In-Zn catalyst is first raised to 400°C at a rate of 10°C / min and dried for 10 hours, and then the temperature is lowered to 200°C, thus completing the Cr-In-Zn catalyst drying process.

[0021] Activation pro...

Embodiment 2

[0024] (1) Preparation of fluorination catalyst: adopt co-precipitation method, the steps are as follows: CrCl 3 , Co(NO 3 ) 2 , Mg(NO 3 ) 2 The solution is mixed into a mixed solution at a molar ratio of 90:5:5, then ammonia water accounting for 30% by weight of the mixed solution is added dropwise to the above mixed solution, the pH value of the mixed solution is adjusted to 9.0, and after 24 hours of precipitation aging, the precipitation filtering, washing with deionized water, drying, and pressing to obtain a Cr-Co-Mg catalyst.

[0025] The drying process of the Cr-Co-Mg catalyst: 20ml of Cr-Co-Mg catalyst was loaded into the fixed-bed reactor, and then the fixed-bed reactor was heated with an open tube heating furnace. Under the protection of 50m / minl nitrogen, the Cr-Co-Mg catalyst is first raised to 400°C at a rate of 10°C / min and dried for 10 hours, and then the temperature is lowered to 200°C to complete the Cr-Co-Mg catalyst drying process.

[0026] Activation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com