Device and method for automatic monitoring and screening of edge sealing system

An automatic monitoring and edge banding technology, which is applied in the field of gypsum board production, can solve problems that affect the production efficiency of gypsum boards and increase production workload, and achieve the effect of improving production efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

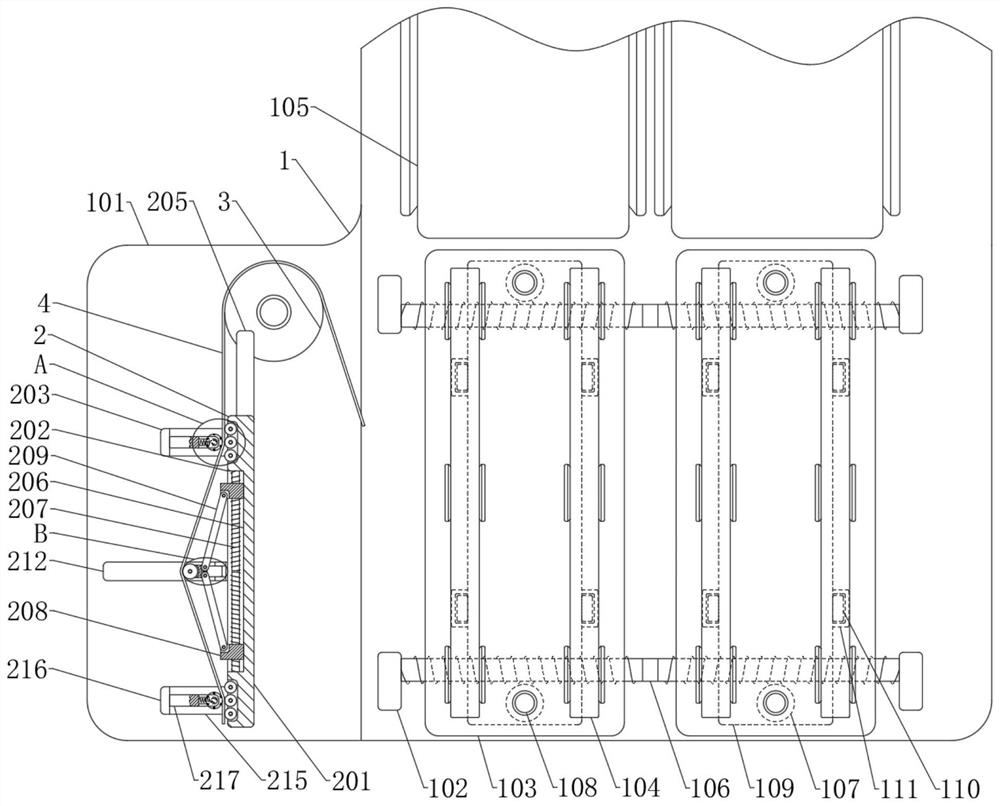

[0034] Such as Figure 1 to Figure 3As shown, the present invention provides a device for automatic monitoring and screening of the edge banding system, including a secondary stamping platform 1 arranged at the gypsum board conveying line and an edge sealing detection mechanism 2 arranged on the secondary stamping platform 1, The side of the edge detection mechanism 2 on the secondary stamping platform 1 is also provided with an edge wheel 3 for setting the edge band 4 to seal the plasterboard;

[0035] Among them, the edge detection mechanism 2 detects whether the edge band 4 is broken by detecting the rotation of the edge wheel 3 through a photoelectric sensor, and detects the fracture length through the movement of the edge band 4, and the secondary stamping platform 1 detects whether the edge band 4 is broken according to the fracture length of the edge band 4. Screen and continuously transport the gypsum boards on the gypsum board conveyor line to the corresponding area. ...

Embodiment 2

[0074] The present invention also provides a monitoring and screening method for an automatic monitoring and screening device of an edge banding system, comprising the steps of,

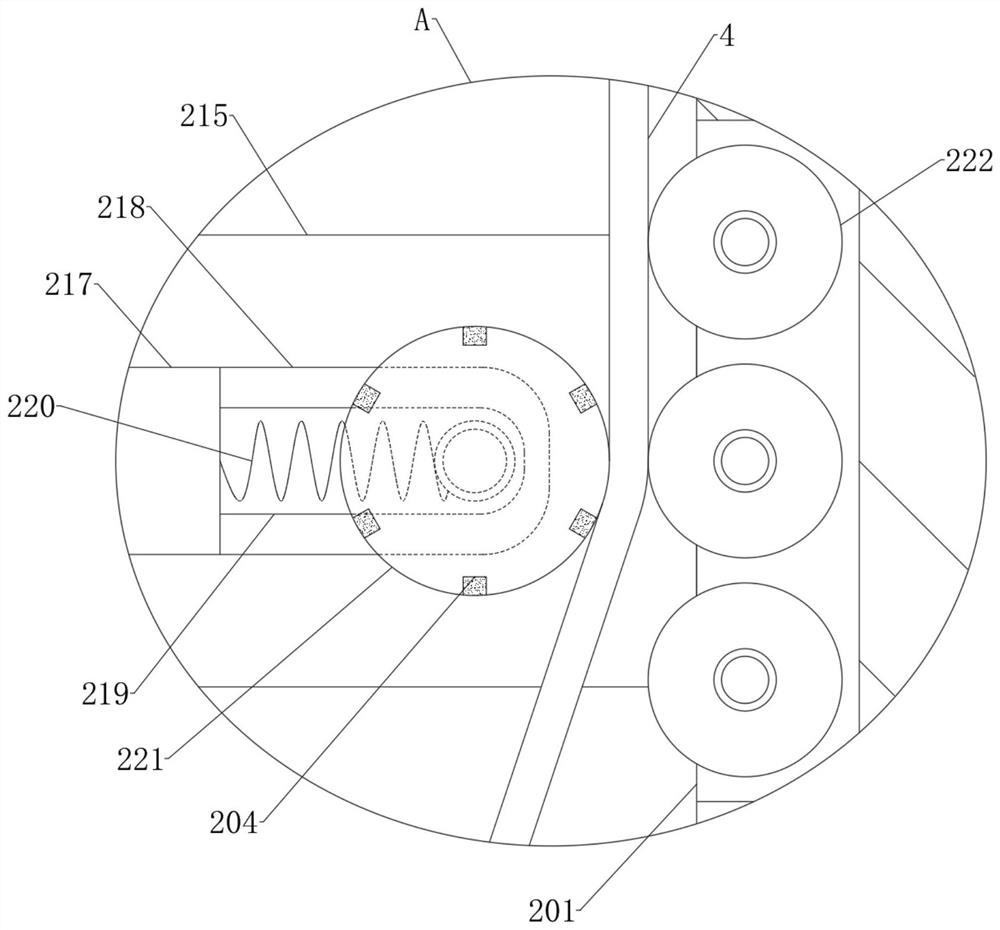

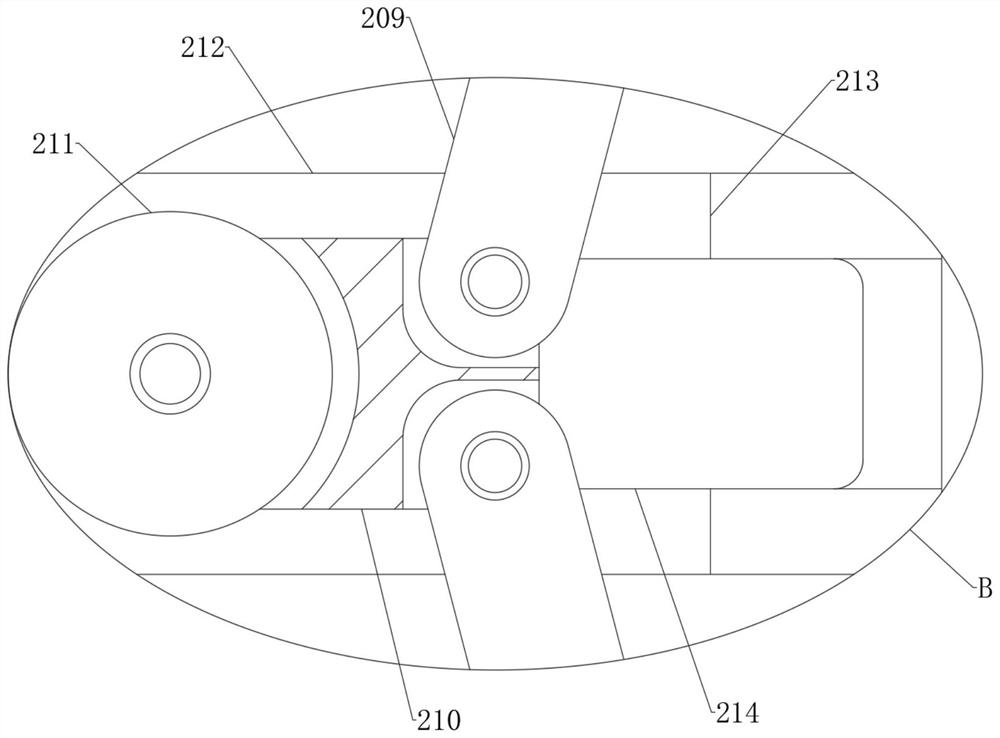

[0075] S100, the edge banding belt is set through the pressure roller, top roller and pressure roller in turn, and the rotation of the edge banding wheel is monitored by the photoelectric sensor to monitor the edge banding operation;

[0076] S200, when the edge banding is broken, the photoelectric sensor detects that the edge banding wheel gradually stops rotating, activates the movement detection unit to make the top roller drive the edge banding movement, when the sensing element detects the pressure between the edge banding and one of the pressure rollers When it disappears, judge the broken position of the edge band, and measure the length between the broken position of the edge band and the gypsum board by the number of rotations of the pressure roller;

[0077] S300, the secondary stacking pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com