Patents

Literature

65results about How to "Reduce overuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Patient monitor capable of monitoring the quality of attached probes and accessories

ActiveUS8255026B1Reduce capacityReduce the possibilityDiagnostic recording/measuringSensorsQuality controlPulse oximetry

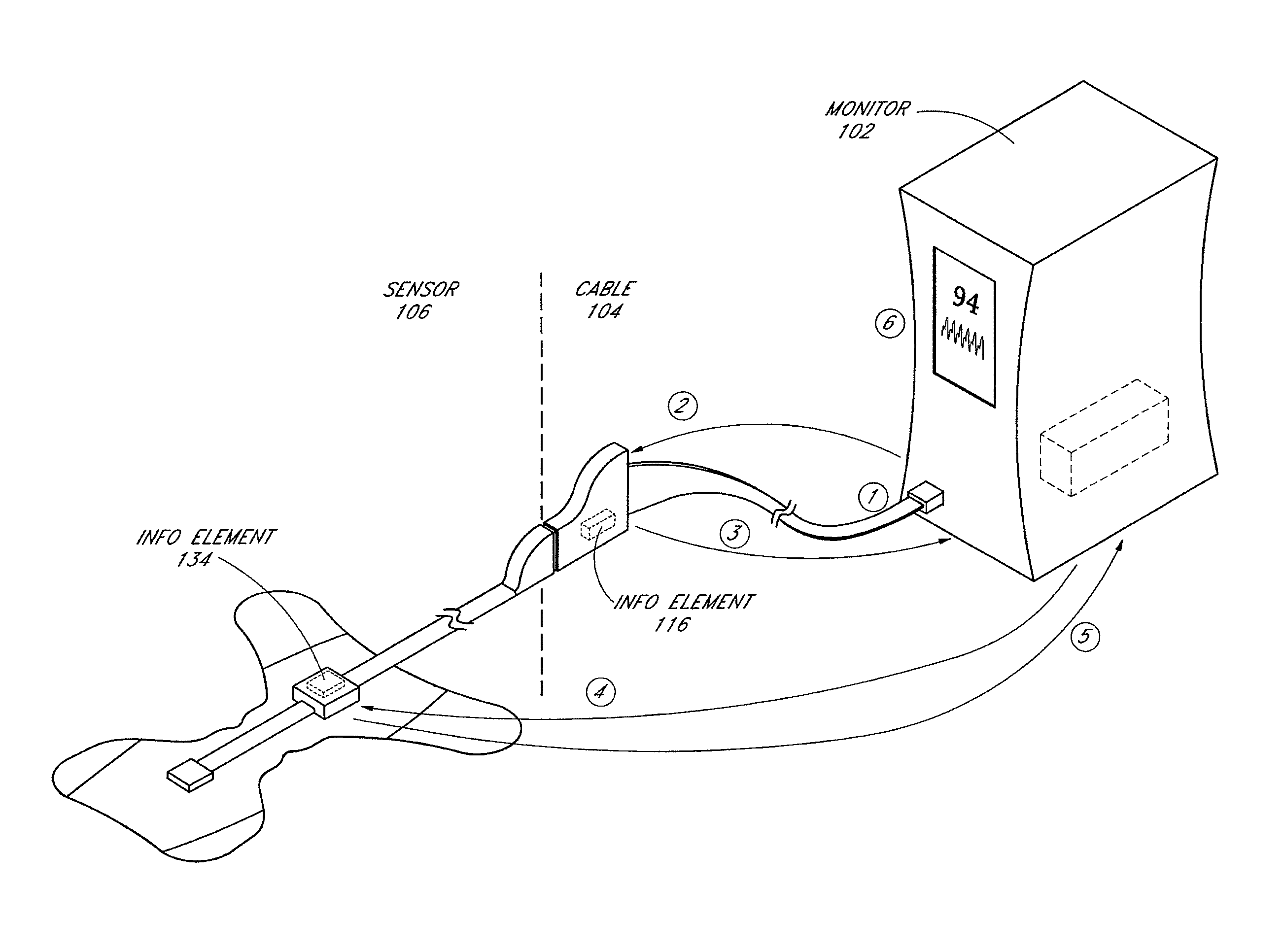

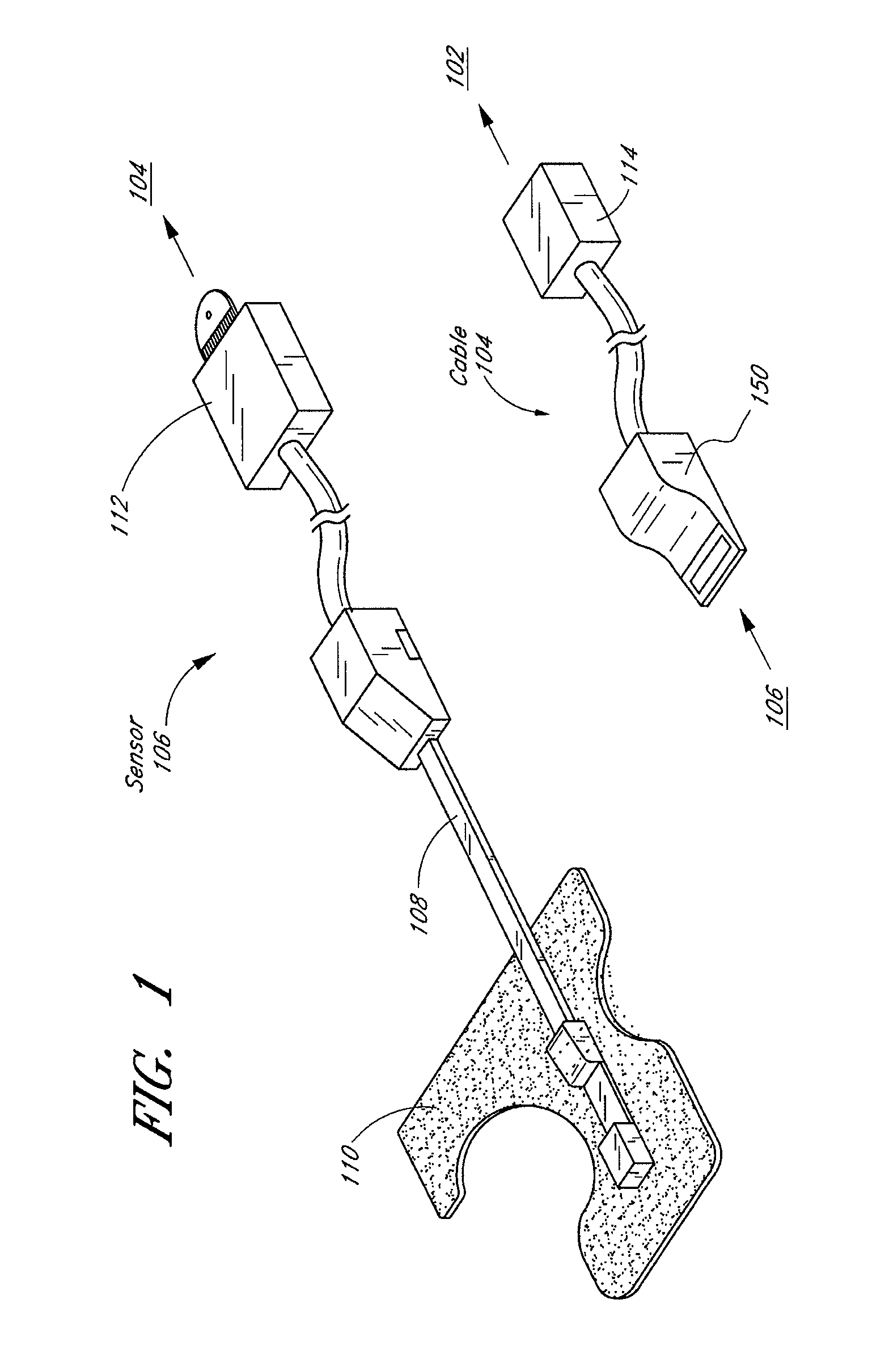

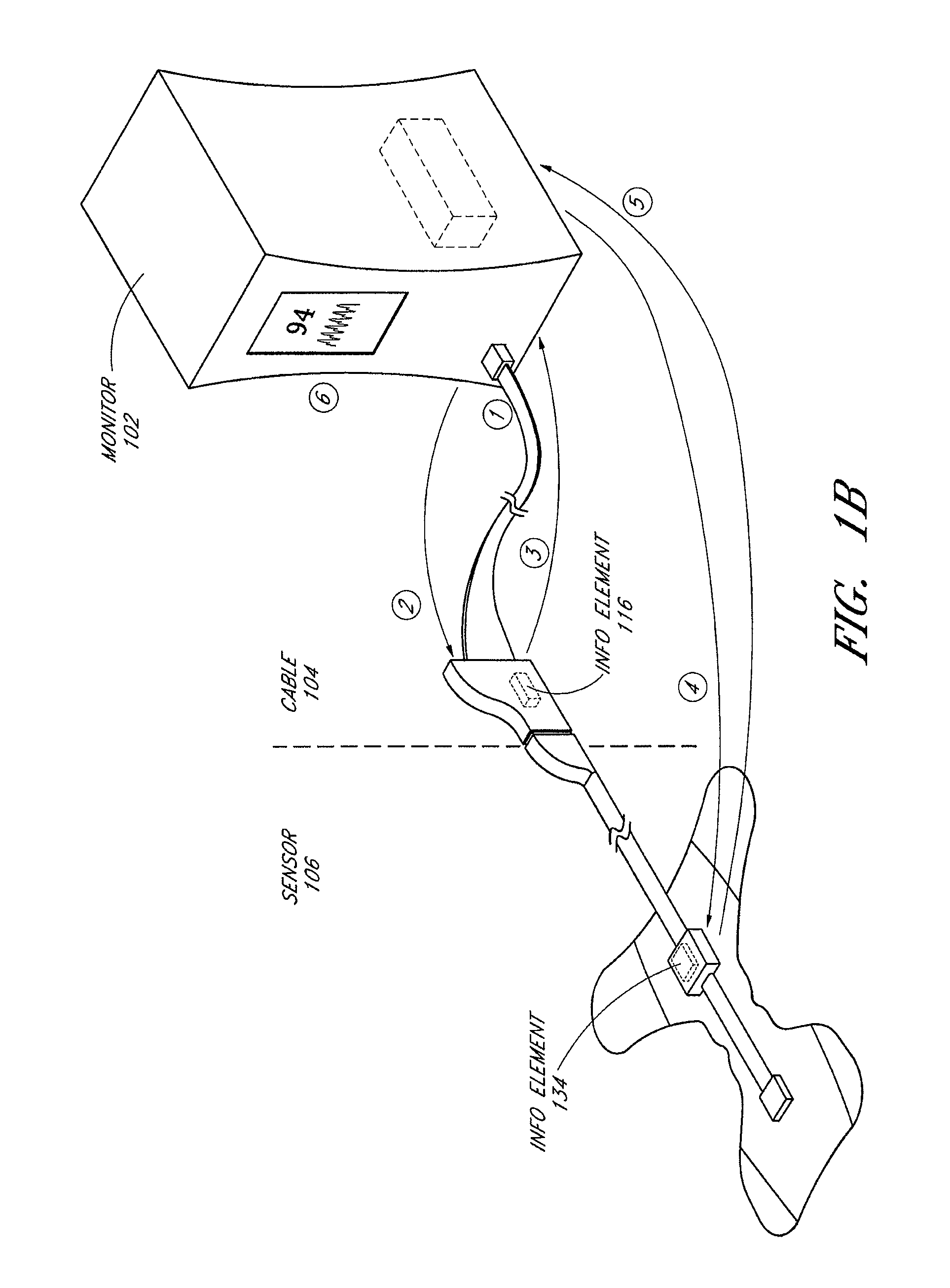

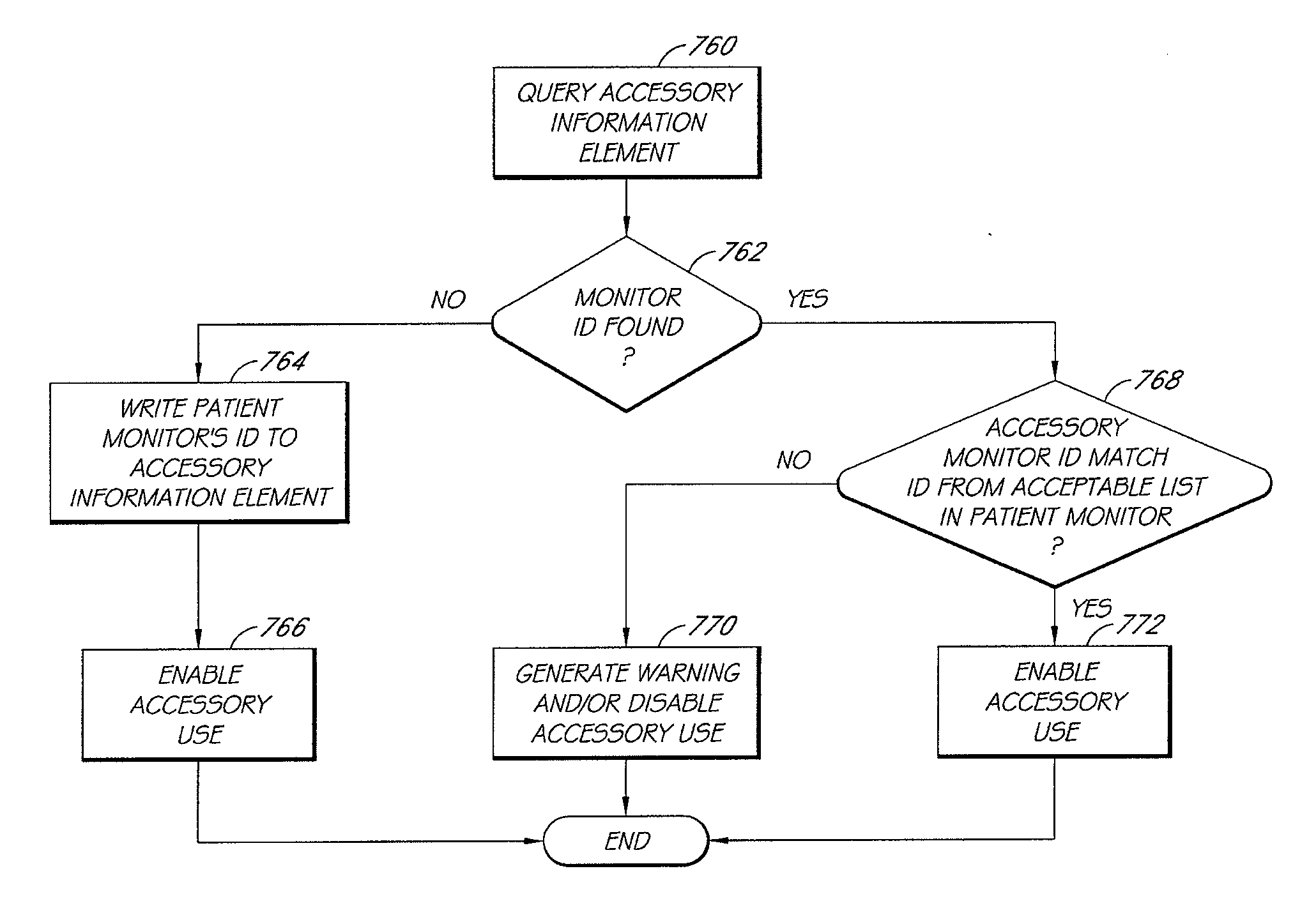

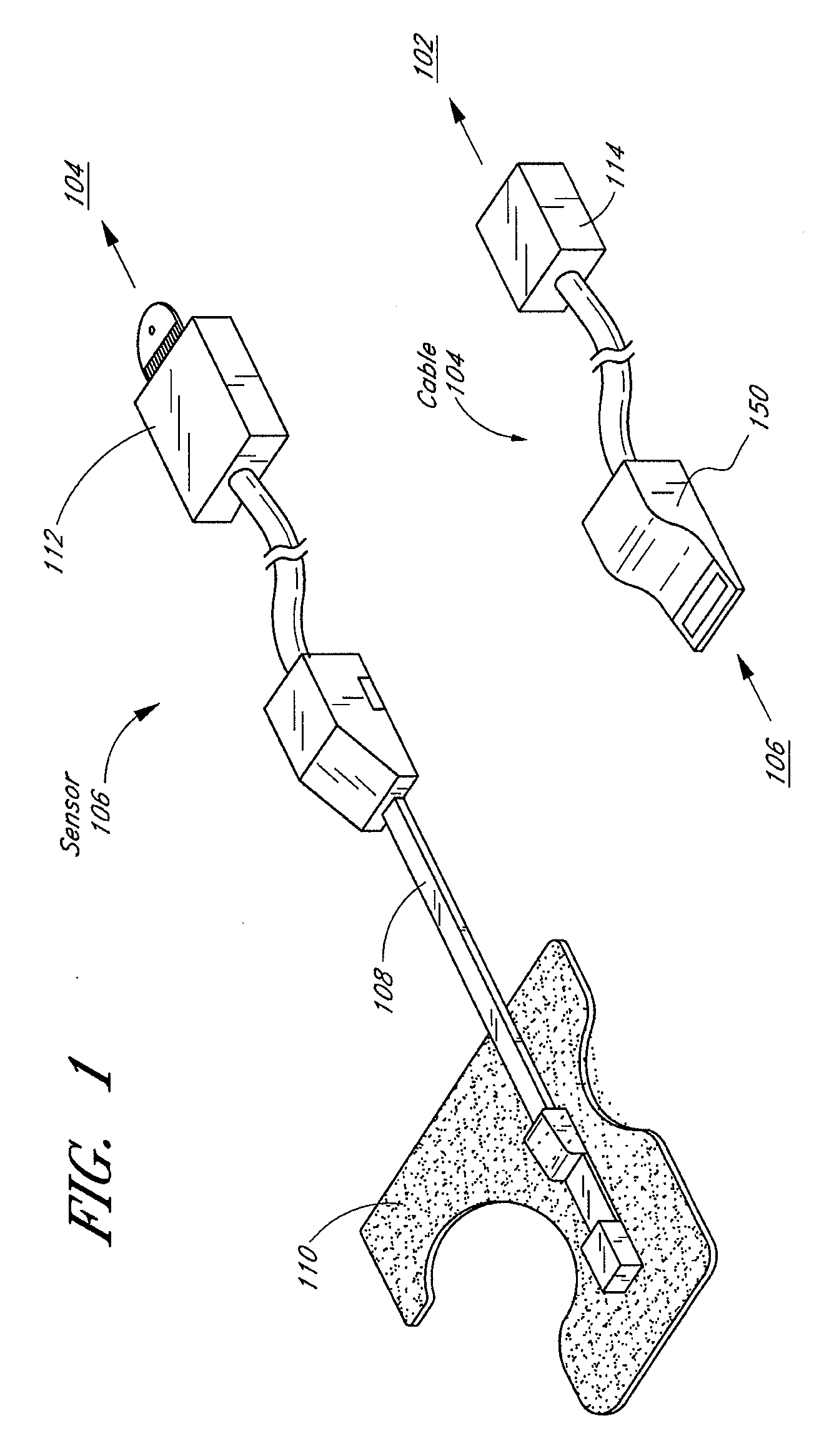

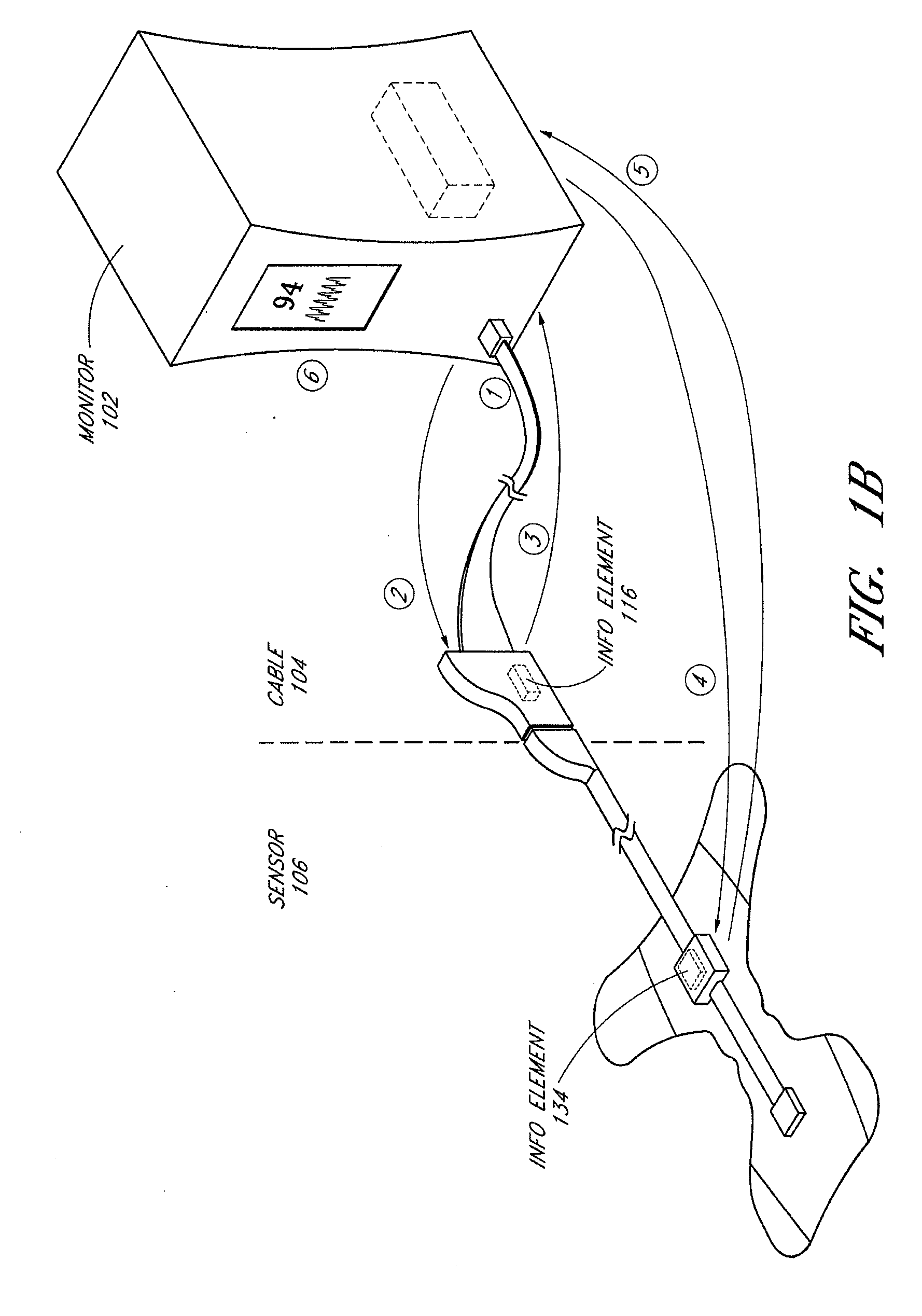

A system and method to help maintain quality control and reduce cannibalization of accessories and attached probes in a highly sensitive patient monitor, such as a pulse oximetry system. One or more attached components may have information elements designed to designate what quality control mechanisms a patient monitor should look to find on that or another component or designate other components with which the one component may properly work. In a further embodiment, such information elements may also include data indicating the appropriate life of the component.

Owner:JPMORGAN CHASE BANK NA

Patient monitor capable of monitoring the quality of attached probes and accessories

ActiveUS20120319816A1Reduce capacityReduce the possibilityProgramme controlElectric signal transmission systemsQuality controlPulse oximetry

A system and method to help maintain quality control and reduce cannibalization of accessories and attached probes in a highly sensitive patient monitor, such as a pulse oximetry system. One or more attached components may have information elements designed to designate what quality control mechanisms a patient monitor should look to find on that or another component or designate other components with which the one component may properly work. In a further embodiment, such information elements may also include data indicating the appropriate life of the component.

Owner:JPMORGAN CHASE BANK NA

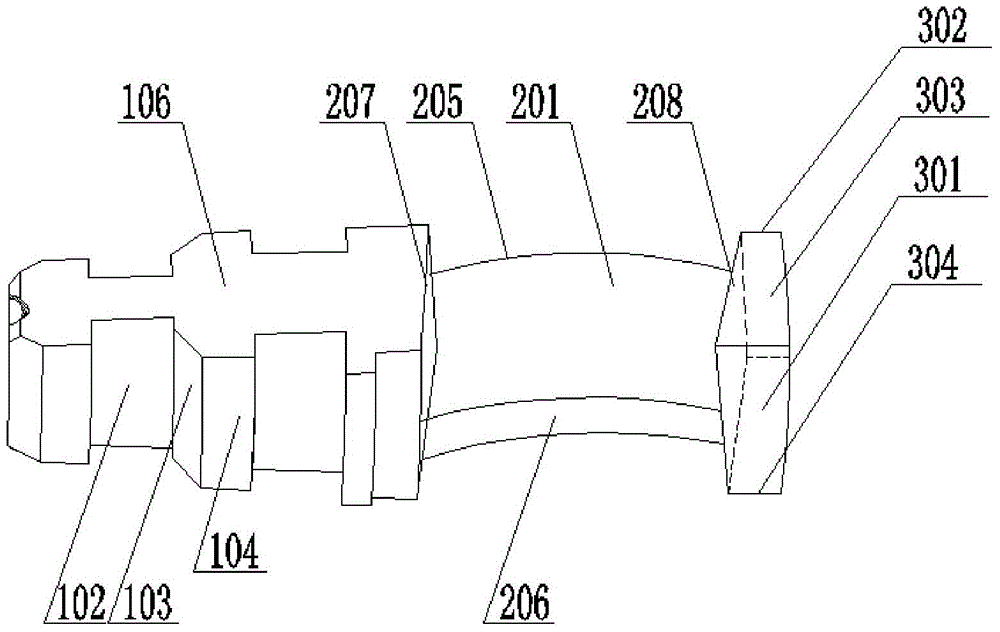

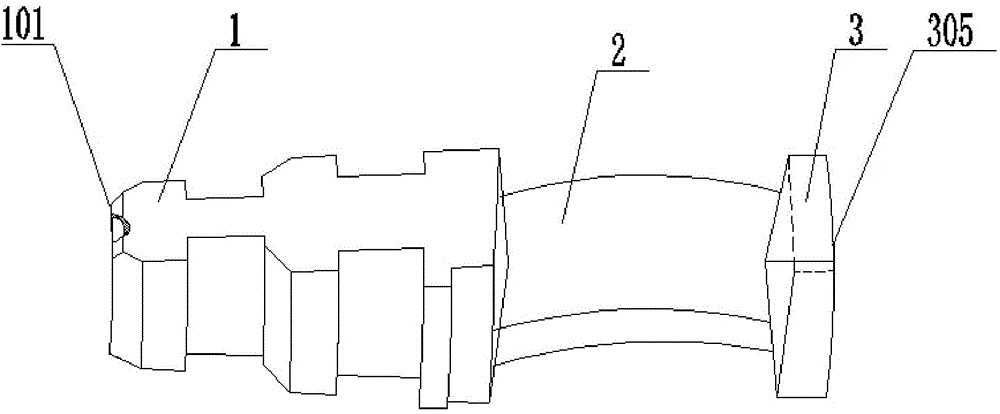

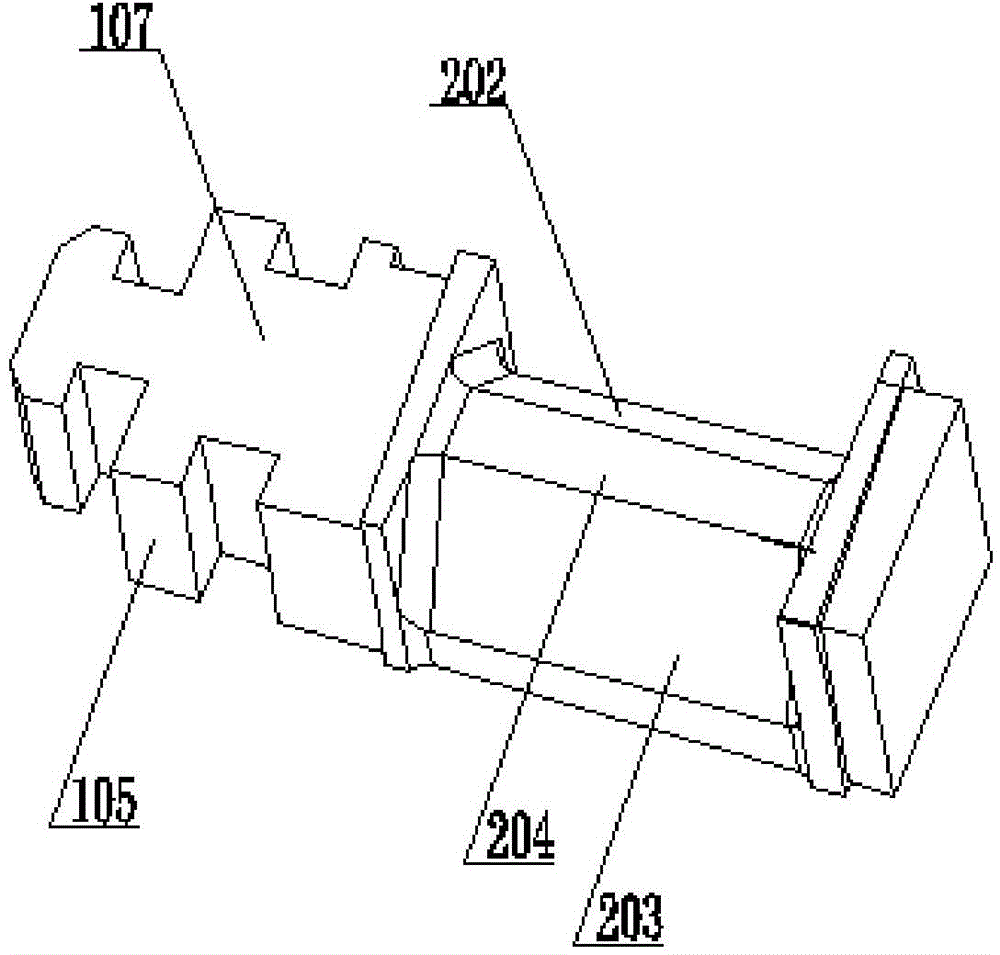

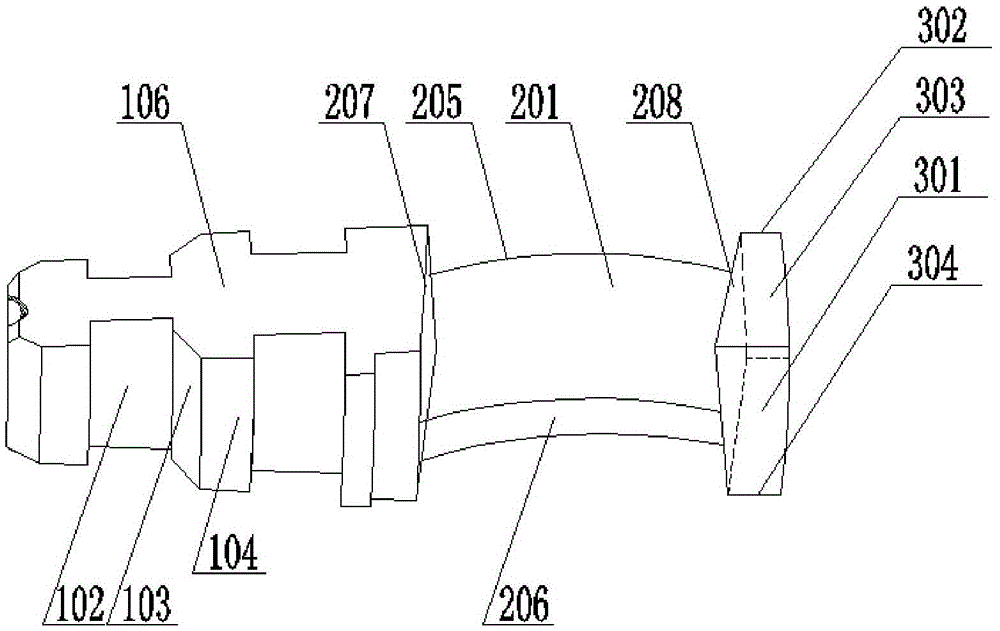

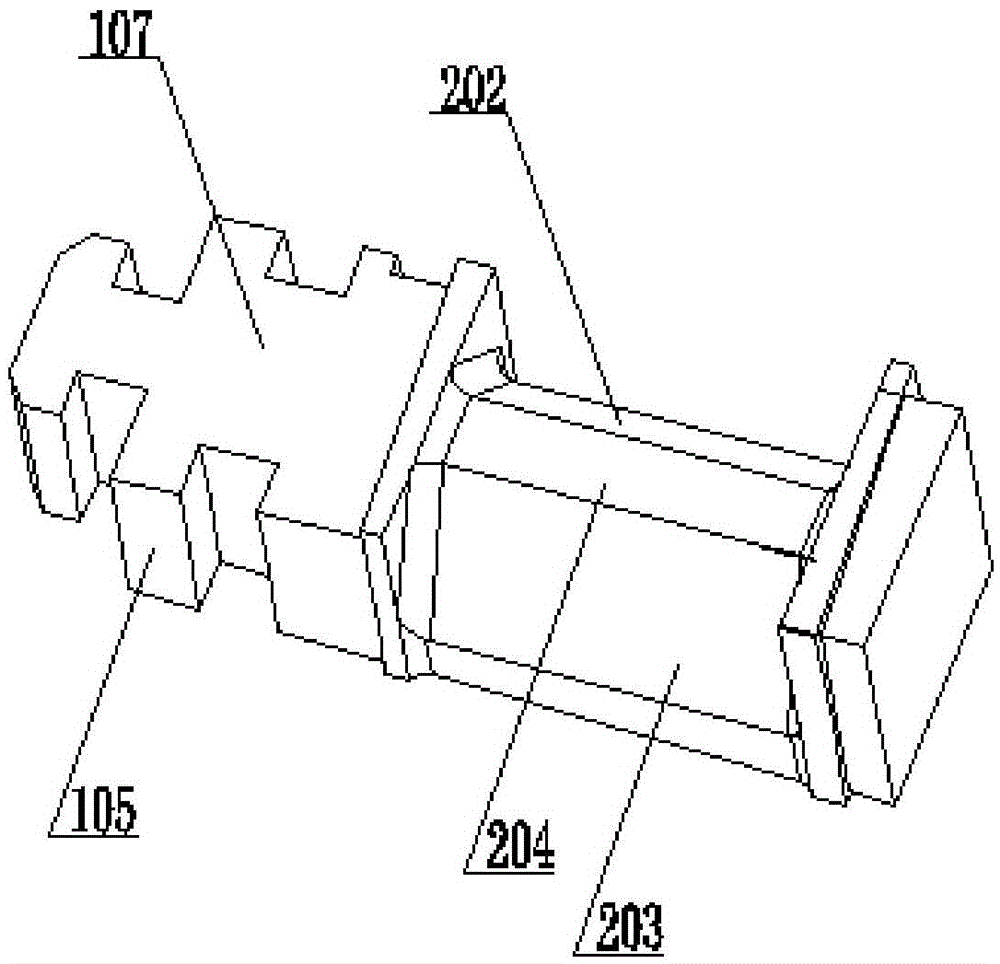

Machining process of axial-flow type turbine blade

The invention discloses a machining process of an axial-flow type turbine blade. The machining process of the axial-flow type turbine blade comprises the following steps that two side faces are machined on a square blank stock through an end face end mill on an ordinary milling machine through two process of rough milling and finish milling, another two side faces are machined with the two machined side faces as base planes, and then the two end faces are machined through the end face end mill; a steam outlet side face is machined on one side face through two process of rough milling and finish milling, the position, close to the steam outlet side face, of the blade root end face is marked as C, a face which forms an acute angle with the steam outlet side face and is adjacent to the steam outlet side face is marked as N and is the inner radial surface, and the other three side faces are machined to be a parallelogram through rough milling and finish milling; central holes are drilled in the blade root end face and the blade crown end face; the blade type is roughly milled through the end face end mill, the blade root is roughly milled, and finally the blade crown is roughly milled; then the blade is installed on a five-axis numerical control machining center for alignment and is machined in a finish mode; a process head at the blade root end face is roughly sawn through a sawing machine; the turbine blade is detected according to the requirements of a drawing.

Owner:南京赛达科技有限公司

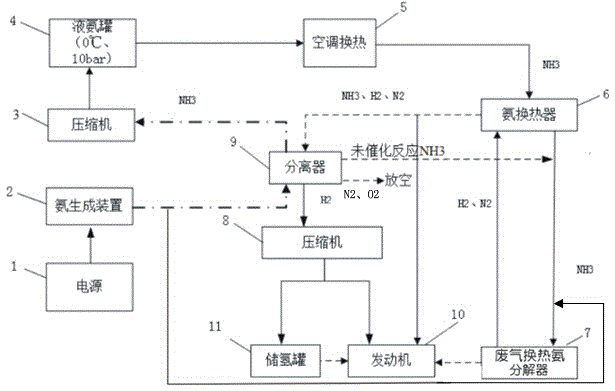

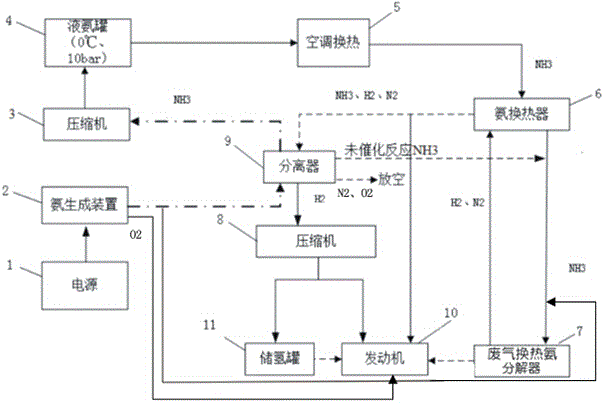

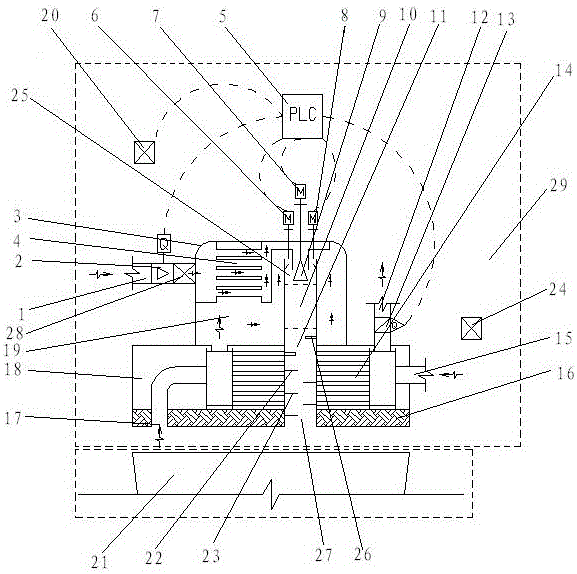

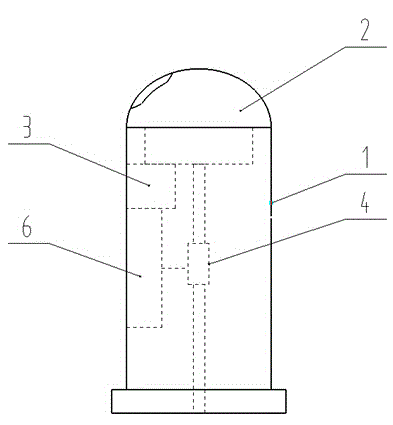

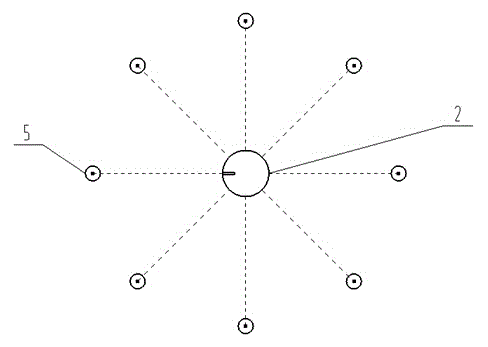

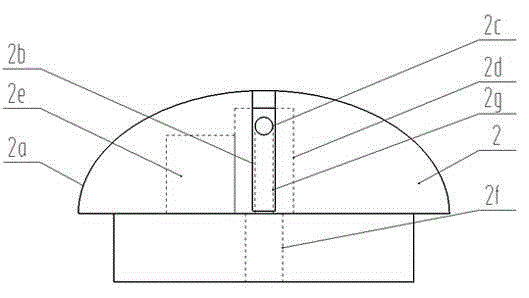

Novel automobile engine hydrogen and ammonia blended fuel supply device

ActiveCN104675580AImprove thermal energy utilization efficiencyEliminate emissionsInternal combustion piston enginesNon-fuel substance addition to fuelParticulatesEnvironmental resistance

The invention provides a novel automobile engine hydrogen and ammonia blended fuel supply device, which comprises an ammonia generation device, wherein an external power supply can be used for storing ammonia prepared from electrolysis into a liquid ammonia tank under a general condition of parking; hydrogen produced from ammonia decomposition can also be stored in a hydrogen storage tank, and the ammonia and the hydrogen can be jointly used as engine fuel when an engine works. The device can externally be added with ammonia fuel to guarantee fuel supply. The device is characterized in that catalytic decomposition can be carried out by the exhaust gas heat of the engine or with electric energy heating ammonia to effectively improve heat energy use efficiency; the ammonia and the hydrogen are used as the engine fuel to effectively eliminate the emission of greenhouse gases, such as CO2 and the like and substantially lighten pollution on the environment by harmful emissions, such as CO, PM (Particulate Matter) and the like; the overuse of petroleum can be effectively alleviated, and the blended fuel is used for replacing gasoline to serve as the green environmentally-friend fuel of the automobile. According to the device, the ratio of hydrogen and ammonia fuel can be controlled through an automobile electronic control unit (ECU) to improve engine combustion efficiency, and the ignition reliability of the fuel is extremely high.

Owner:王海斌

Manufacturing method of color concrete granite flamed-surface terrace

InactiveCN103556557AMitigate overuseImprove the problem of easy falling offIn situ pavingsArchitectural engineeringExpansion joint

The invention discloses a manufacturing method of a color concrete granite flamed-surface terrace, relates to the technical field of building construction and specifically relates to a manufacturing method of a color concrete terrace. The manufacturing method comprises the following steps: (I), erecting a form; (II), casting concrete; (III), leveling; (IV), throwing a reinforcing agent; (V), finishing; (VI), throwing a granite coloring agent; (VII), throwing a release agent; (VIII), rubbing textures; (IX), cutting an expansion joint, (X), cleaning a surface layer, and (XI), spraying and brushing a sealing agent. The manufacturing method disclosed by the invention solves the problems that existing granite stone is high in manufacturing cost, easy to break, large in loss and short in service life. Moreover, a series of environment-friendly problems that stone energy resources are exploited, a geological environment is affected, energy resources are exhausted, ecological damage is caused can be effectively relieved.

Owner:王建国

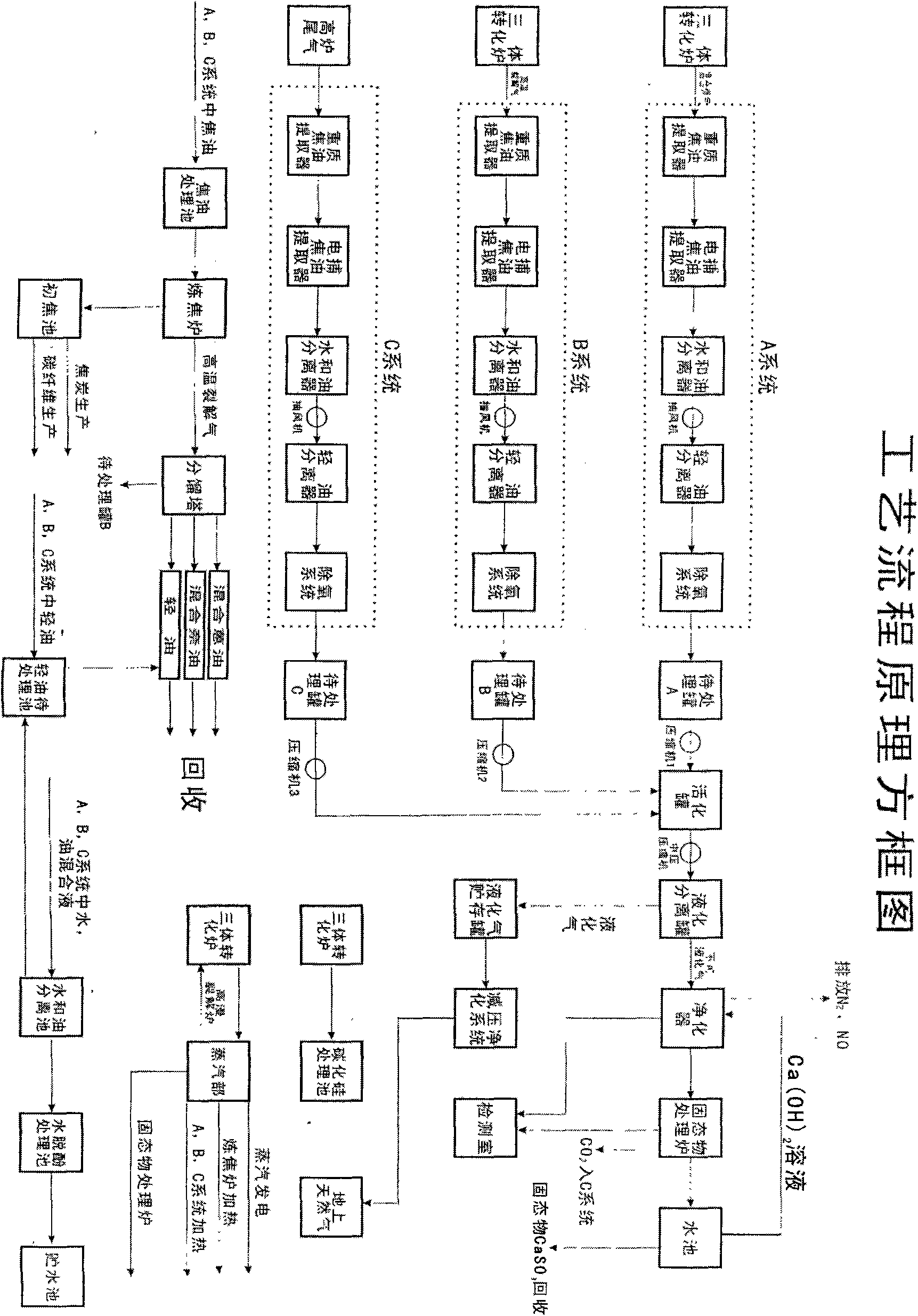

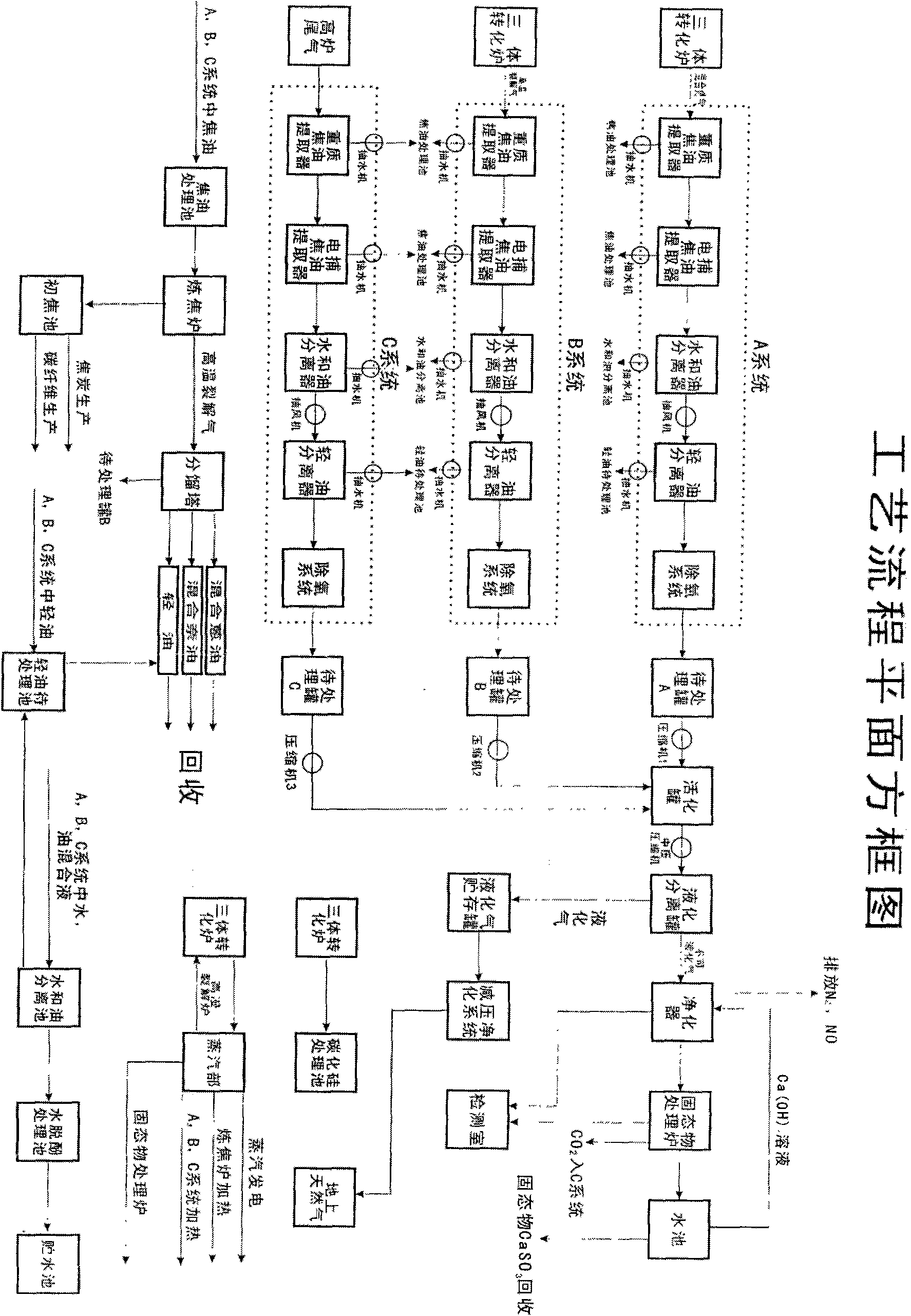

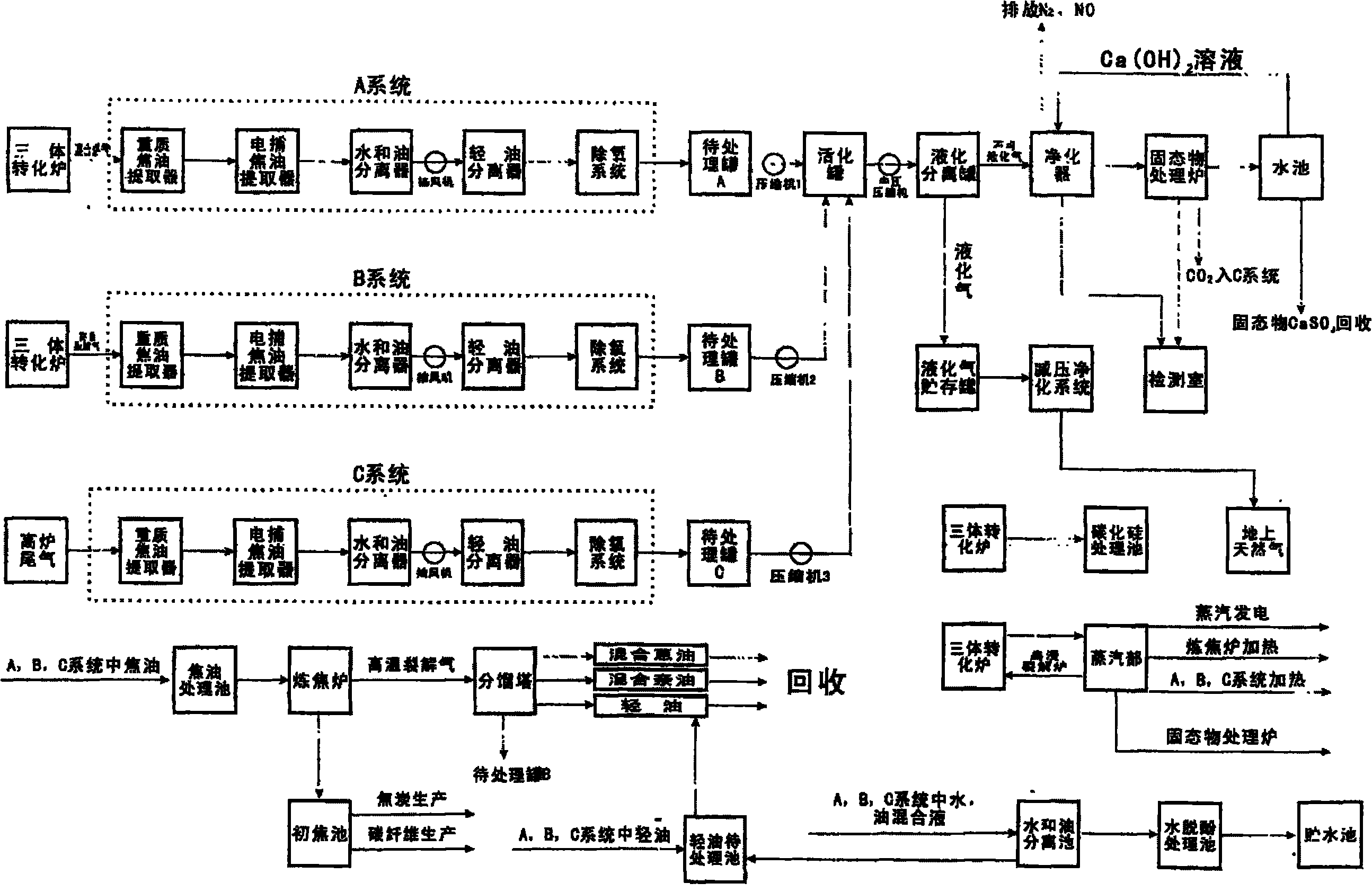

Technique for producing new energy by using firewood, grass and straws to treat CO2 in blast furnace tail gas

InactiveCN101948700ARelieve stressRelieve pressureCombustible gas chemical modificationMethane captureNew energyBiological activation

The invention discloses a technique for producing new energy by using firewood, grass and straws to treat CO2 in blast furnace tail gas. The technique comprises the following steps of: scientifically treating the firewood, the grass and the straws to obtain mixed gas, filling the tail gas into treatment tanks A and B for later use after the mixed gas is treated by A and B treatment systems respectively, reclaiming all the blast furnace tail gas through a C treatment system and filling the tail gas into a treatment tank C, then conveying the gas in the treatment tanks A, B and C to an activation tank with compressing respectively, compressing the activated gas to form liquefied gas and non-liquefied gas, directly charging the liquefied gas for users, treating and reclaiming the non-liquefied gas, and discharging the pollution-free gas to the atmosphere. The whole production system does not consume the conventional energy; the pollution emission is zero; ground natural gas, liquefied gas, mixed anthracene oil, mixed naphthalene oil, light oil, steam generated power and the like are produced at the same time; the economic and social benefits are very good; and the energy conservation and emission reduction effects are very obvious.

Owner:伍思宇

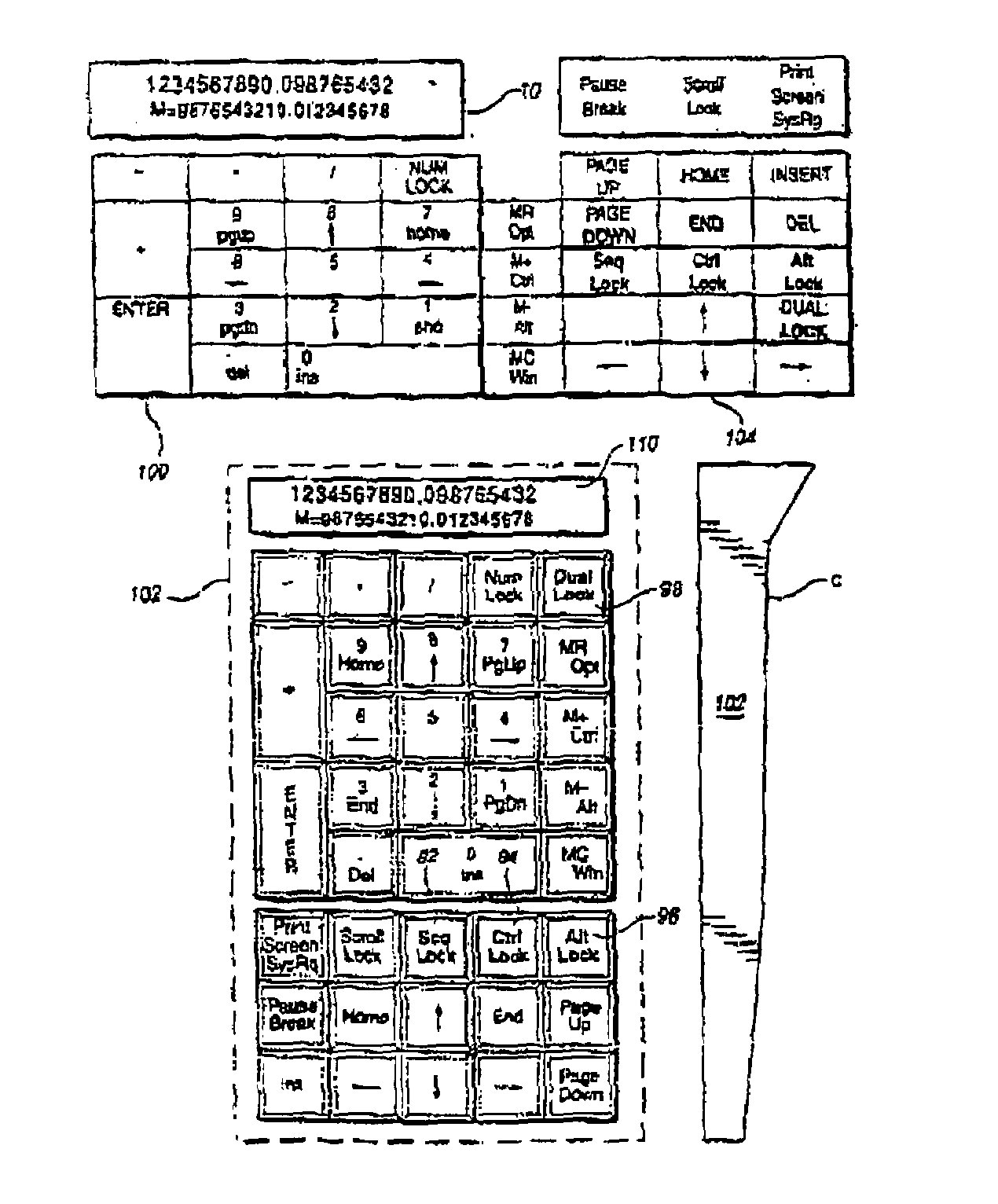

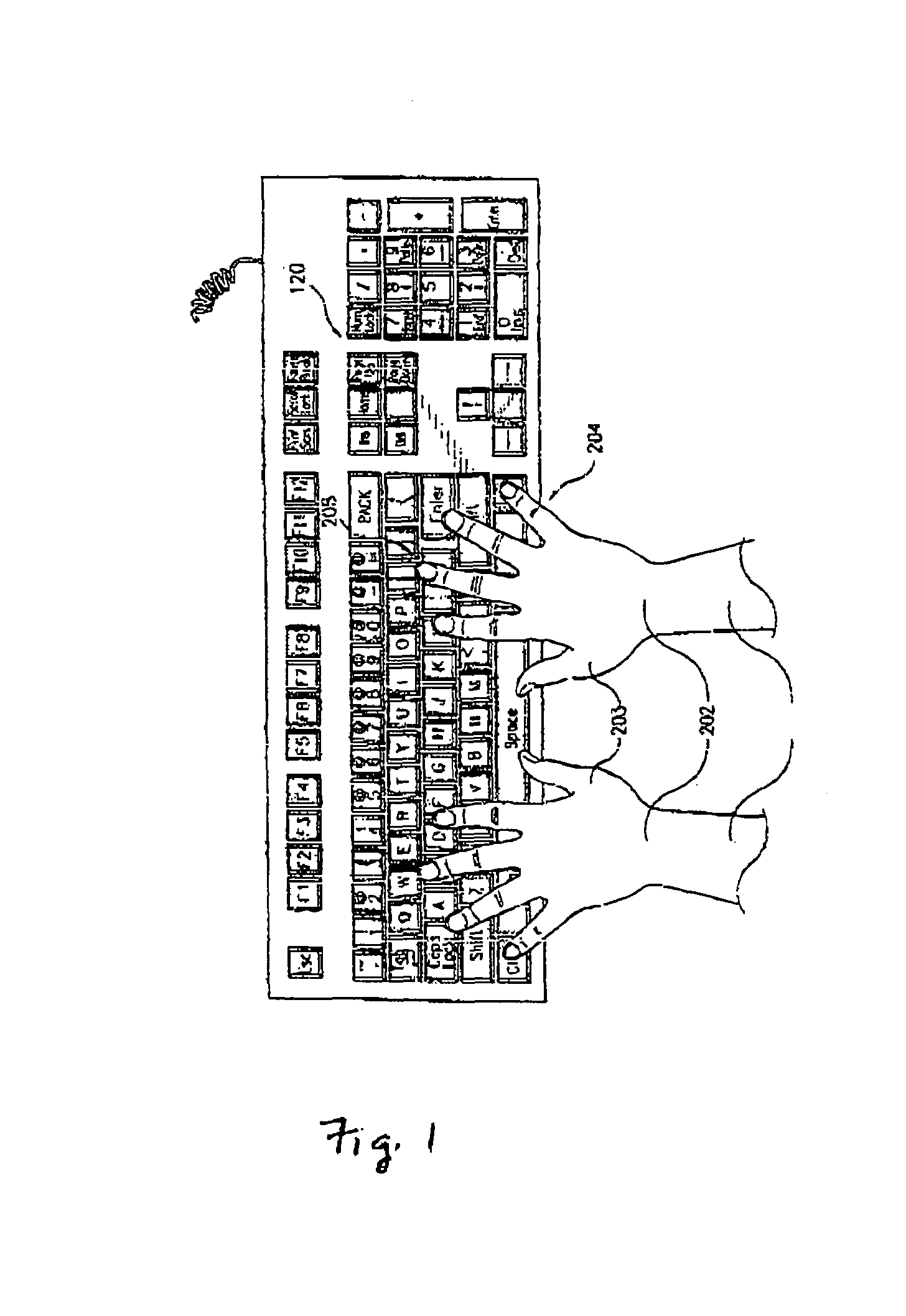

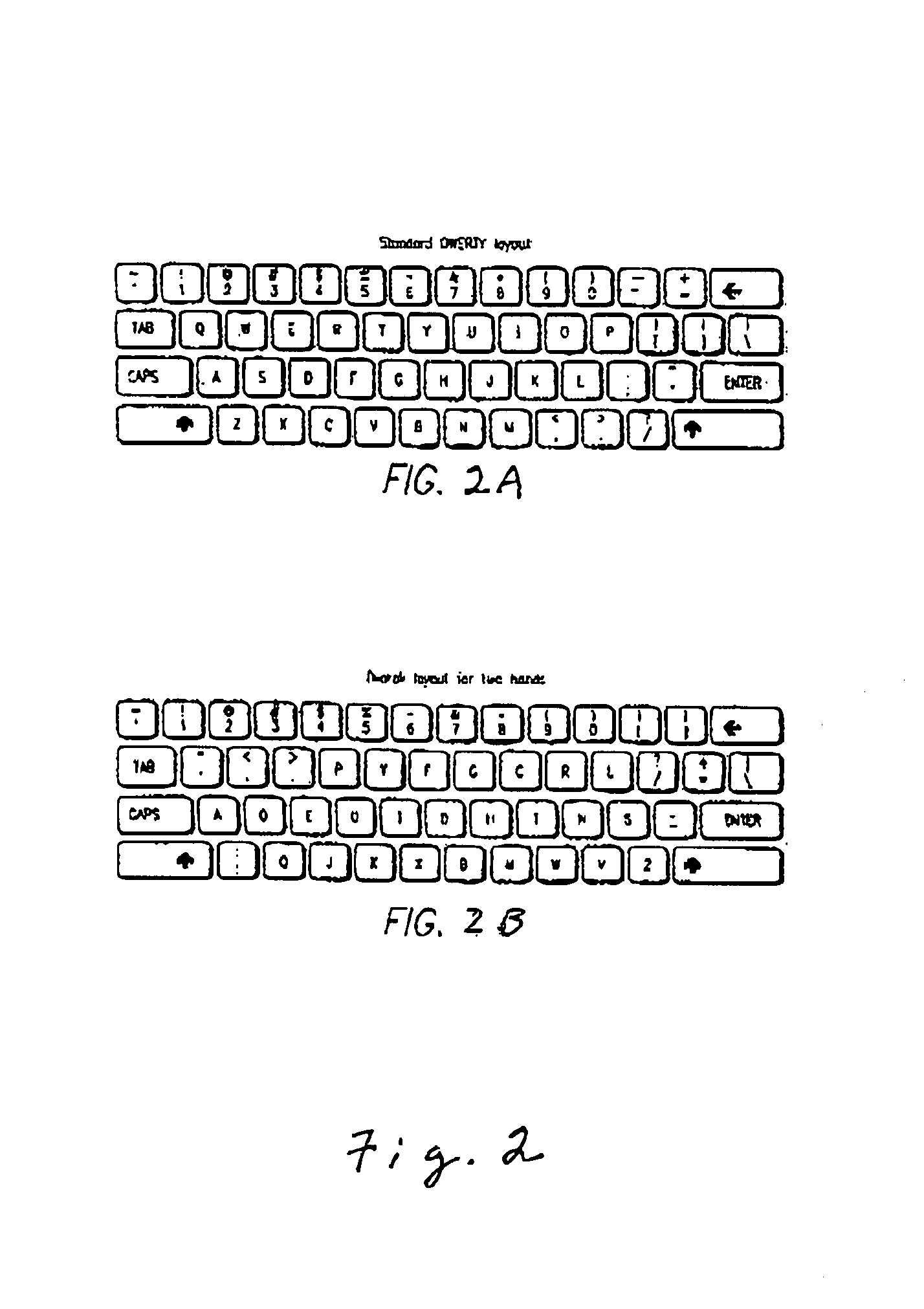

Dual numerical keyboard based on dominance

InactiveUS7255503B2Reduce overuseShorten entry timeInput/output for user-computer interactionElectronic switchingComputer usersCTS - Carpal tunnel syndrome

There is a need to develop a more sophisticated educational system of keyboard set ups for not only the disabled population from their worker's compensation injuries but for the entire continuum of keyboard, keypad and mouse users nationally and internationally for the prevention of computer related injuries. Due to the rising medical costs associated with upper extremity sprains and strains and more importantly, carpal tunnel syndrome, design companies are making ergonomic changes in the mouse, keyboard design. However, these changes are being made without regard for the user's dominance. Now a long term solution has been invented based on two simple tests by noted researchers. The dual system of keyboard / keypad, mouse or calculator input device selection based on the computer users human factors of dominance will have a decided impact on the reduction of computer related work force injuries or for other people with disabilities.

Owner:GRAFTON CHARLENE H

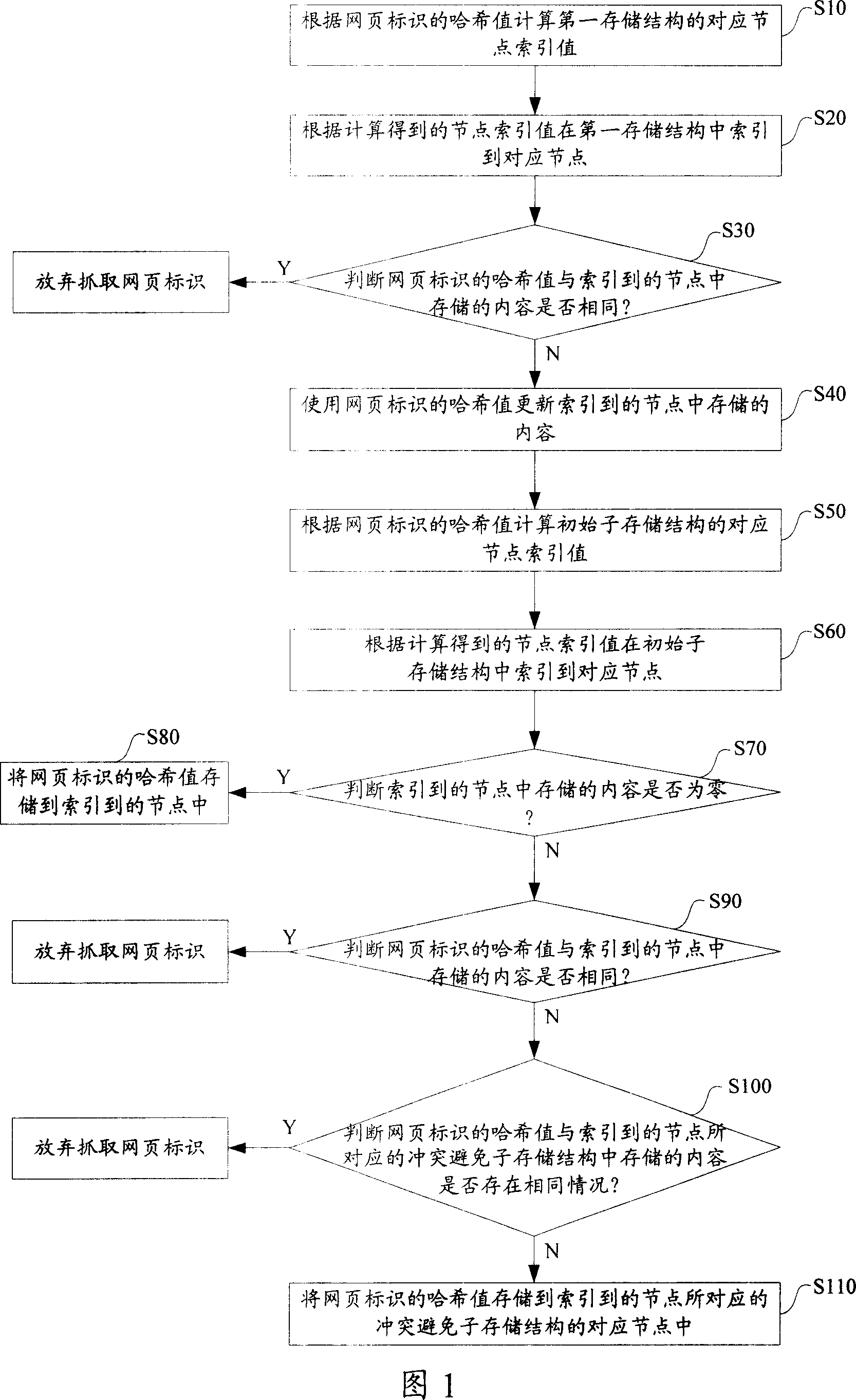

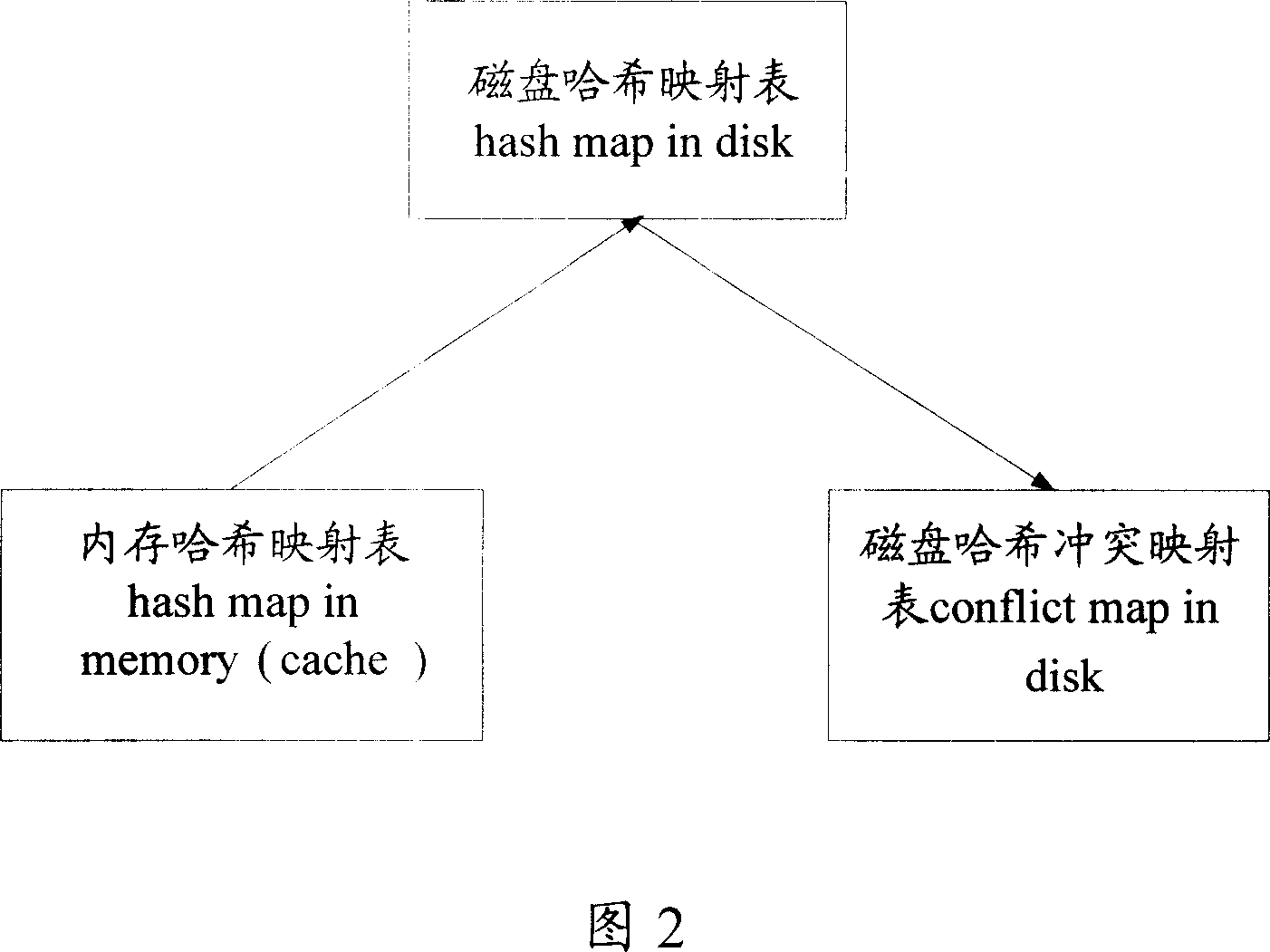

Webpage mark extracting method

ActiveCN1991830AReduce in quantityHigh speedSpecial data processing applicationsWeb pageOperating system

Owner:TENCENT TECH (SHENZHEN) CO LTD

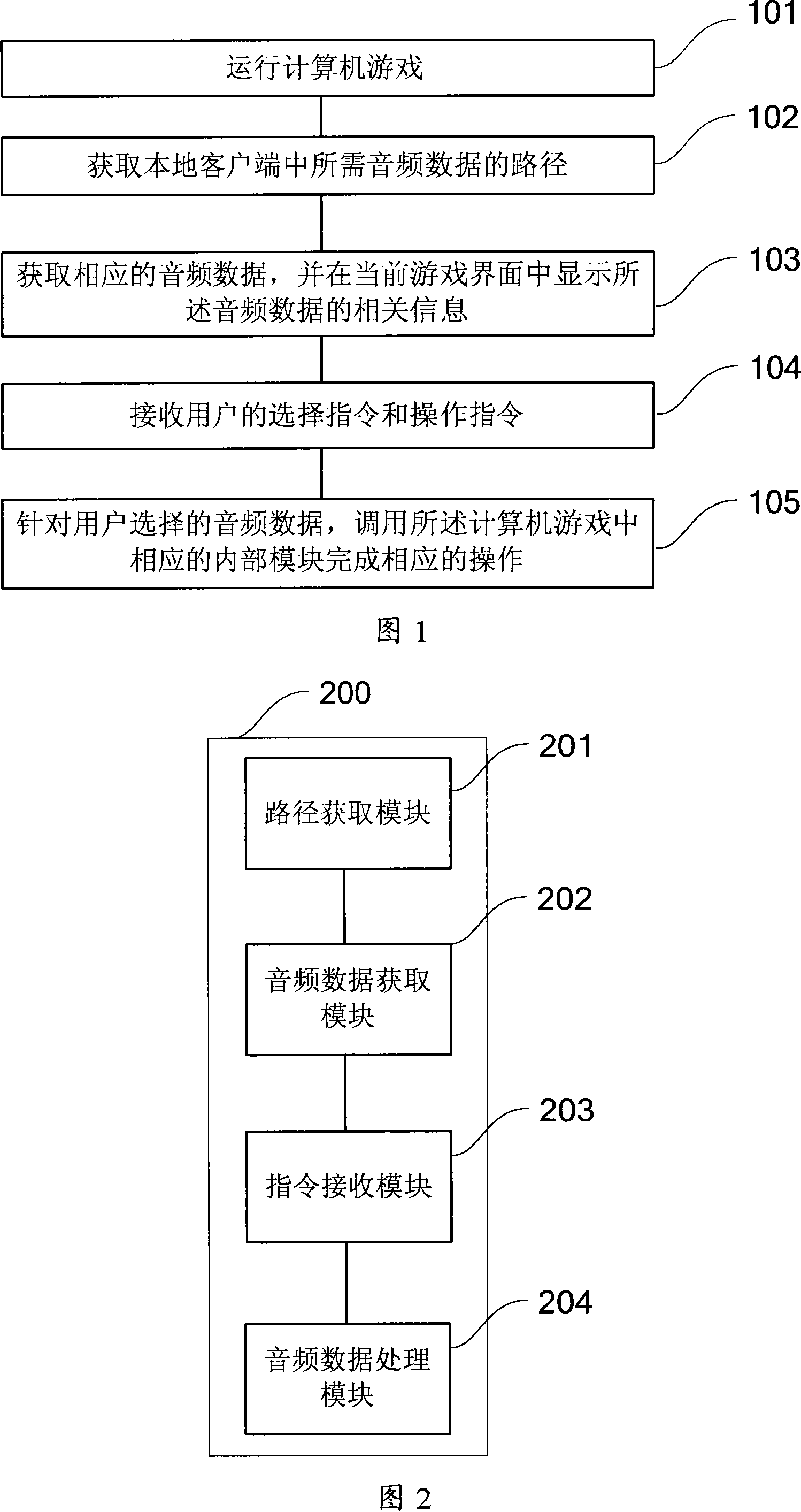

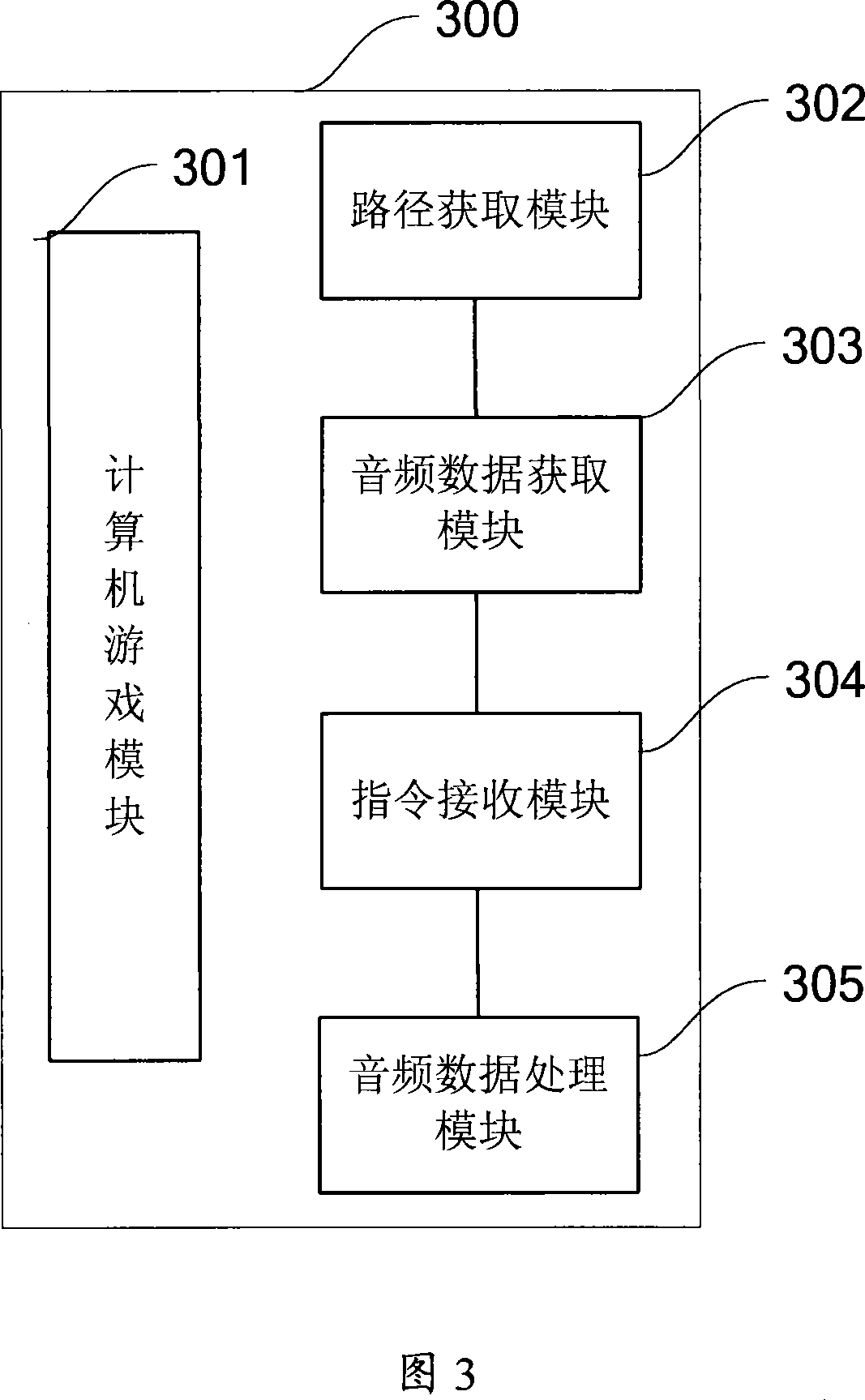

Method and system for processing audio data in computer game

ActiveCN101105823ASave resourcesAchieve sharingTransmissionSpecial data processing applicationsRelevant informationData source

The invention provides a method and a system for processing audio data in computer games. The method includes: run computer games; obtain the route of audio data needed by the local client end; obtain the corresponding audio data and display related information of audio data on the current game interface; receive users' selection command and operation command; and mobilize the corresponding internal module in the computer game to complete the corresponding operation according to the audio data selected. The invention innovatively combines audio data of the local client end and audio processing programs of computer games, treating the former as a data source of the later to make it unnecessary to start another application program, thus saving system resources; in addition, the invention also provides the corresponding management operation module for the convenience of managing and operating audio data in the local client end at the internal of games by users.

Owner:BEIJING KINGSOFT SOFTWARE +1

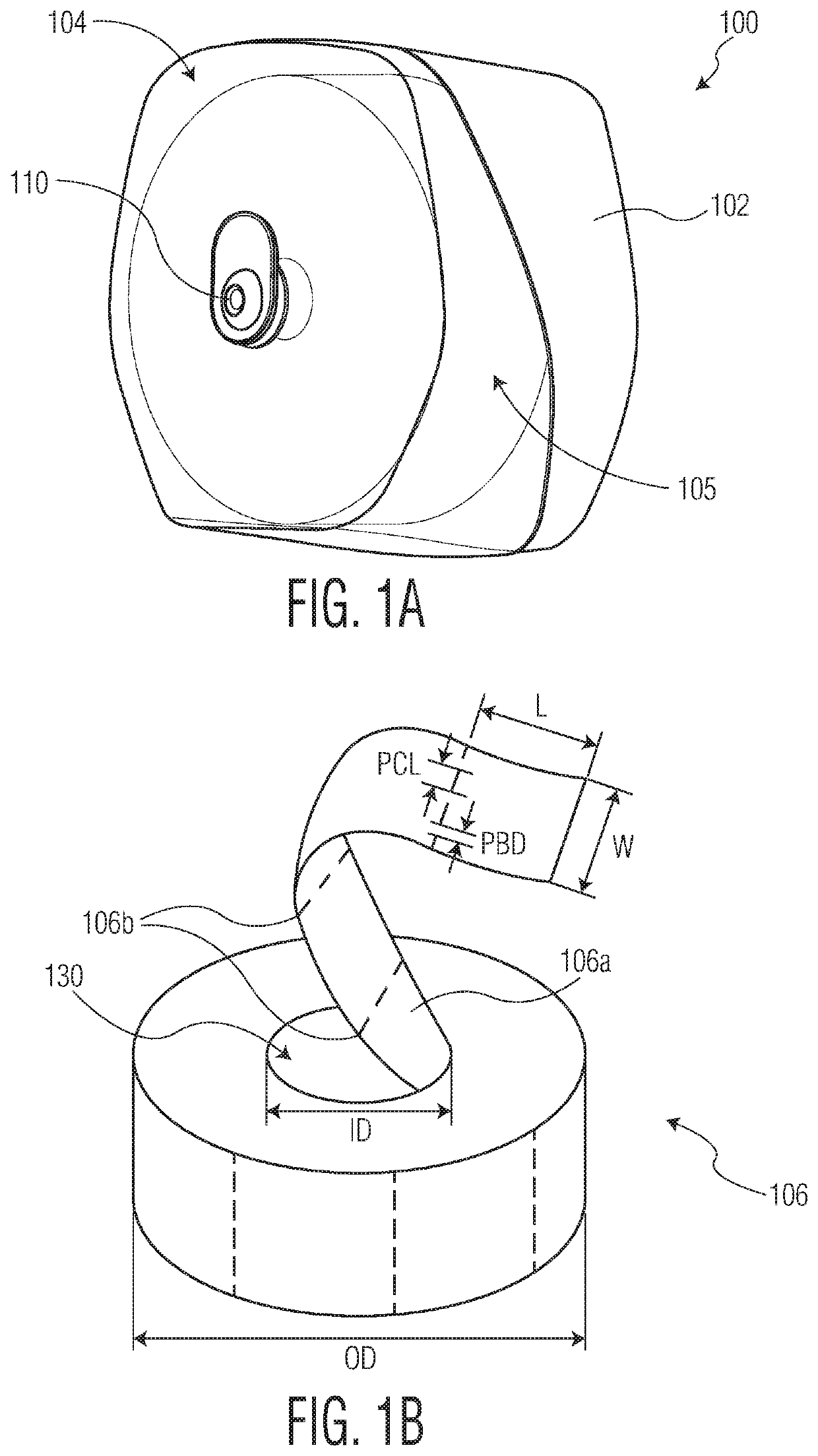

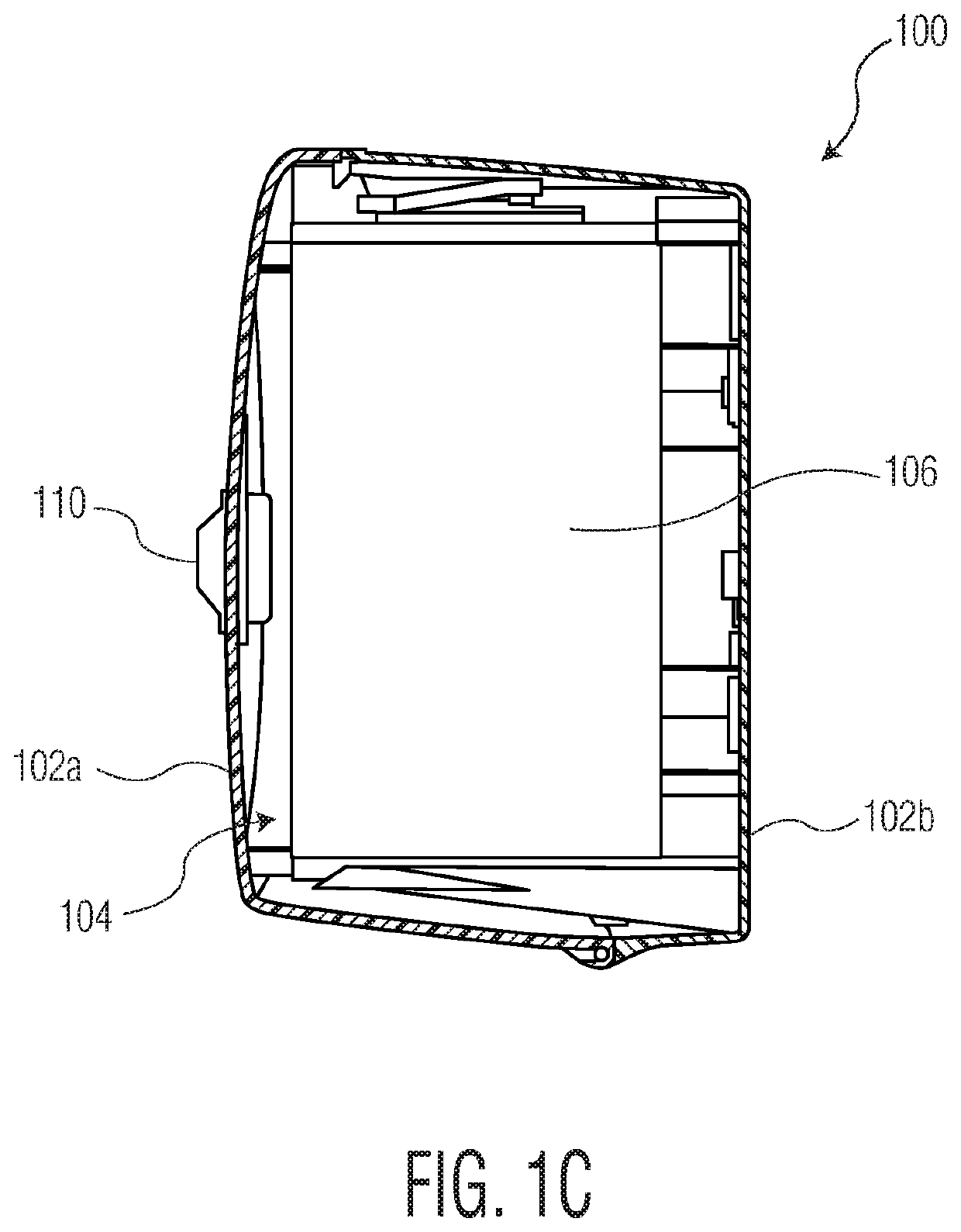

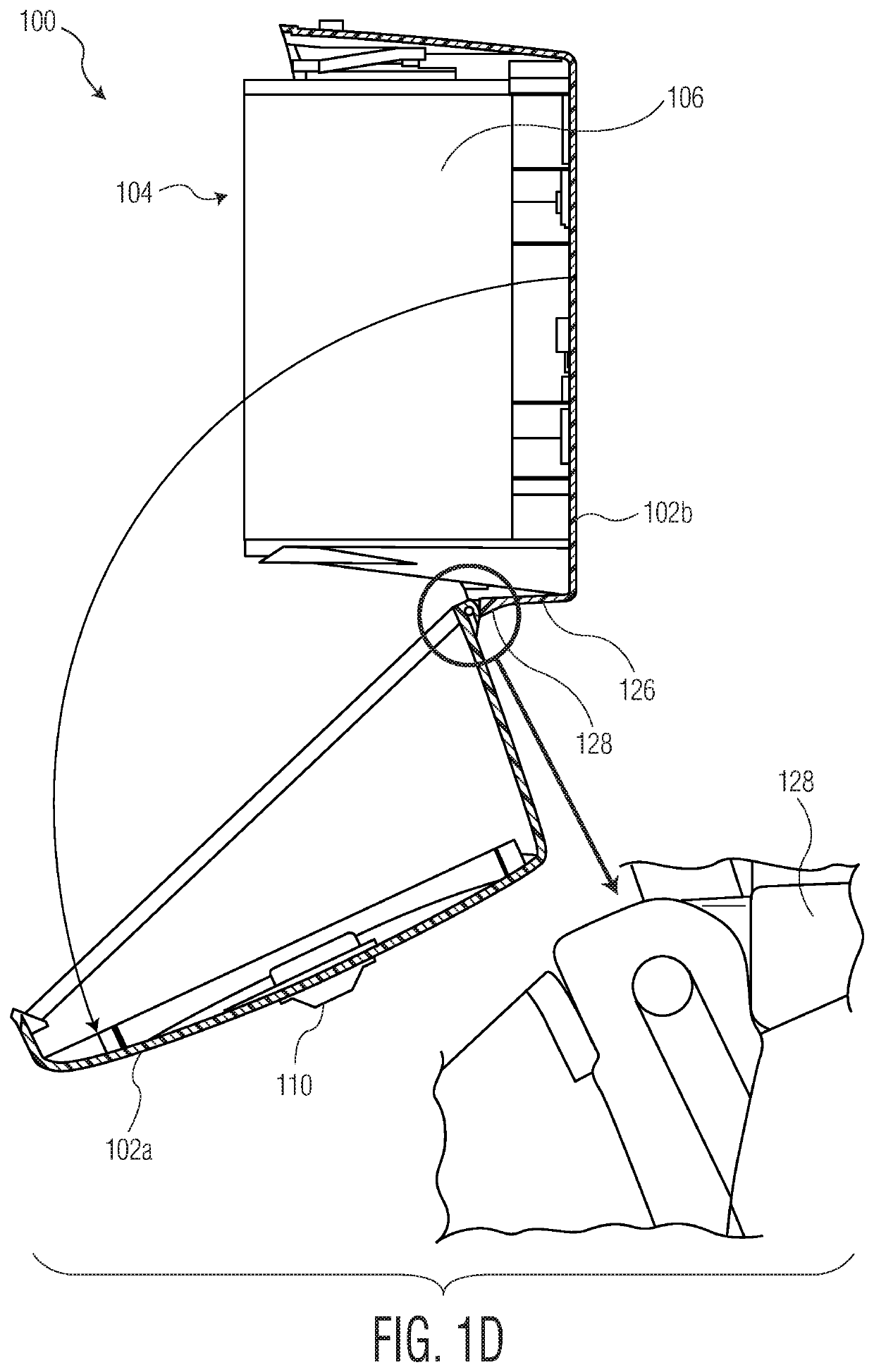

Sheet product dispenser

ActiveUS11172794B2Unnecessary maintenanceUnnecessary service visitDomestic applicationsRolling paperIndustrial engineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for extracting perilla oil and ursolic acid from perilla seeds

InactiveCN105732762ATake advantage ofReduce manufacturing costFatty-oils/fats refiningSteroidsPerilla oilUrsolic acid

The invention provides a method for extracting perilla oil and ursolic acid from perilla seeds. Petroleum ether leaching, column passing and the like are performed to obtain the ursolic acid and oleanolic acid crystals. The method can fully utilize the perilla to obtain the perilla seed oil, ursolic acid and oleanolic acid products, thereby effectively lowering the production cost and fully utilizing the two main active ingredients in the perilla seeds. By combining the resin and crystalline phase, the overuse of the chemical reagents is reduced, thereby ensuring the nature of the product; and thus, the produce can be supplied to food, cosmetics, pharmacy and other industries safely.

Owner:王婧

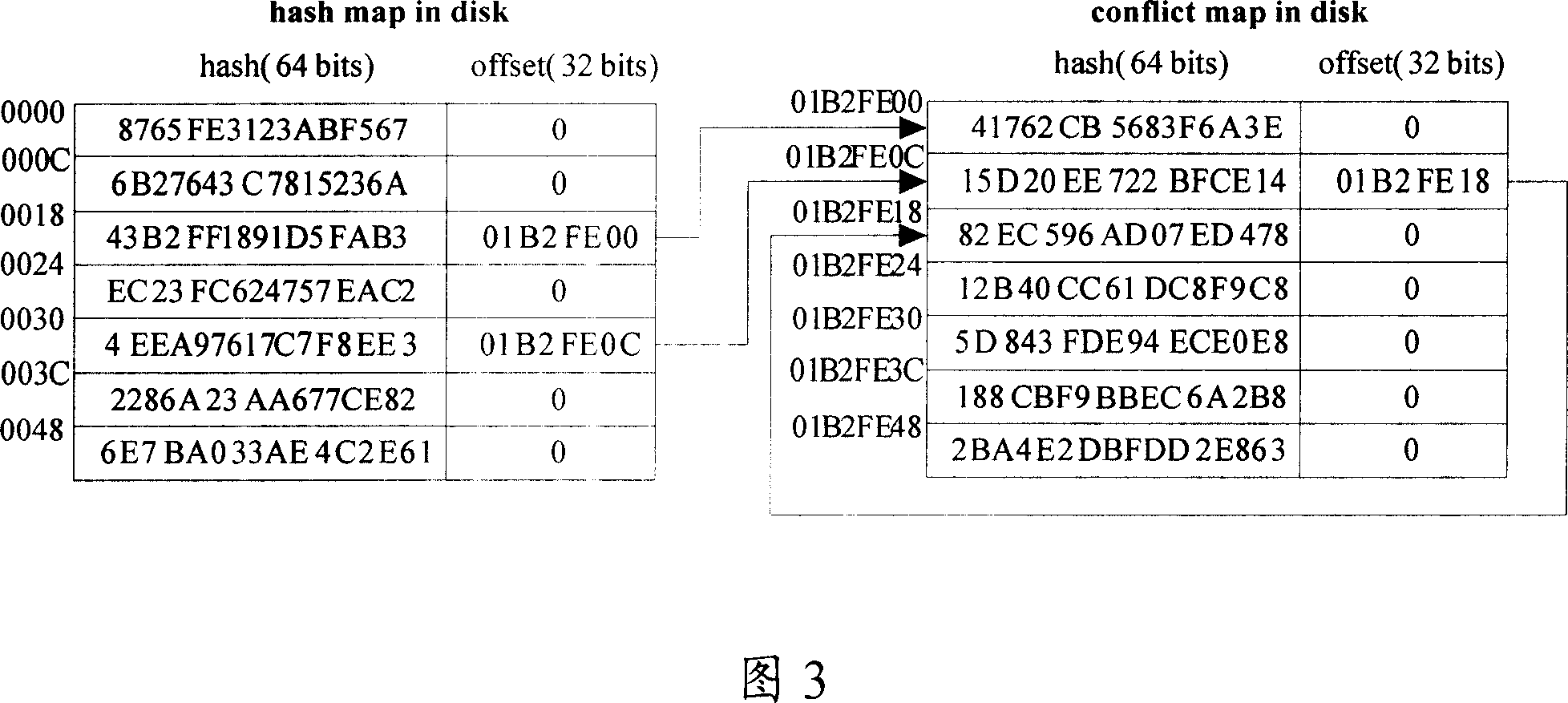

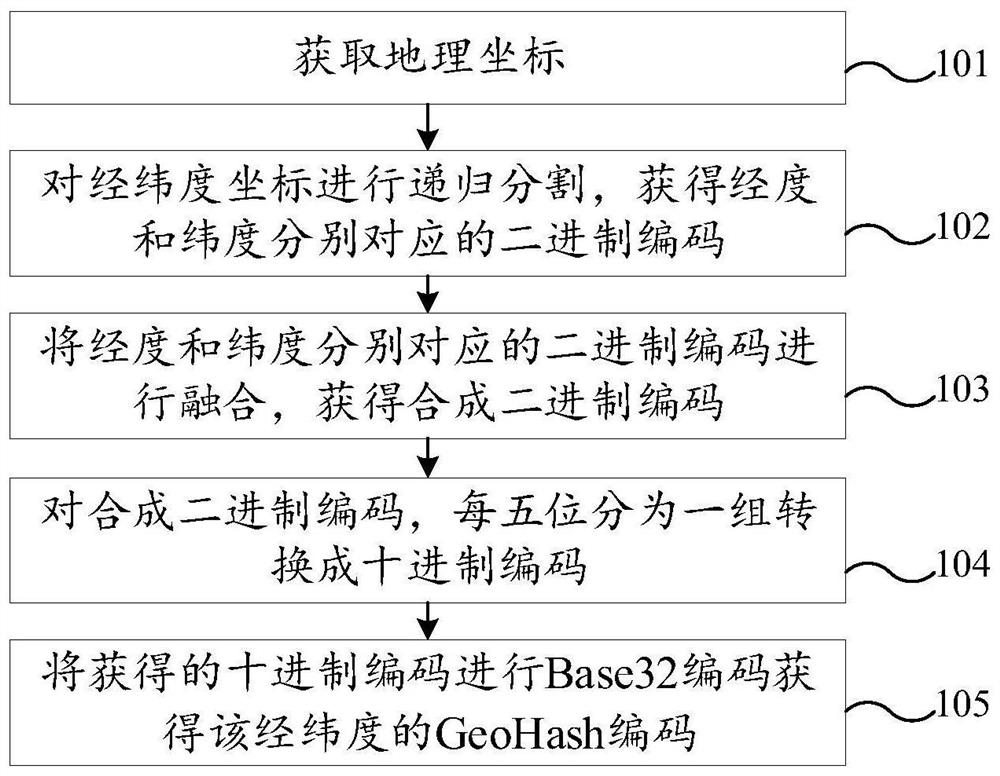

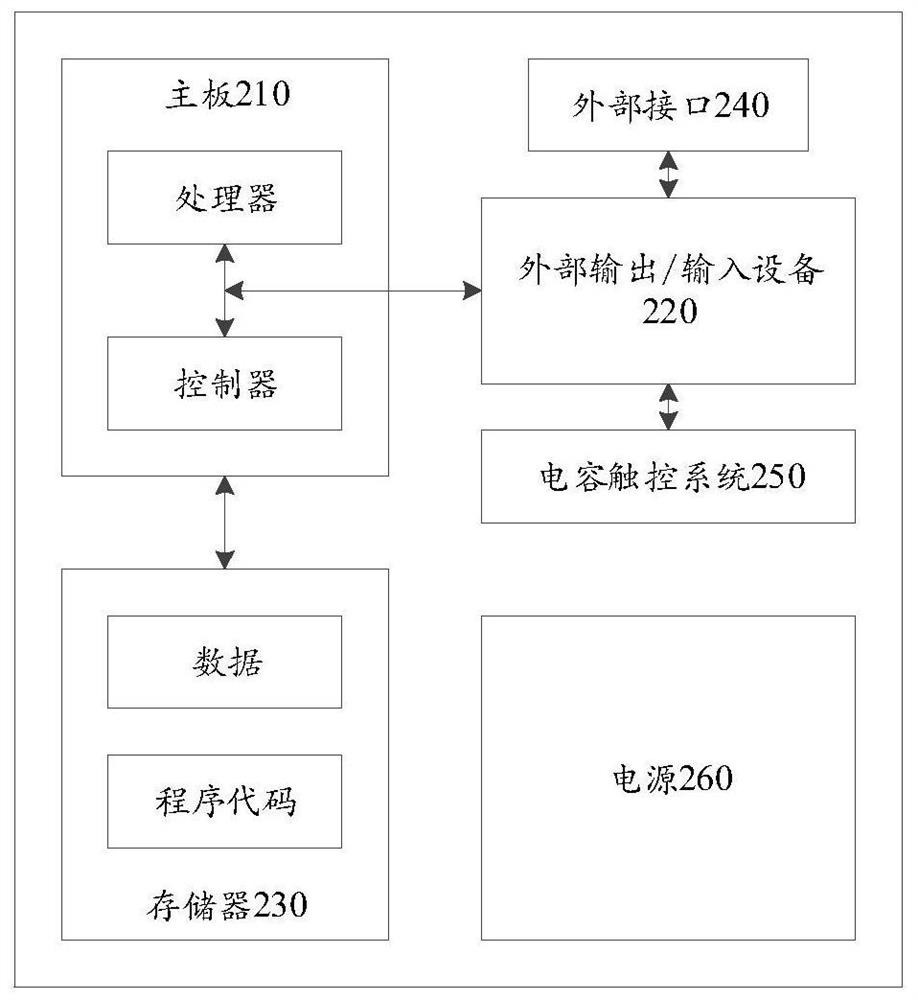

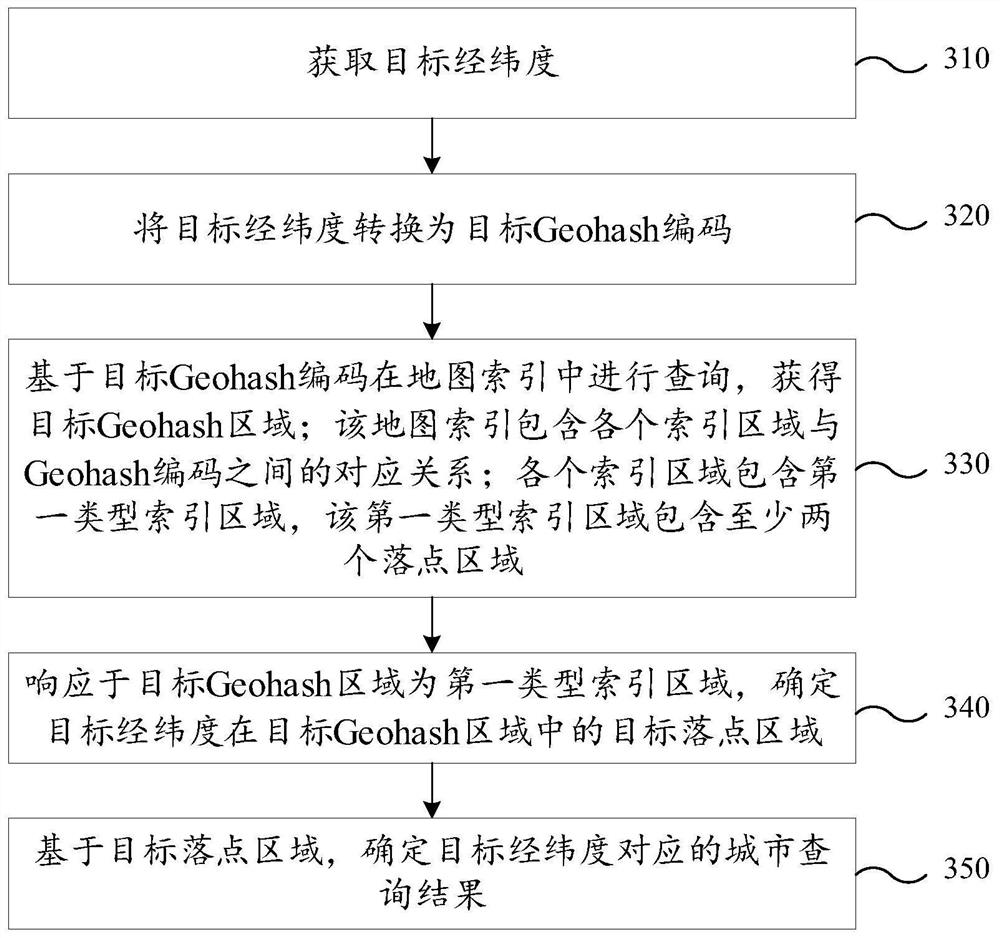

Urban query method, device and equipment based on longitude and latitude and storage medium

PendingCN112486987ASmall amount of calculationImprove search capabilitiesGeographical information databasesSpecial data processing applicationsMeteorologyElectronic map

The invention relates to urban query method, device and equipment based on longitude and latitude and storage medium, and relates to the technical field of electronic maps. The method comprises the following steps: acquiring target longitude and latitude; converting the target longitude and latitude into a target Geohash code; based on the target Geohash code, querying in a map index containing the first type of index region to obtain a target Geohash region; in response to the fact that the target Geohash area is a first type index area, determining a target drop point area of the target longitude and latitude in the target Geohash area; and determining a city query result corresponding to the target longitude and latitude based on the target drop point area. Through the method, in the process of performing city query through longitude and latitude, the calculation amount of the computer equipment is reduced, and the search performance of the computer equipment is improved, so that excessive occupation of calculation resources of the computer equipment due to city query is reduced.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

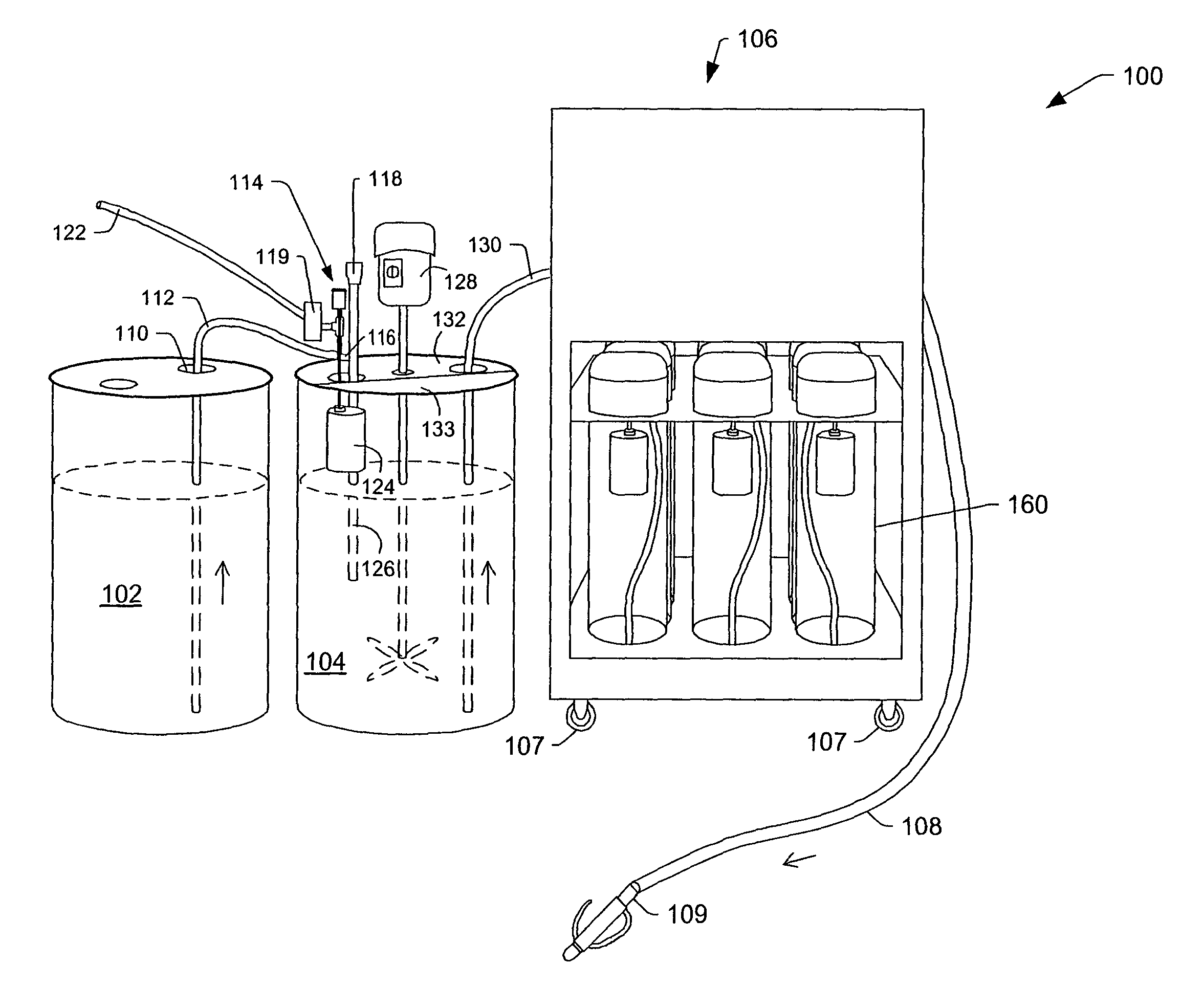

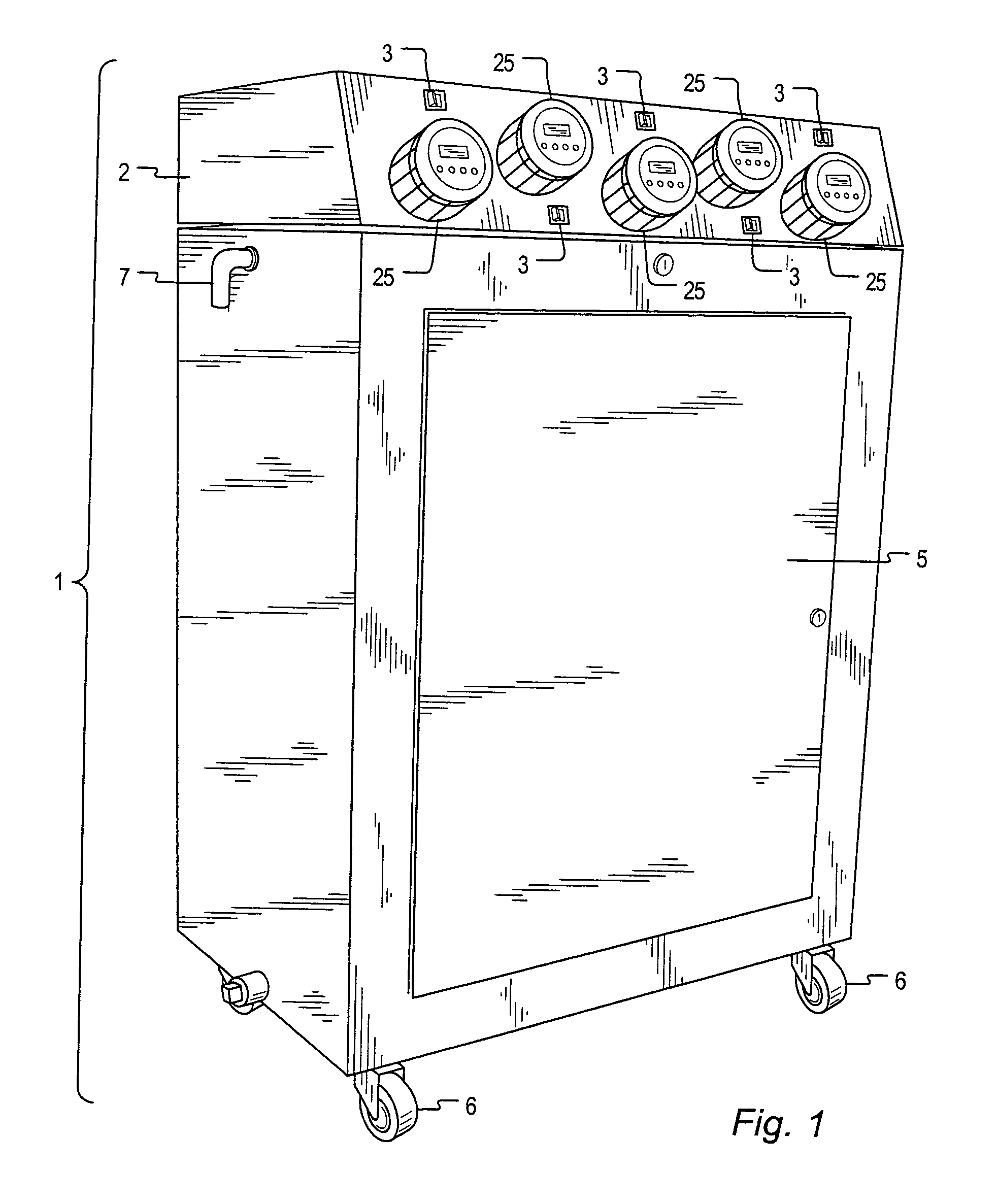

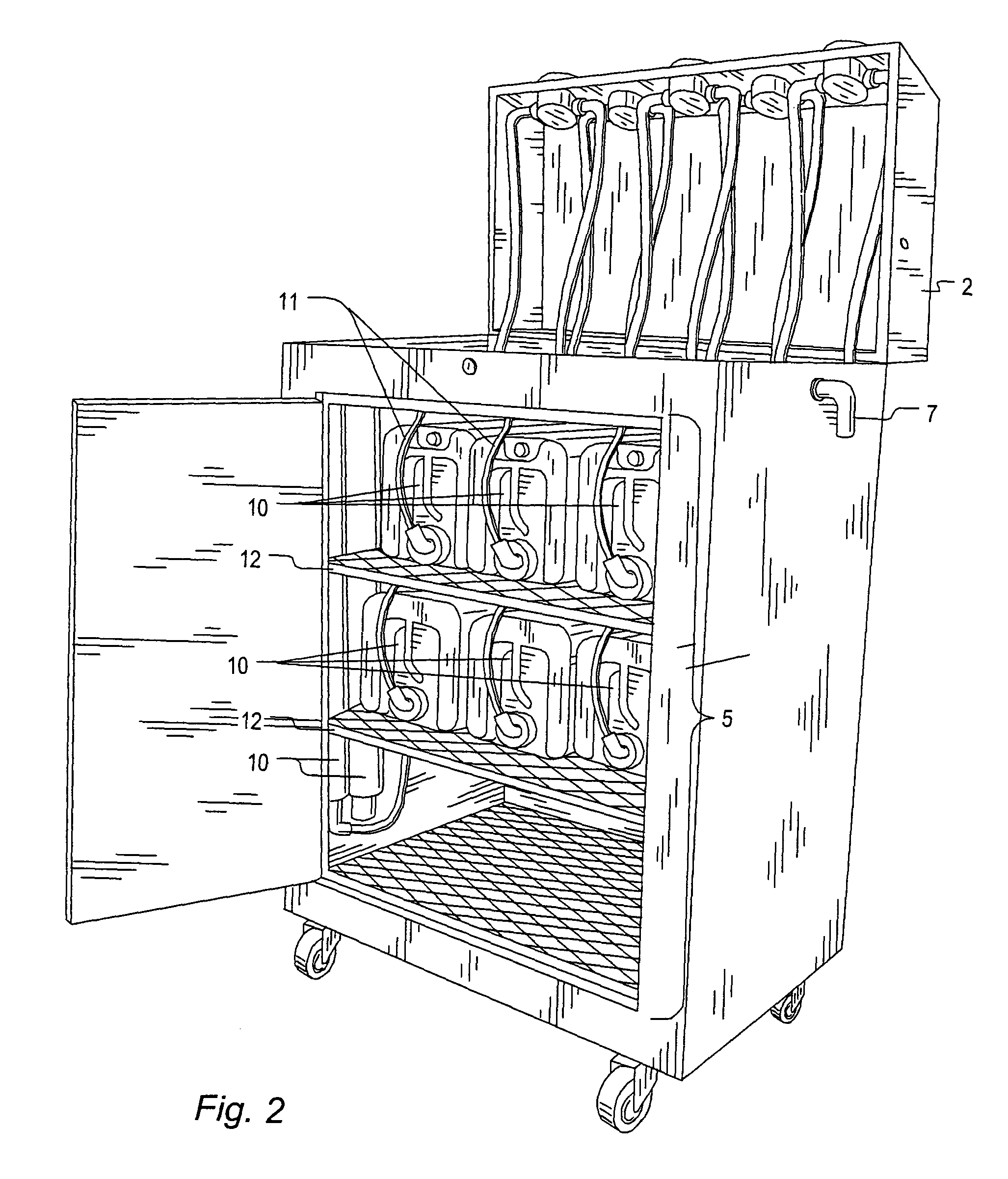

Apparatus and methods for a customer to produce and dispense automobile appearance care products

InactiveUS6988637B2Reduce in quantityReduce overusePower operated devicesFlow mixersProduction logisticsHybrid system

An apparatus may be used to dispense a plurality of automotive appearance care products. The apparatus may include a plurality of storage containers. Mixing systems may be coupled to the storage containers. The mixing systems may combine raw materials with a carrier fluid to produce product fluids. The product fluids may be stored in storage vessels. A plurality of pumps may be used to produce a flow of one or more product fluids. The product fluids may be dispensed through one or more dispensing conduits. A user may dispense the product fluids for use as automotive appearance care products. The user may receive a statement of a fee for using the apparatus based on a selected basis.

Owner:ILLINOIS TOOL WORKS INC

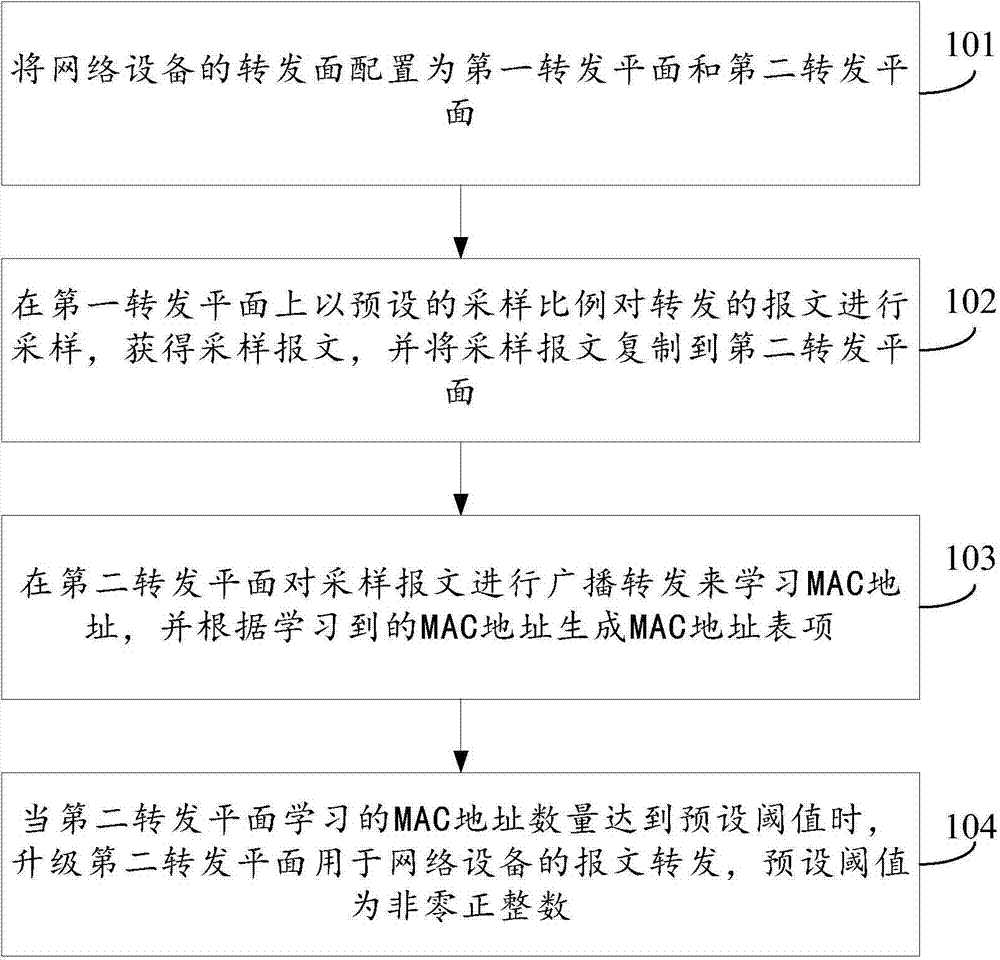

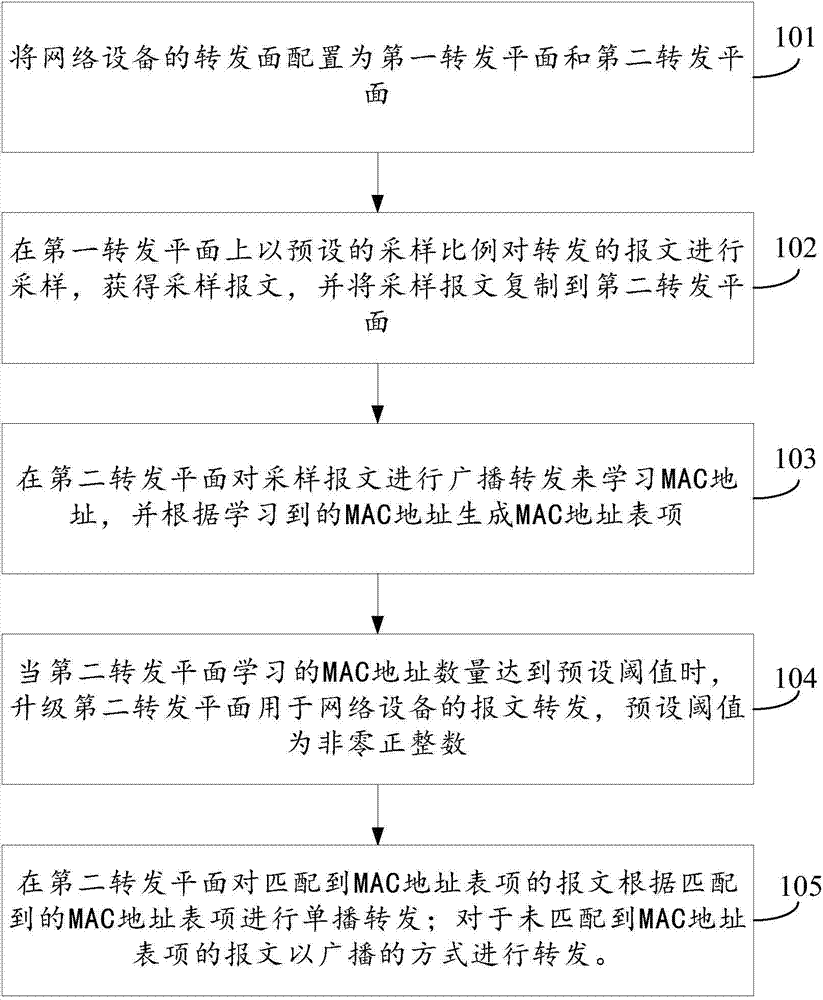

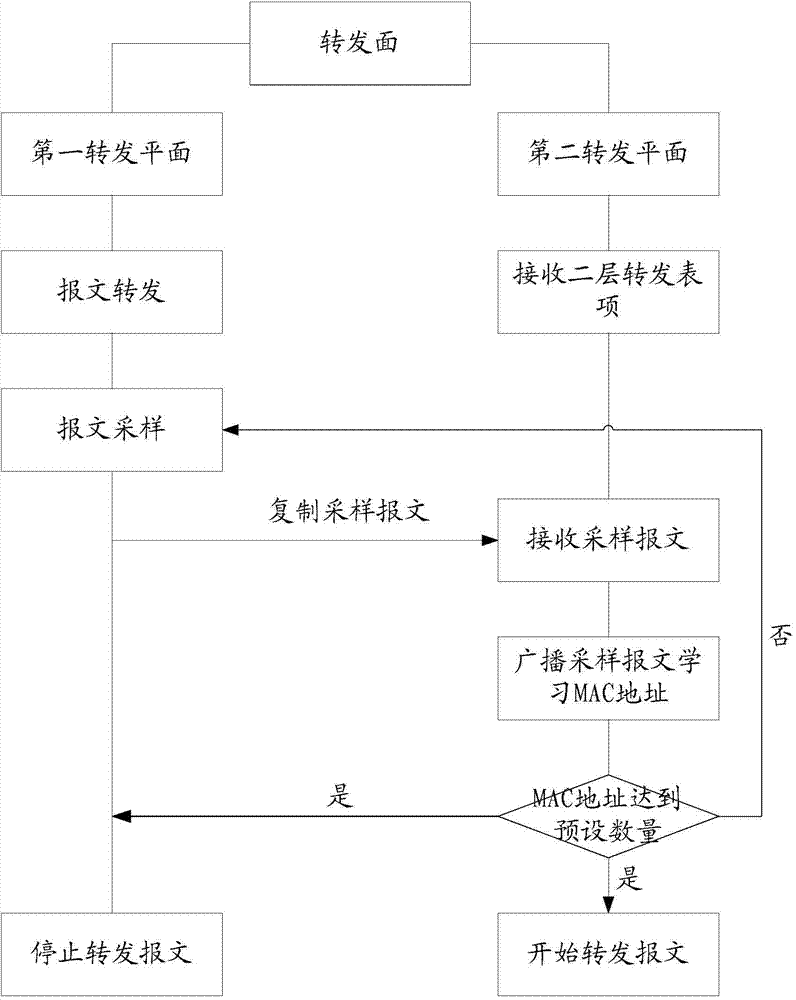

Method of version upgrade of network device and network device

ActiveCN103843285AAvoid congestionAvoid it happening againData switching networksForwarding planeDistributed computing

Embodiments of the invention disclose a method of a version upgrade of a network device and a network device relating to the field of communications. The method of the version upgrade of the network device and the network device resolve a technical question that network congestions are caused by overmuch occupations of network bandwidths caused by forwards of a large number of broadcast messages during the version upgrade of the network device. The concrete proposals are that: forwarding planes of the network device are configured into a first forwarding plane and a second forwarding plane, forwarding messages are sampled on the first forwarding plane by a preset sampling proportion to acquire sampling messages, and the sampling messages are performed broadcast forwards by the second forwarding plane to learn MAC addresses. When the amount of learned MAC addresses by the second forwarding plane achieves a preset threshold, the broadcast forwards of the network device of the second forwarding plane is upgraded. The technical proposals provided by the embodiments of the invention can effectively avoid generations of a large number of the broadcast messages during the course of the version upgrade, be capable of reducing the overmuch occupations of the network bandwidths, and avoid the network congestions.

Owner:HUAWEI TECH CO LTD

Four-axis linkage milling machine processing method for steam turbine blade

PendingCN109894827AReduce processing costsShorten the processing cycleWork in processRadial position

The invention relates to a four-axis linkage milling machine processing method for a steam turbine blade. The steam turbine blade structurally comprises four parts: an inner arc, a back arc, a steam outlet edge and a steam inlet edge. The four-axis linkage milling machine processing method for the steam turbine blade comprises the processing steps of clamping a blank onto a pair of flat tongs of acommon milling machine, and utilizing an end mill clamped on a port of the common milling machine for processing a blade root end surface and a blade crown end surface through a rough milling processand a finish milling process; clamping the processed blank onto a three-tip fixture on a four-axis milling machine, adopting a ball-end cutter arranged on a port of the four-axis milling machine forsegmentally processing the blade root end surface, a middle boss and the blade crown end surface, cushioning a cushion block to the bottom part of the blade root end surface, and meanwhile, using a molded line sample plate, a back radial position sample plate, an inner radial position sample plate, a blade crown inner radial direction and a steam inlet side sample plate for measuring; and clampinga semi-finished blade onto a polishing machine for polishing, clamping a polished semi-finished product onto a milling total length fixture of the common milling machine, and scribing and cutting theblade crown inner back radial direction. The processing cost is reduced, the processing period is shortened, and the product quality is improved.

Owner:常州凯度机电有限公司

Efficient ladle baking device

The invention provides an efficient ladle baking device. The efficient ladle baking device comprises a baking device body, a cover and a flame retardant layer, wherein the lower end of the baking device body is connected with the upper end of the cover; the lower end of the cover is connected with the flame retardant layer; the lower end of a burner composed of a conical body, a flow mixing cavity, an electronic igniter, a combustion cavity and a firing stabilizer is arranged at the lower end of the flame retardant layer, and the upper end of the burner is arranged on the upper portion inside the baking device body; the upper end of the burner is connected with an air cavity through an electric adjustment valve; an air heat exchanger is installed on the lower portion of the air cavity; one end of the air heat exchanger is connected with a smoke inlet, and the other end of the air heat exchanger is connected with a smoke outlet; an air inlet is formed in the lateral surface of the cover; the upper end of the burner is provided with a fuel gas inlet communicating with an outlet of a fuel gas heat exchanger; the conical body is arranged at the fuel gas inlet of the burner; an inlet of the fuel gas heat exchanger is connected with a fuel gas pipeline through a fuel gas valve and a flowmeter; and the ladle baking device is further provided with an intelligent control device. The efficient ladle baking device has the advantages of saving energy and labor, improving safety performance and the like.

Owner:大连新瑞晨环保科技有限公司

Unwatched plant watering device

ActiveCN104686293AReduce overuseFlexible sprinkler operationWatering devicesCultivating equipmentsLawnAgricultural engineering

Owner:NANTONG INST OF TECH

A Machining Technology of Axial Flow Turbine Blade

Owner:南京赛达科技有限公司

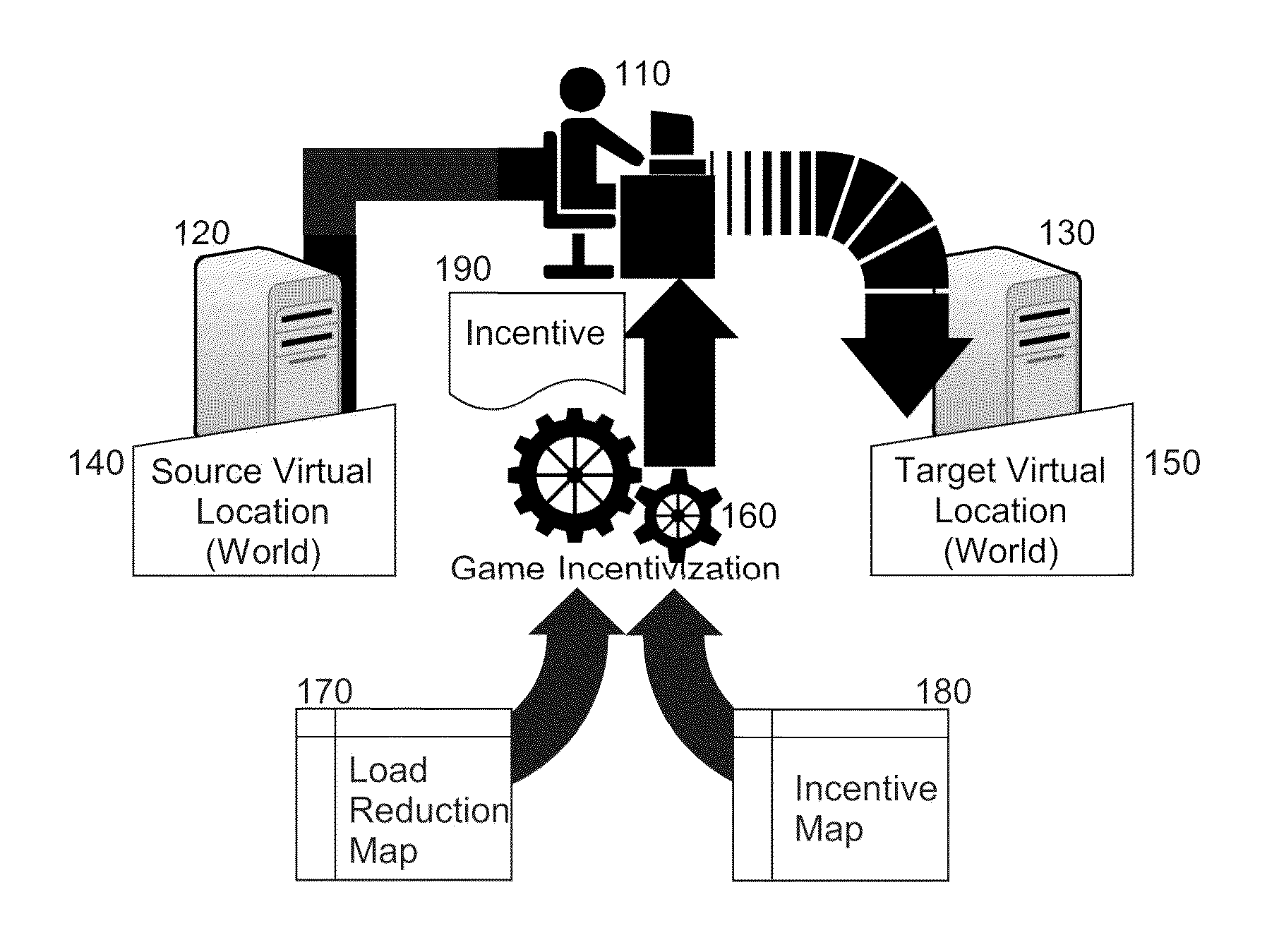

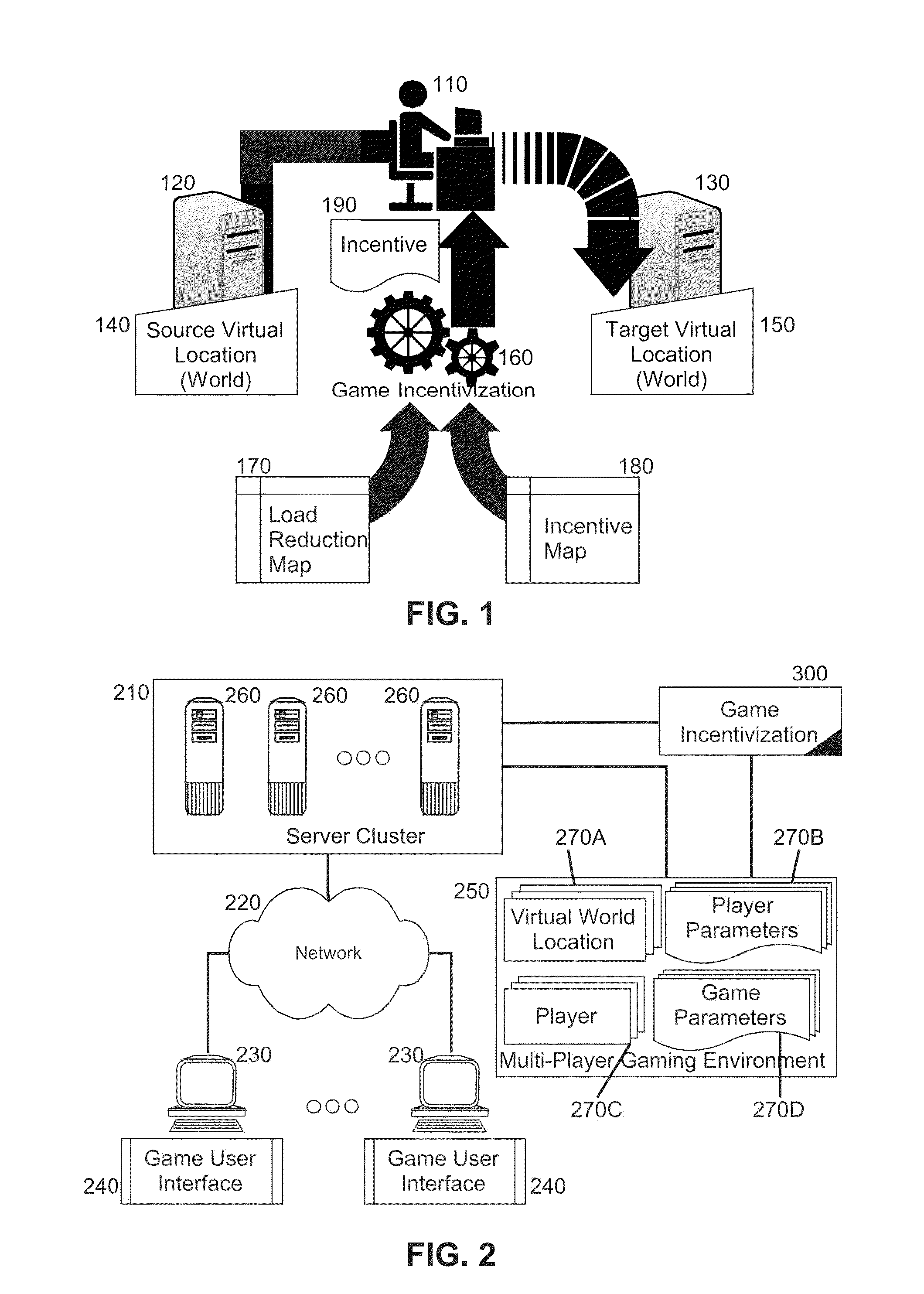

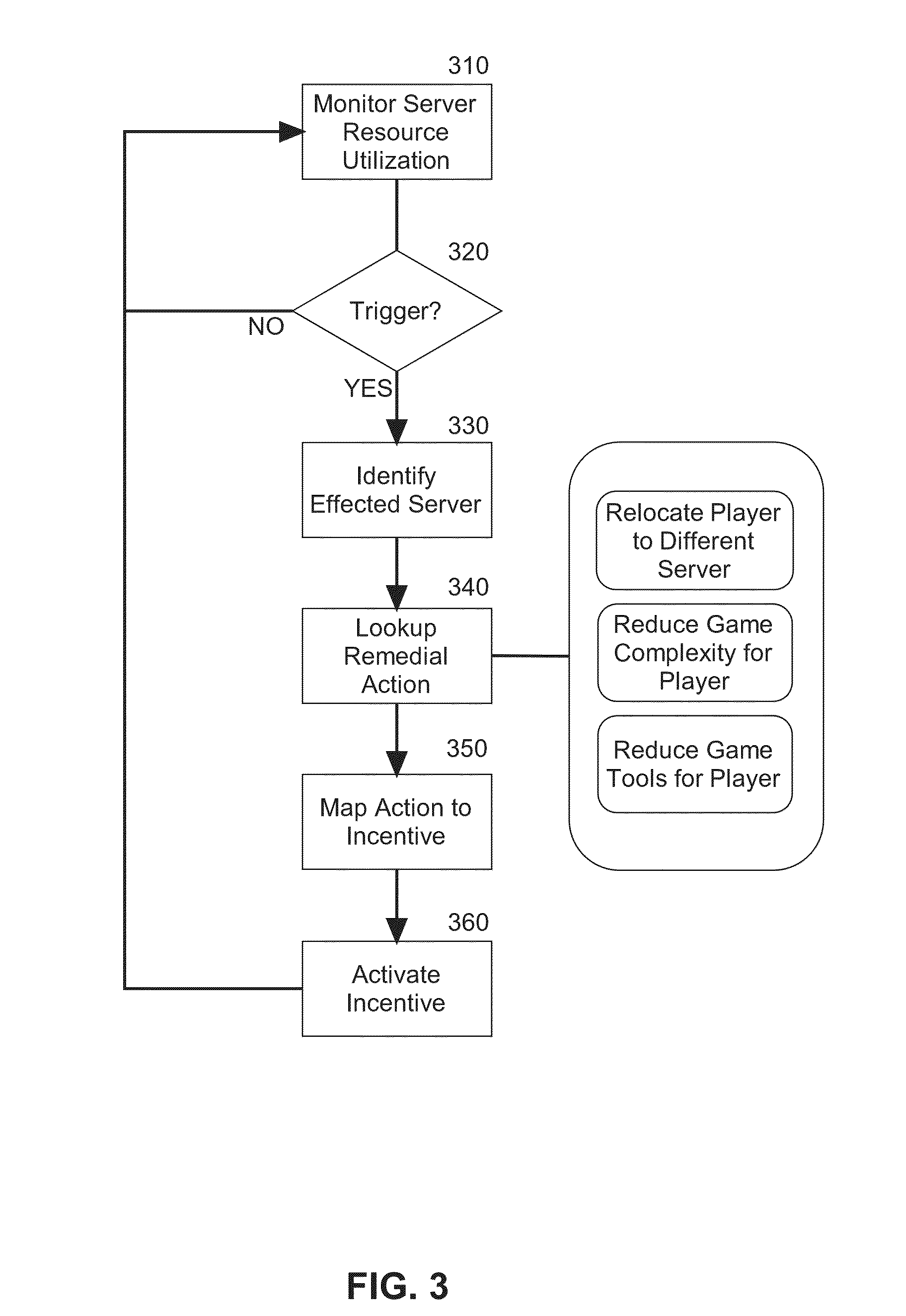

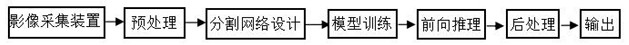

Game incentivized optimization of resource utilization

ActiveUS20150265919A1Reduce overuseImprove resource utilizationVideo gamesSpecial data processing applicationsResource utilizationRemedial action

Embodiments of the present invention provide a method, system and computer program product for game incentivized resource utilization optimization in a multiplayer gaming environment. In an embodiment of the invention, a method for game incentivized resource utilization optimization in a multiplayer gaming environment is provided. The method includes hosting a multiplayer gaming environment providing a game amongst a selection of servers in a cluster and detecting overutilization of a resource in one of the servers. A remedial action likely to reduce the overutilization can be identified as can an incentive of the game likely to provoke the identified remedial action. Thereafter, the identified game incentive can be provided to a player in the multiplayer gaming environment.

Owner:LENOVO GLOBAL TECH INT LTD

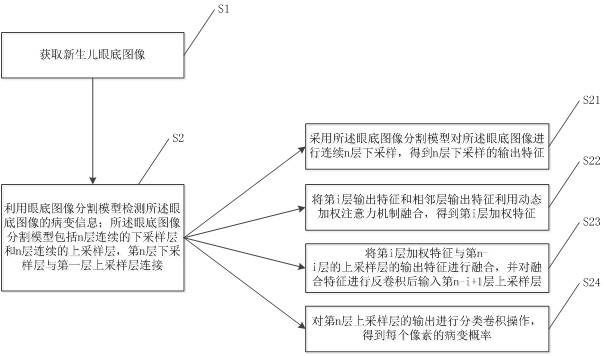

Eye fundus image detection method and system based on dynamic weighted attention mechanism

ActiveCN114708258AGuaranteed recognition accuracyReduce complexityImage enhancementImage analysisImage segmentationNetwork model

The invention relates to an eye fundus image detection method and system based on a dynamic weighted attention mechanism, and relates to the technical field of image processing. And detecting lesion information of the eye fundus image of the premature infant by using the eye fundus image segmentation model. Firstly, continuous down-sampling is carried out on an eye fundus image, dynamic weighted attention fusion is carried out on obtained down-sampling features and down-sampling features obtained in an adjacent layer, then the features after weighted fusion are fused with output features of corresponding up-sampling layers, and finally classification convolution operation is carried out on output of the n up-sampling layer. And obtaining the lesion probability of each pixel. According to the method, hierarchical feature fusion and a dynamic weighted attention mechanism are carried out on the shallow network model, and the purposes of reducing the complexity of algorithm design, reducing the operation time of the algorithm and reducing excessive occupation of GPU resources can be achieved while the recognition accuracy is ensured.

Owner:BEIJING ZHENHEALTH TECH CO LTD

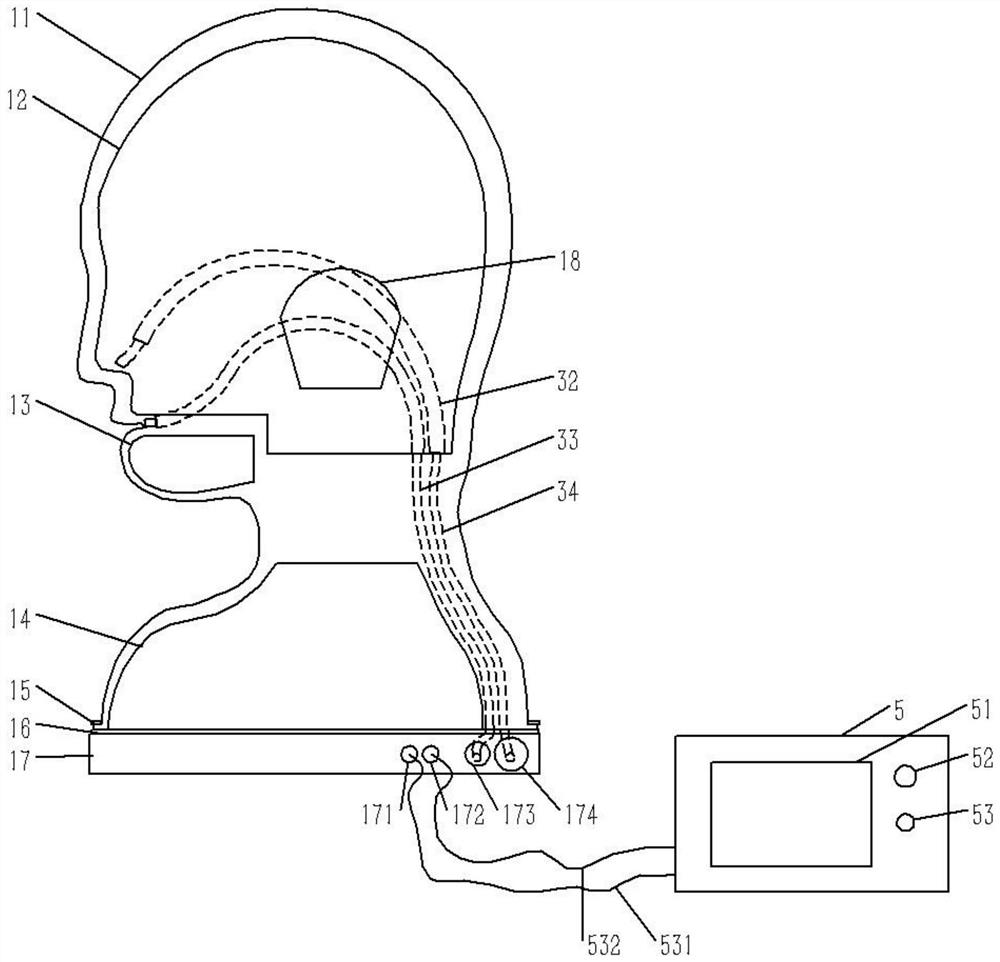

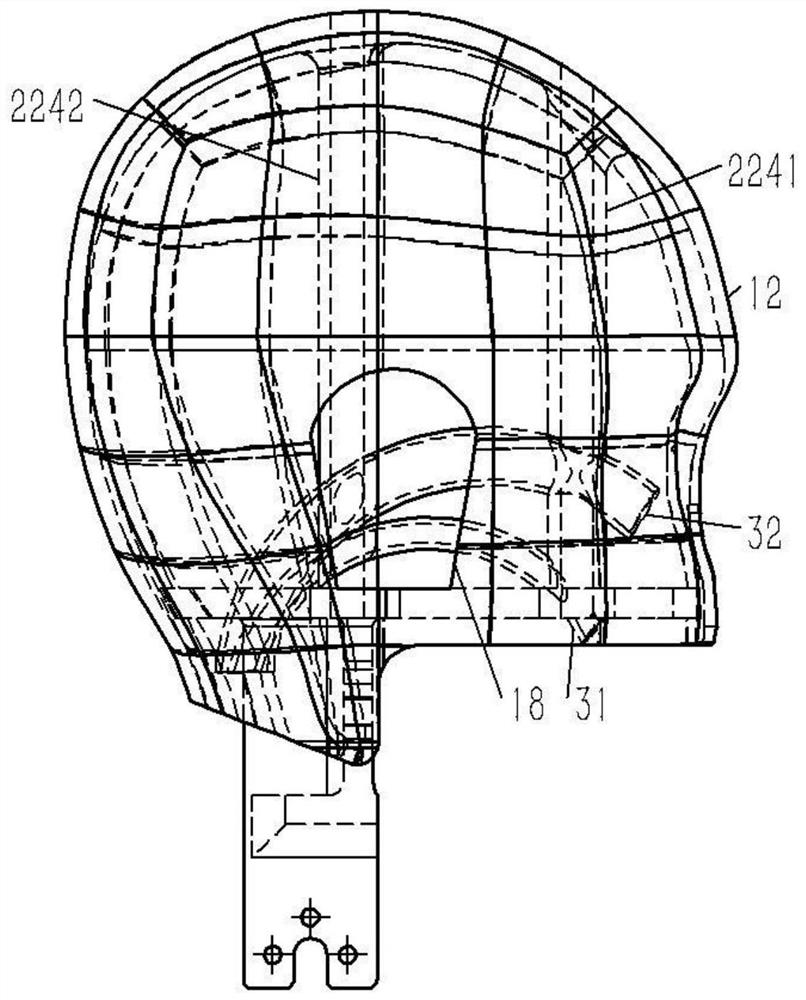

Intelligent humanoid head model for testing child mask and child mask testing method

PendingCN111781125AAvoid vibrationMitigate high occupancyProgramme controlComputer controlNasal passagesSimulation

The invention discloses an intelligent humanoid head model for testing a child mask and a child mask testing method. The intelligent humanoid head model comprises a head model outer sleeve, a head model inner shell, a control box, a head shaking mechanism arranged in the head model inner shell, a nodding mechanism, a mouth opening and closing mechanism, a nasal cavity hose and an oral cavity hose.The control box controls the humanoid head model to complete head shaking motion, nodding motion and mouth opening and closing motion in the mask tester, and detection of the child mask is completed.The defects that in the prior art, due to imperfect design of all action mechanisms, accumulated errors are large, too much space is occupied, and vibration is prone to occurring in the movement process, a control system is difficult to maintain in the later period, and angle information cannot be fed back in real time are overcome. The movement precision of the movement mechanism is improved, the occupied space is reduced, and the oral-nasal cavity catheter and the angle sensor are reasonably arranged to achieve real-time feedback of angle information in the movement process.

Owner:佛山市顺德致可智能科技有限公司

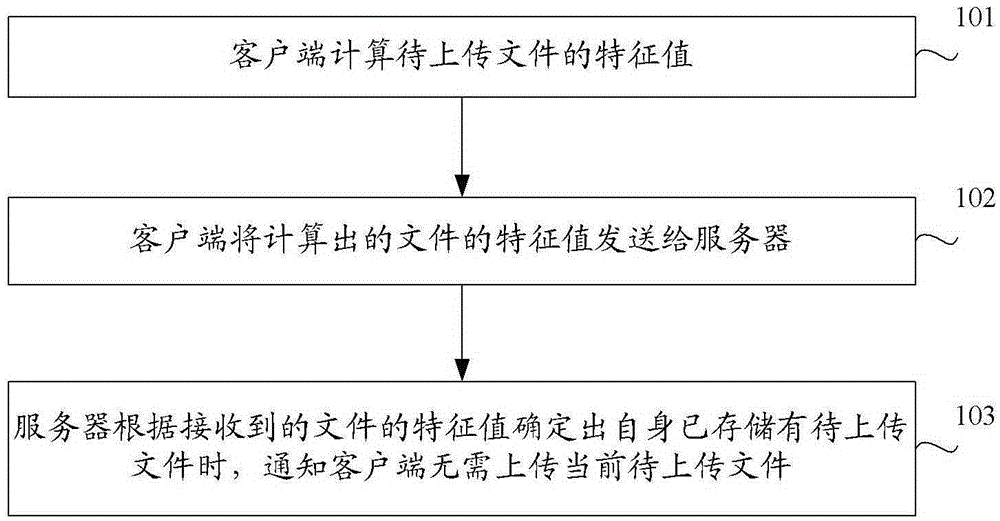

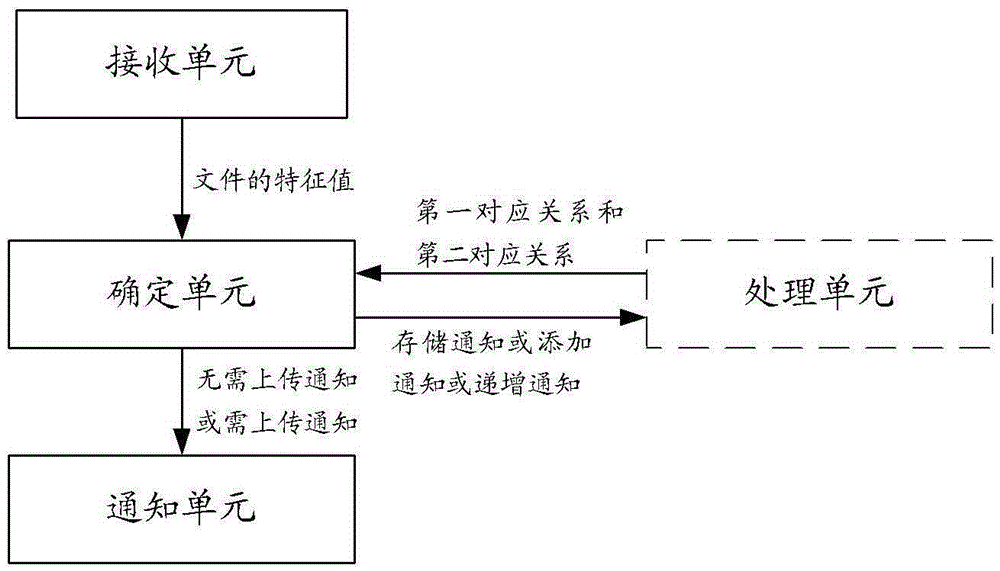

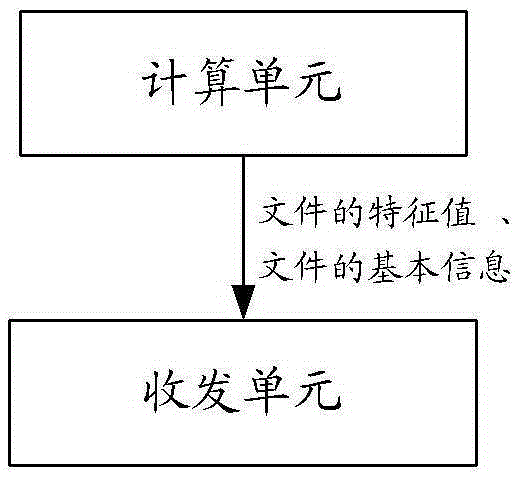

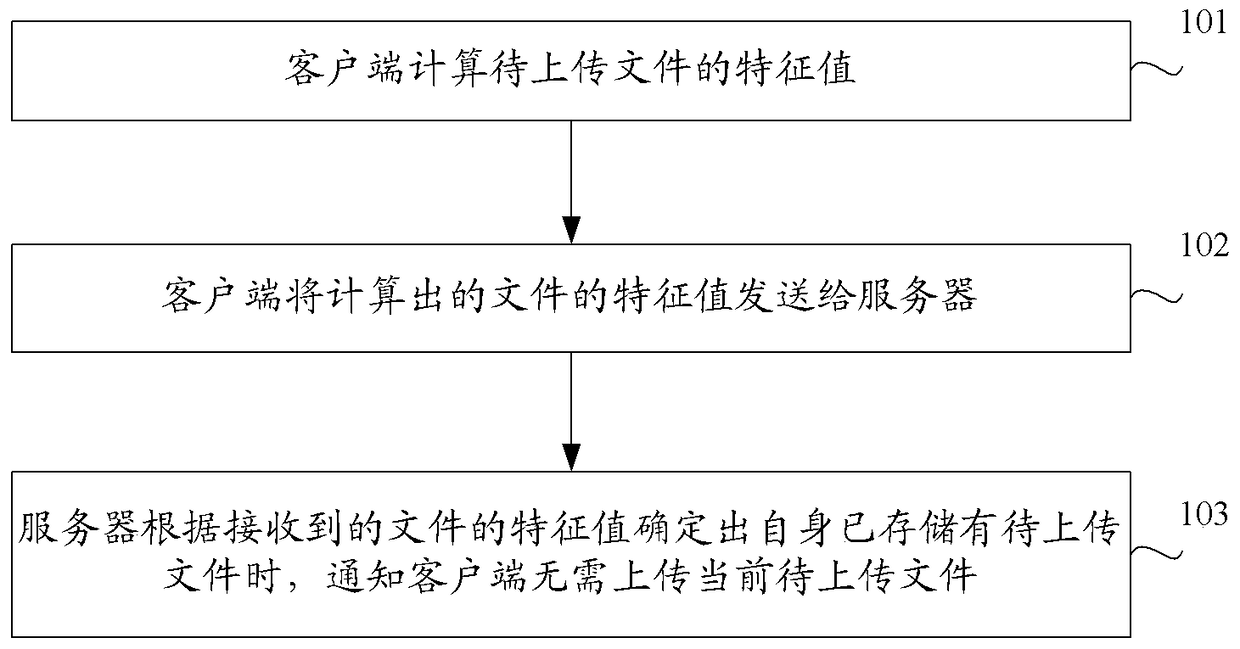

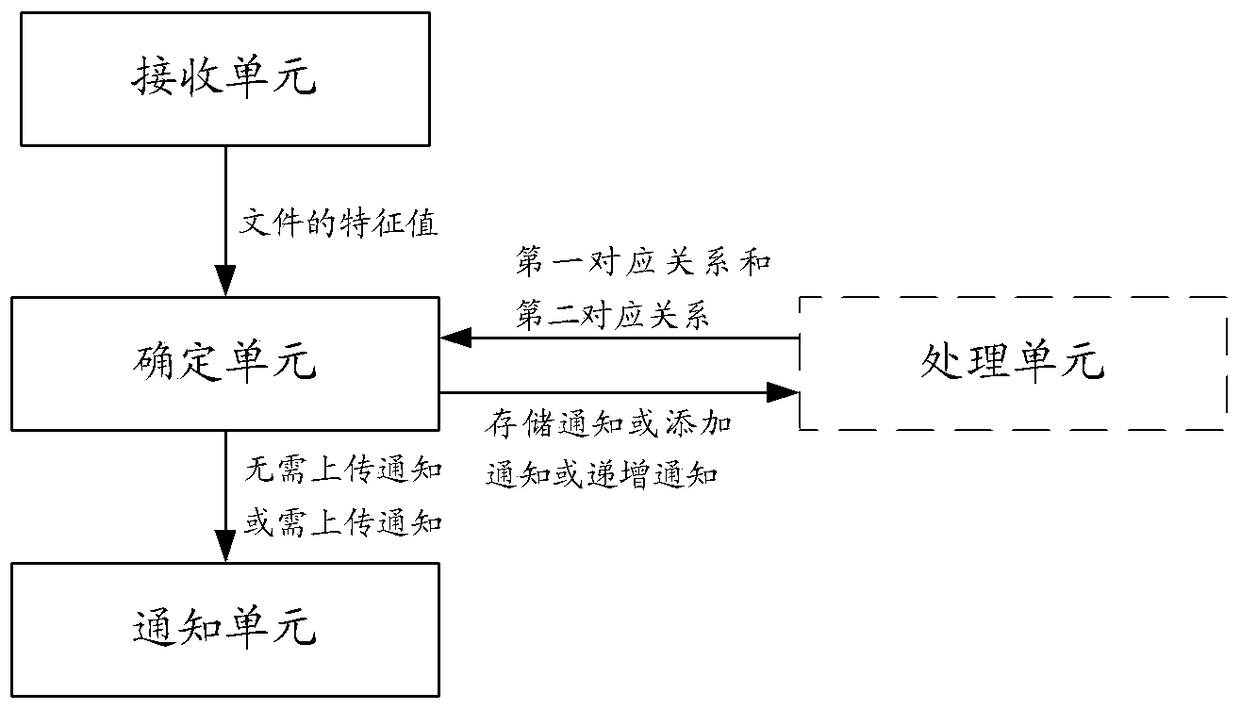

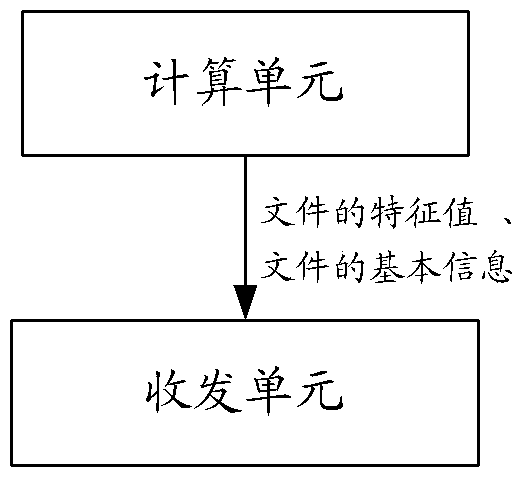

Method for transmitting files of office automation (OA) system, server and client

ActiveCN105306537AImprove upload efficiencyReduce overuseOffice automationTransmissionClient-sideOffice automation

The invention discloses a method for transmitting files of an office automation (OA) system, a server and a client. The method comprises the following steps that: the client calculates a feature value of a file to be uploaded; the client transmits the calculated feature value of the file to the server; and when the server determines that the file to be updated is already stored in the server according to the received feature value of the file, the server informs the client that the current file to be uploaded does not need to be uploaded. Through adoption of the technical scheme of the invention, excessive occupation of bandwidths is reduced, and the file uploading efficiency and the office efficiency of an OA system are increased.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

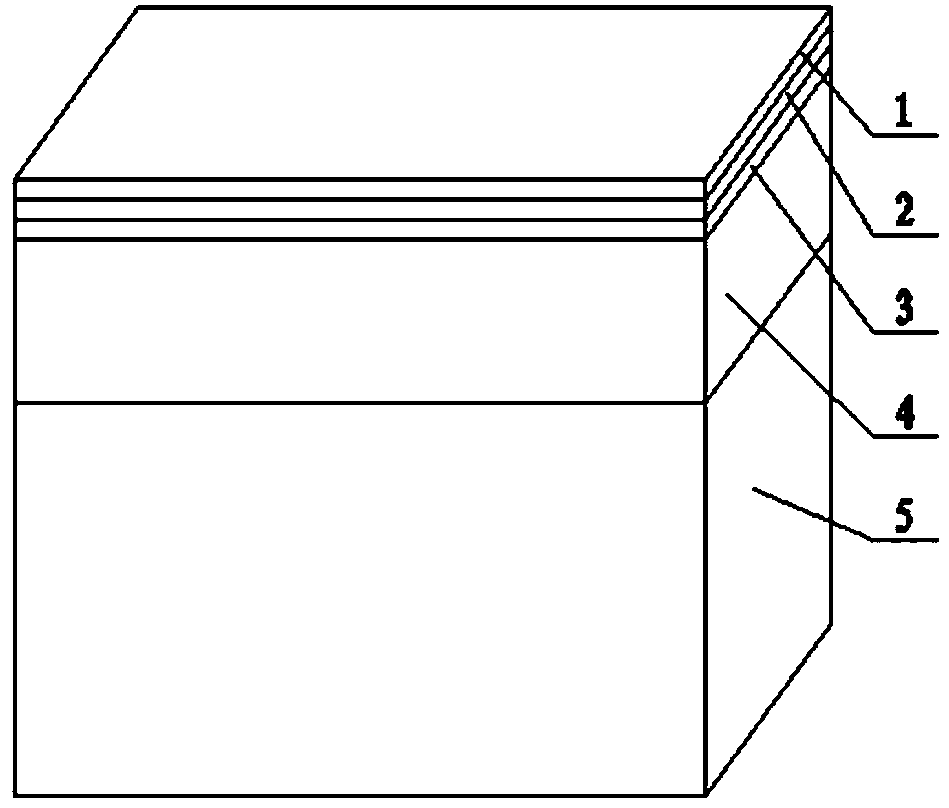

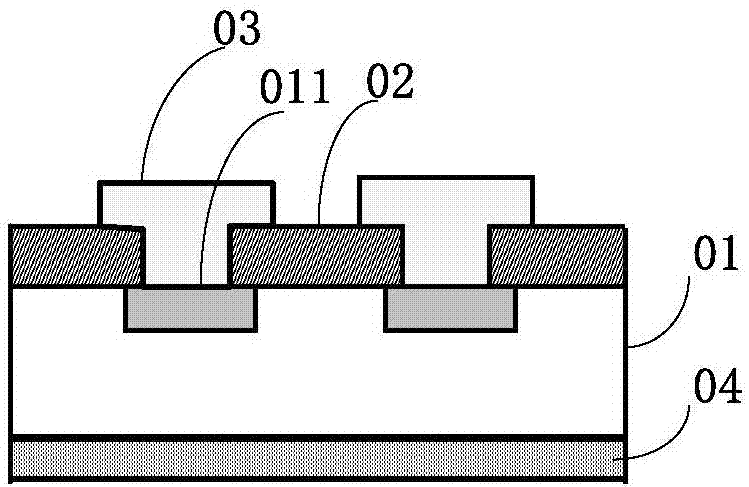

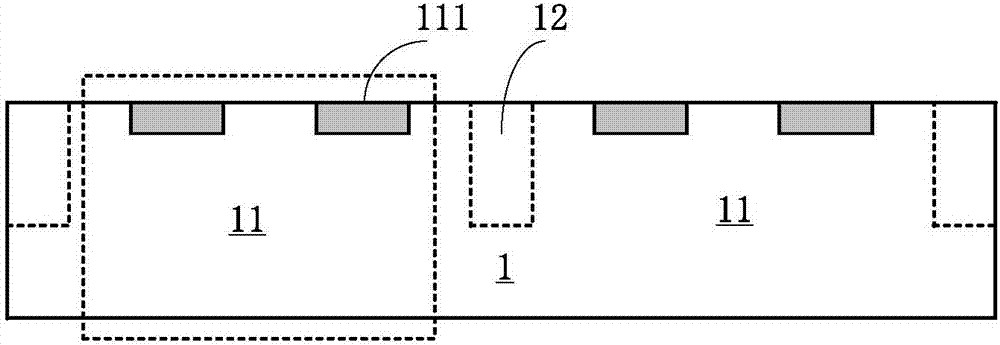

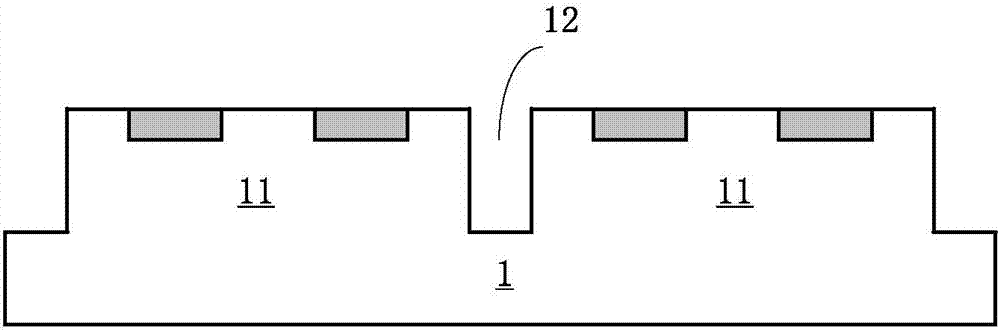

Semiconductor process and semiconductor structure

InactiveCN107342256AReduce depth of cutReduce overuseSolid-state devicesSemiconductor/solid-state device manufacturingUnit structureEngineering

The invention provides a semiconductor process and a semiconductor structure. A semiconductor substrate is half cut in the front, then a protective membrane is arranged on the front of the semiconductor substrate, and then the semiconductor substrate is thinned in the back so as to separate each semiconductor unit structure, so that reduced cutting depth prevents a cutting knife from being overused, an active surface of the semiconductor substrate is protected from damage in the process of separating each semiconductor unit, and each semiconductor unit is prevented from deviating in separation. In addition, according to the semiconductor process provided in the invention, the front of the semiconductor substrate is protected by the protective membrane, then plastic packaging and cutting of a plastic packaging material are carried out, so that bad effect of plastic packaging on the front of the semiconductor substrate is prevented; and each of six surfaces of finally formed semiconductor structure has a protective layer, thereby preventing bad effect of external environment on the semiconductor structure, and improving the reliability of the semiconductor structure.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

Method for extracting anthocyanins and ursolic acid from perilla leaves

ActiveCN105732741BTake advantage ofReduce manufacturing costSugar derivativesSteroidsUrsolic acidBULK ACTIVE INGREDIENT

The invention provides a method for extracting anthocyanin and ursolic acid from perilla leaves. The crystals of ursolic acid and anthocyanin are obtained by a method combining enzyme deactivation, petroleum ether degreasing, acid water extraction, resin and crystallization. Through the acid water extraction technology, a large amount of high-purity water-soluble anthocyanin is obtained, the anthocyanin extraction rate is effectively increased, and the risk of environmental pollution caused by insufficient utilization of anthocyanin is reduced. Through enzyme deactivation and petroleum ether degreasing, the damage of anthocyanin and ursolic acid caused by enzyme can be effectively prevented while the cells of perilla leaves are damaged and quick release of active ingredients in the leaves can be promoted.

Owner:广东冠龙生物科技有限公司

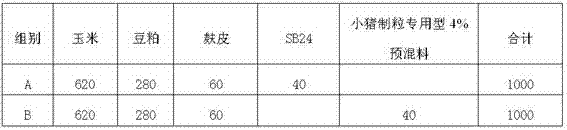

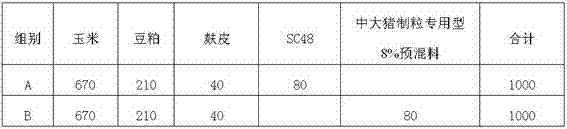

Special feed core material for granulation and feed prepared from material

ActiveCN103750014AMeet the nutritional needs for normal growth and developmentReduce anti-nutritional factorsAnimal feeding stuffNutritive valuesProcess engineering

The invention discloses a special feed core material for granulation and a feed prepared from the material. The special feed core material is characterized in that each 1,000 parts of special feed core material comprises the following raw materials in parts by weight: 106-135 parts of vitamin, 345-400 parts of amino acid, 35-76 parts of a medical feed additive, 139-181 parts of microecologics, 58-100 parts of a particle swelling agent and the balance being carriers. The special feed core material is added with the raw materials including corn, bean pulp and the like according to a proper main ingredient formula, and pig granulated feeds meeting the requirements of different stages of pigs can be produced by utilizing a matched small-size granulation machine. According to the special feed core material, a nutritional ingredient loss phenomenon occurring in a processing process of a granulated complete feed can be avoided, the maximum of the nutritive value is realized, and an optimal utilization effect is realized; the produced granulated complete feed is good in palatability and digestive performance and high in crispness, the whole operation process is convenient and rapid, the quality is controllable, and the cost is low.

Owner:河南雄峰科技股份有限公司

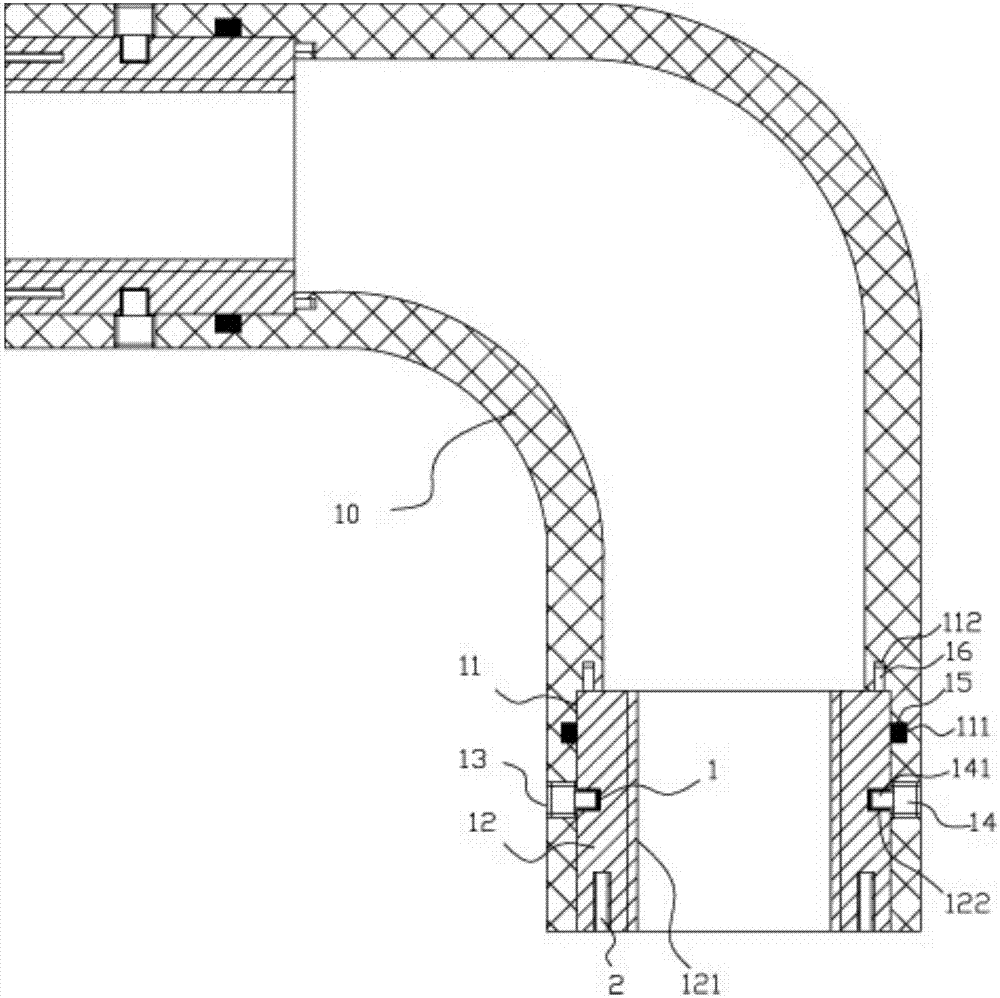

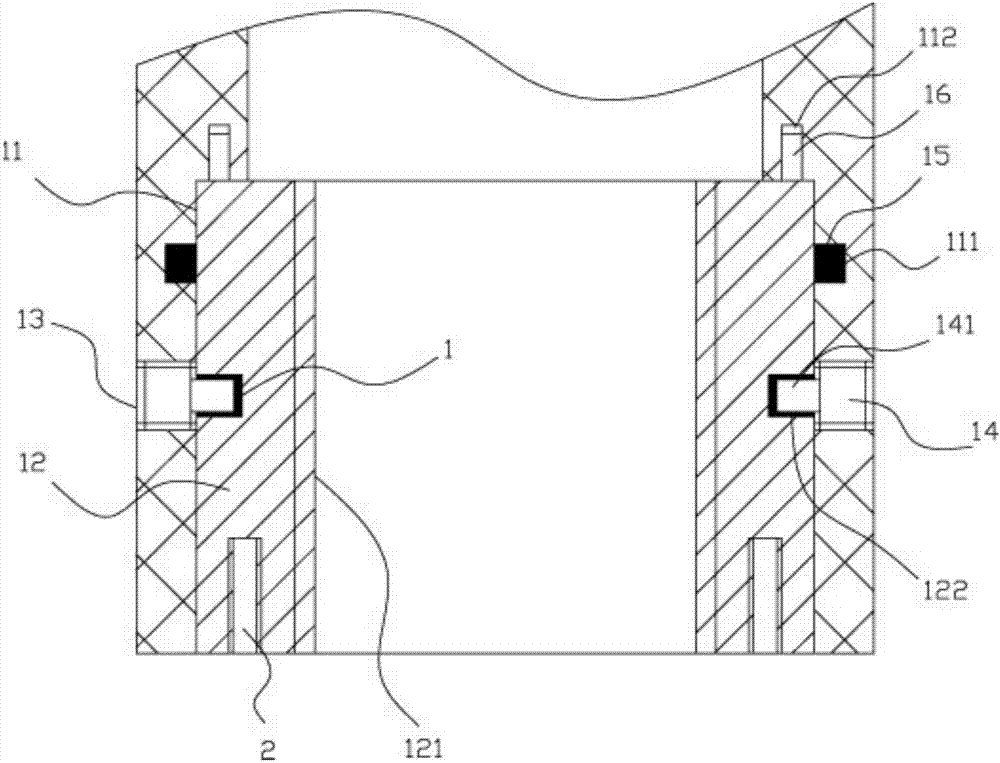

Bend pipe fitting

InactiveCN106996494AShorten the lengthReduce overuseSiphonsScrew threaded jointsPipe fittingEngineering

The invention discloses a bend pipe fitting. The bend pipe fitting comprises a bend body. Annular grooves are formed in the inner side walls of two connectors of the bend body, connecting sleeve bodies are inserted into the end of the bend body in a sleeved manner, the exteriors of the connecting sleeve bodies are inserted into the corresponding annular grooves in a sleeved manner, the outer side walls of the connecting sleeve bodies abut against the inner side walls of the annular grooves in a pressed manner, and internal threads are arranged on the inner side walls of the connecting sleeve bodies. Multiple screw joint through holes are formed in the outer side walls of the connectors of the bend body, the screw joint through holes correspond to positioning concave holes formed in the outer side walls of the connecting sleeve bodies, positioning blocks are in screw joint with the interiors of the screw joint through holes, convex parts are arranged at the ends of the positioning blocks, and the convex parts are inserted into the corresponding positioning concave holes in a sleeved manner. The bend body and the connecting sleeve bodies are connected in a positioning manner, when the connecting sleeve bodies are in screw loose, it is only needed to replace the connecting sleeve bodies, the cost is reduced, and the effect is good.

Owner:湖州高锐工贸有限公司

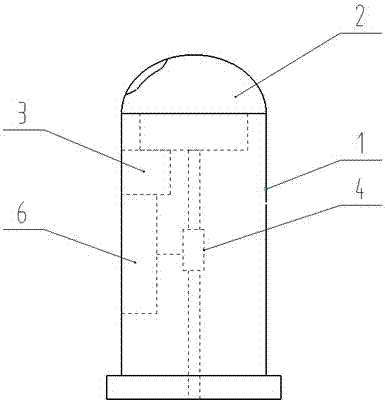

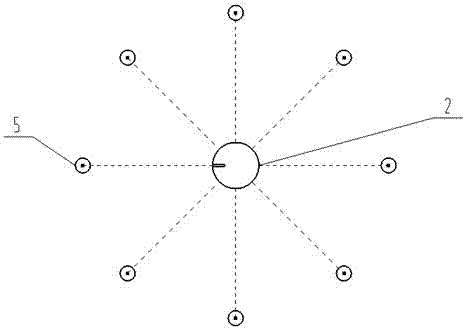

An unattended plant watering device

ActiveCN104686293BReduce overuseFlexible sprinkler operationWatering devicesCultivating equipmentsDrive shaftMagnetic valve

The present invention designs an unattended plant watering device, which includes a protective shell, a rotary nozzle, a rotary motor, a solenoid valve, a humidity sensor and a controller. The protective shell is a cylinder, and the top of the protective shell is provided with a rotary sprinkler. The drive shaft of the rotary motor is fixedly connected, and the rotary nozzle is connected with a solenoid valve. The rotary motor and the solenoid valve are connected to the controller fixed inside the protective shell through wires, and the controller communicates with the humidity sensor set outside the protective shell through wires. . Through the combined use of rotating nozzles, rotating motors, solenoid valves, humidity sensors and controllers, it can flexibly perform sprinkling operations according to the dry humidity of the lawn, effectively reducing the excessive use of water resources, and is suitable for lawn watering in a wide range. Very high economic value.

Owner:NANTONG INST OF TECH

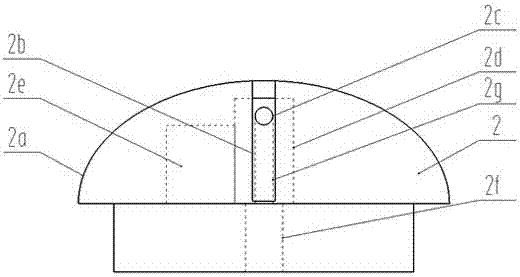

Environment-friendly dry anti-seepage material suitable for aluminum electrolysis cell

The invention discloses an environment-friendly dry anti-seepage material suitable for an aluminum electrolysis cell. The environment-friendly dry anti-seepage material is prepared from 60-68 parts offlint clay clinker; 15-23 parts of fly ash with particle size less than 0.1 mm; 5-13 parts of coal gangue clinker with particle size of 1-0 mm; 6-10 parts of quartz sand with particle size less than0.088 mm; 3-5 parts of raw clay with particle size less than 0.088 mm and 2-4 parts of an anti-seepage additive with particle size less than 0.074 mm. According to the invention, high-quality coal waste fly ash is used as a main raw material, the raw material source is wide, the quality is stable, the volume of the power plant fly ash is stable after high temperature, the texture is uniform, the heat preservation performance is good, and the price is low; at the same time, the risk of occupying land and harming the environment caused by accumulation of the fly ash is solved, and waste is turned into treasure.

Owner:INNER MONGOLIA FENGGUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD +1

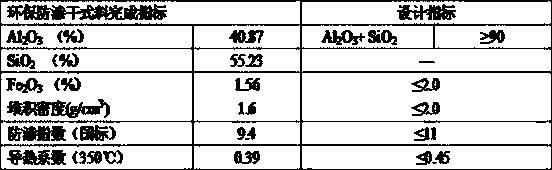

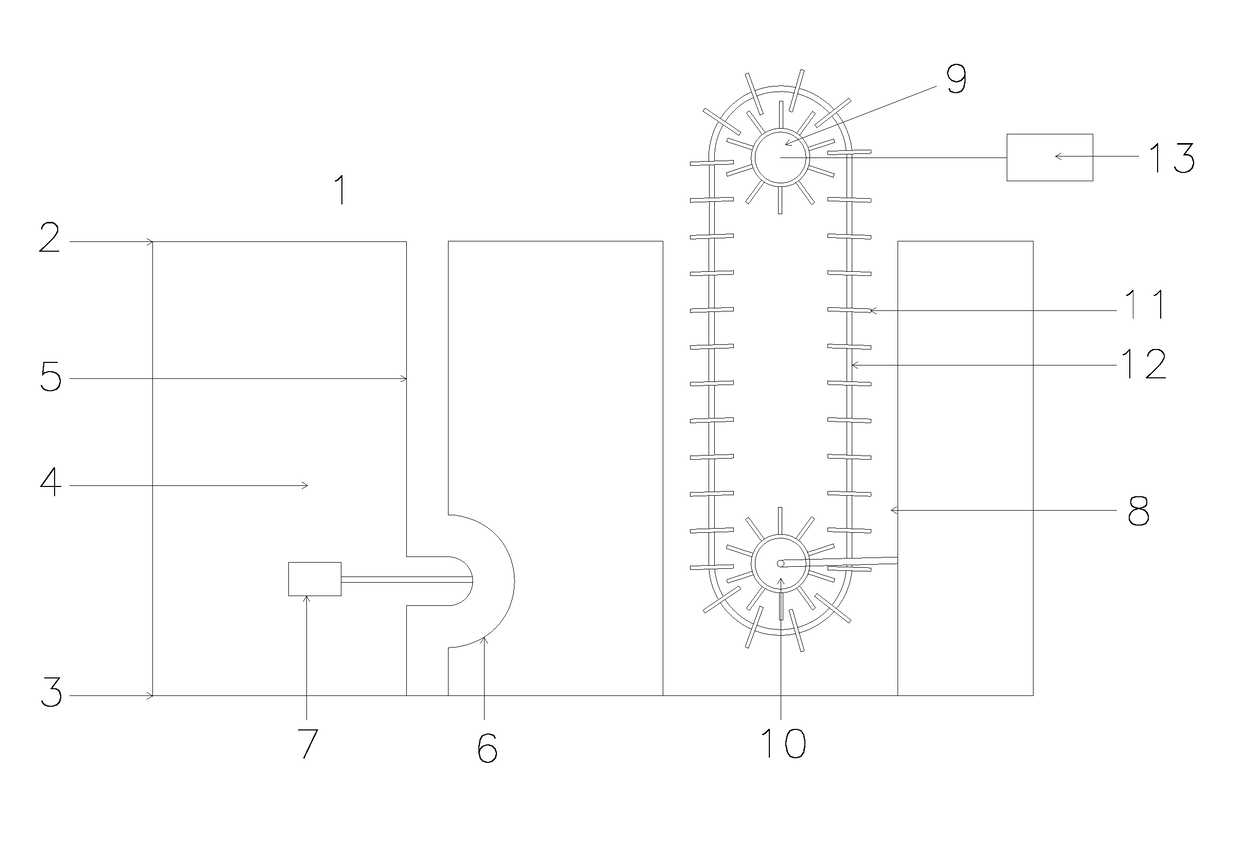

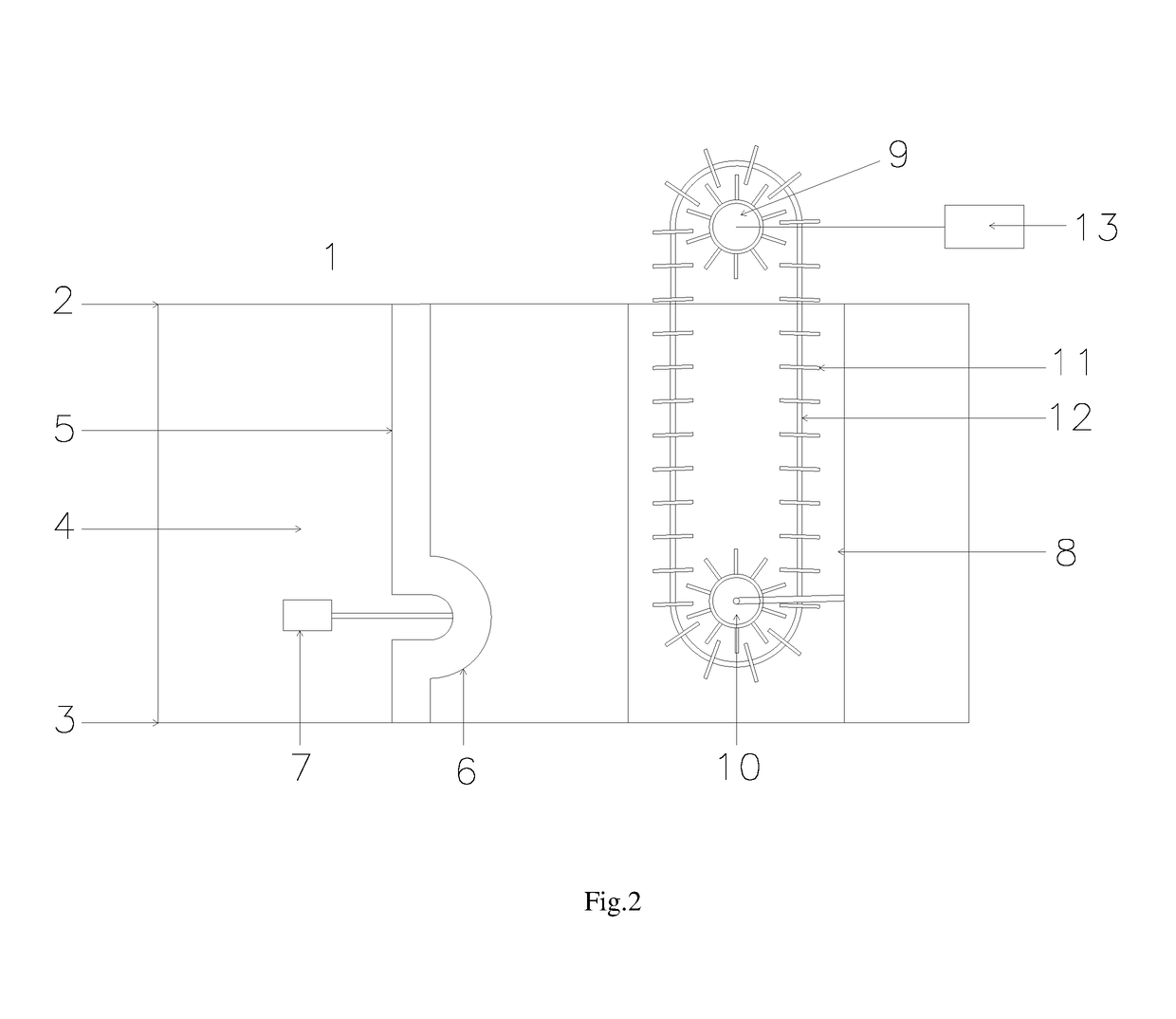

Anti-drought and Anti-flood by still water circulation generation

InactiveUS20180030950A1Speed up the flowInsufficient dischargeEngine fuctionsHydro energy generationWater turbineWater circulation

The present disclosure discloses anti-drought and anti-flood by still water circulation generation. A pit (4) is dug near water (1), a water turbine (6) and a generator (7) are placed at the bottom of the pit, the water (1) on the pit (4) is released in a planned way along a water discharge pipe to drive a water turbine (6) to operate, a blade (11) and a chain (12) are meshed with an upper gear (9) and a lower gear (10), the upper gear (9) is driven by an electric motor (13) to drive the blade (11) to rotate such that the blade (11) inside a water outlet pipe moves upwards with water (1) circularly, thereby driving the generator to continuously generate power. The present invention is able to meet the power generation demand of users and is also capable of adjusting and meeting the local water consumption.

Owner:ZHONG TAIPING

A method, server and client for transferring files of an office automation system

ActiveCN105306537BImprove upload efficiencyReduce overuseOffice automationTransmissionClient-sideOffice automation

The invention discloses a method for transmitting files of an office automation (OA) system, a server and a client. The method comprises the following steps that: the client calculates a feature value of a file to be uploaded; the client transmits the calculated feature value of the file to the server; and when the server determines that the file to be updated is already stored in the server according to the received feature value of the file, the server informs the client that the current file to be uploaded does not need to be uploaded. Through adoption of the technical scheme of the invention, excessive occupation of bandwidths is reduced, and the file uploading efficiency and the office efficiency of an OA system are increased.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com