Environment-friendly dry anti-seepage material suitable for aluminum electrolysis cell

An aluminum electrolytic cell and environmentally friendly technology, applied in the field of aluminum electrolysis, can solve the problems of potential safety hazards, uneven mixing of materials, insufficient fire resistance, etc., and achieve the effects of reducing raw material costs, reducing pollution, and improving market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An environment-friendly dry anti-seepage material, the mass composition is: 25 parts of burnt gemstone clinker with a particle size of 5-3mm mm; 20 parts of burnt gemstone clinker with a particle size of 3-1mm; 15. 1-0mm gangue clinker: 5 parts;

[0053] Fly ash with particle size <0.1mm: 23 parts;

[0054] Quartz sand with particle size <0.088mm: 6 parts;

[0055] Raw clay with particle size <0.088mm: 3 parts;

[0056] Anti-seepage additive aluminum titanate with particle size <0.074mm: 3 parts.

[0057] Then add the above raw materials and admixtures weighed accurately into a vertical forced mixer and mix for 6-8 minutes, then pack.

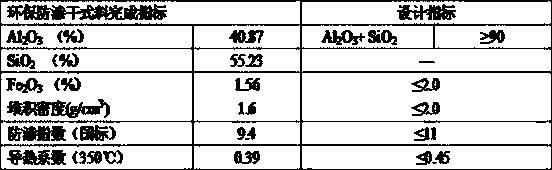

[0058] The performance result is:

[0059] Refractoriness, ℃ 1632

[0060] Compacted bulk density (g / cm 3 ) 1.63

[0061] Cryolite penetration depth, mm 9.3

[0062] Thermal conductivity (350°C) 0.38.

Embodiment 2

[0064] An environment-friendly dry anti-seepage material, the mass composition is: 30 parts of burnt gemstone clinker with a particle size of 5-3mm mm; 25 parts of burnt gemstone clinker with a particle size of 3-1mm; 10. 1-0mm gangue clinker: 10 parts;

[0065] Fly ash with particle size <0.1mm: 21 parts;

[0066] Quartz sand with particle size <0.088mm: 7 parts;

[0067] Raw clay with particle size <0.088mm: 4 parts;

[0068] Anti-seepage additive aluminum titanate with particle size <0.074mm: 3 parts.

[0069] Then add the above raw materials and admixtures weighed accurately into a vertical forced mixer and mix for 6-8 minutes, then pack.

[0070] The performance result is:

[0071] Refractoriness, ℃ 1632

[0072] Compacted bulk density (g / cm 3 ) 1.66

[0073] Cryolite penetration depth, mm 9.4

[0074] Thermal conductivity (350°C) 0.39.

Embodiment 3

[0076] An environment-friendly dry anti-seepage material, the mass composition is: 35 parts of burnt gemstone clinker with a particle size of 5-3mm mm; 15 parts of burnt gemstone clinker with a particle size of 3-1mm; 15. 1-0mm gangue clinker: 15 parts;

[0077] Fly ash with particle size <0.1mm: 21 parts;

[0078] Quartz sand with particle size <0.088mm: 7 parts;

[0079] Raw clay with particle size <0.088mm: 4 parts;

[0080] Anti-seepage additive aluminum titanate with particle size <0.074mm: 3 parts.

[0081] Then add the above raw materials and admixtures weighed accurately into a vertical forced mixer and mix for 6-8 minutes, then pack.

[0082] The performance result is:

[0083] Refractoriness, ℃ 1635

[0084] Compacted bulk density (g / cm 3 ) 1.65

[0085] Cryolite penetration depth, mm 9.4

[0086] Thermal conductivity (350°C) 0.39.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| Penetration depth | aaaaa | aaaaa |

| Penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com