Bend pipe fitting

A technology for elbows and elbows, which is applied in the directions of elbows, pipe components, pipes/pipe joints/fittings, etc., can solve the problems that the thread of the joint is prone to slippage and the replacement cost is high, and can reduce the length and reduce too much. occupied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

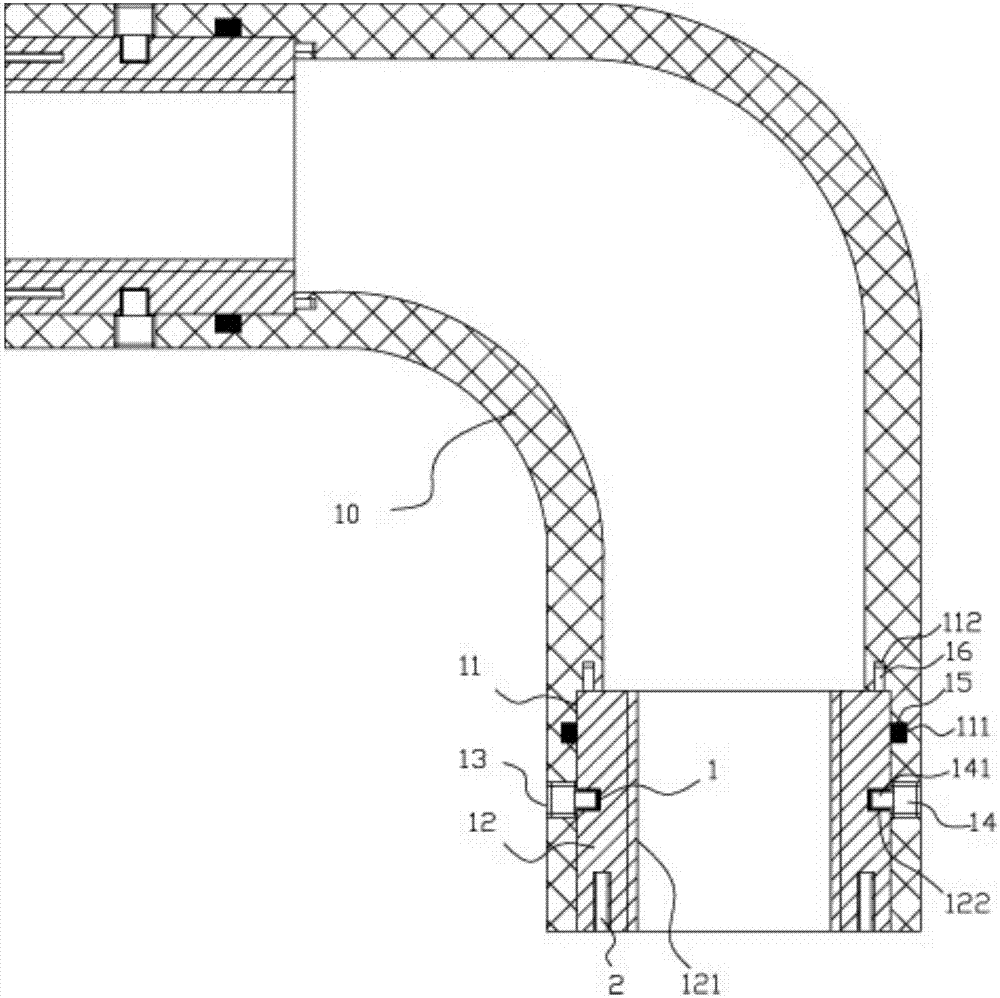

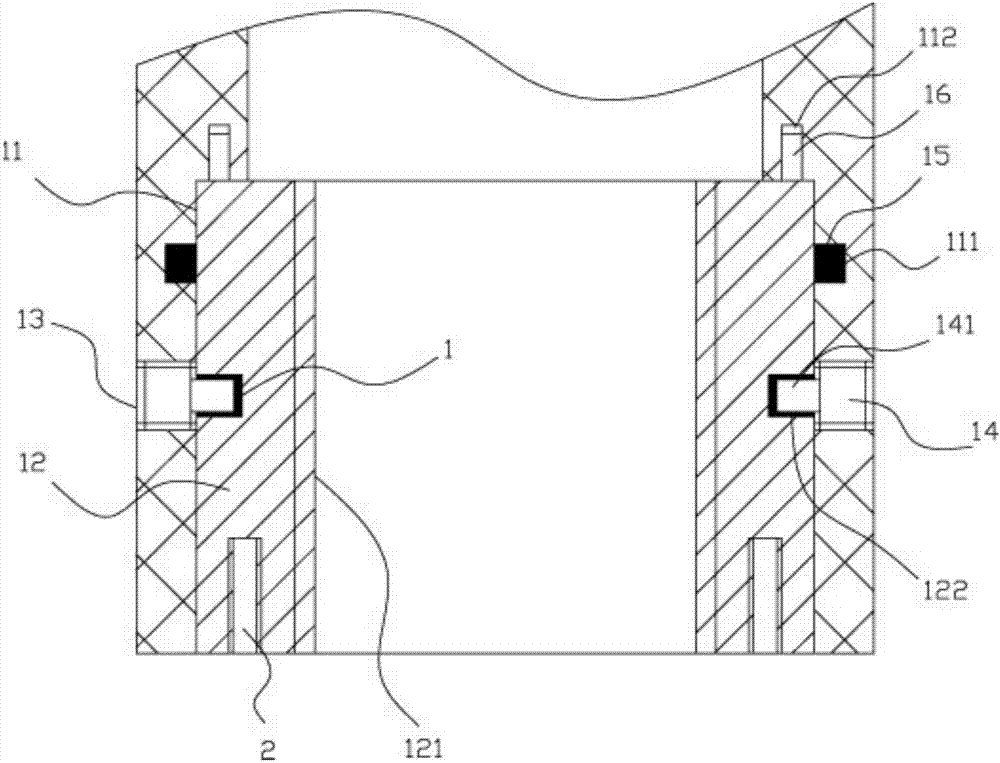

[0020] Example: see Figure 1 to Figure 2 As shown, an elbow pipe fitting includes an elbow main body 10, an annular groove 11 is formed on the inner side walls of the two joints of the elbow main body 10, and a connecting sleeve 12 is inserted into the corresponding elbow main body 10. In the connector, the outside of the connecting sleeve 12 is inserted into the corresponding annular groove 11, the outer wall of the connecting sleeve 12 is pressed against the inner wall of the annular groove 11, and the inner wall of the connecting sleeve 12 has an internal thread 121;

[0021] There are a plurality of screw holes 13 on the outer wall of the connector of the elbow main body 10, the screw holes 13 correspond to the positioning concave holes 122 on the outer wall of the connecting sleeve 12, and the positioning block 14 is screwed. In the threaded through hole 13 , the end of the positioning block 14 has a protruding portion 141 , and the protruding portion 141 is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com