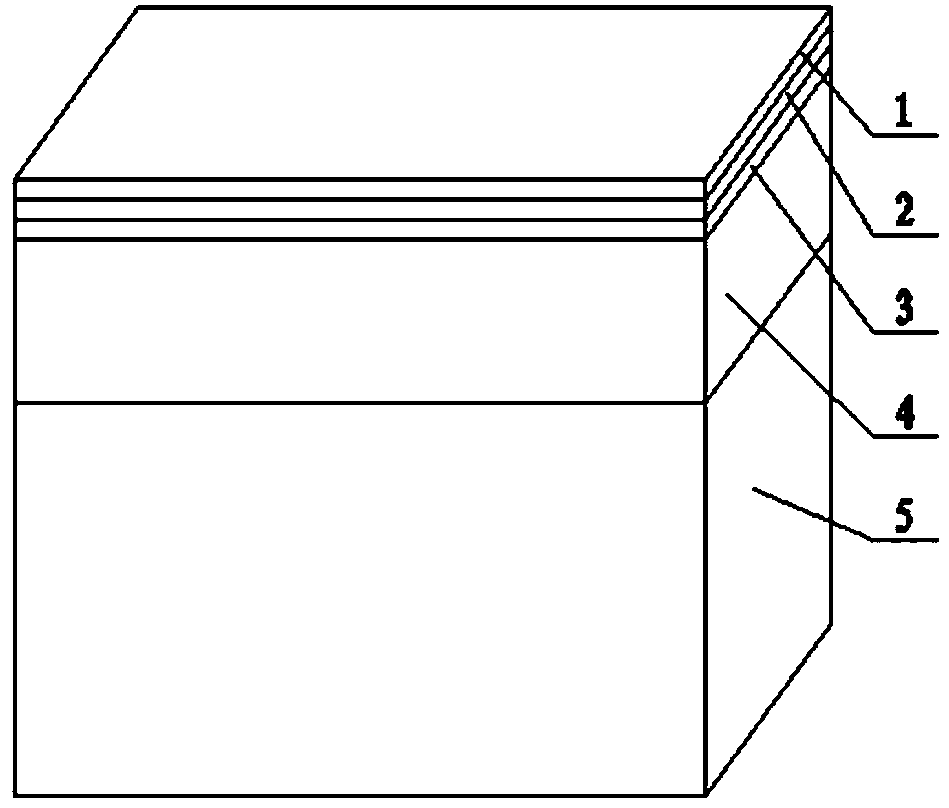

Manufacturing method of color concrete granite flamed-surface terrace

A technology of colored concrete and a manufacturing method, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of affecting the geological environment, high cost, large loss, etc., and achieve the effect of improving easy falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with the best embodiment 。

[0027] The manufacturing method of the colored concrete granite fire surface floor comprises the following steps:

[0028] (1) Formwork support: Formwork support is carried out on the road section to be constructed; this formwork is divided into side formwork and inner formwork; the formwork is made of rectangular tubes or wooden strips with the same specifications. Mold requirements: straight, long and short, and consistent in height. The height can be ordered according to the construction requirements.

[0029] (2) Concrete pouring: pour the concrete evenly within the range of the formwork;

[0030] The concrete raw materials include: the weight ratio of strengthening agent raw materials is; (take one ton of strengthening agent as an example) high-strength cement: 600, quartz sand: 400, (diameter of quartz sand is 0.5~1mm) silicon powder: 8, Nai It is a water reducing agent: 3. Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com