Machining process of axial-flow type turbine blade

A technology for steam turbine blades and processing technology, applied in the field of steam turbine blades, can solve problems such as unstable product quality, unreasonable processing methods, and backward processing technology, and achieve the effects of improving product quality, preventing processing errors, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

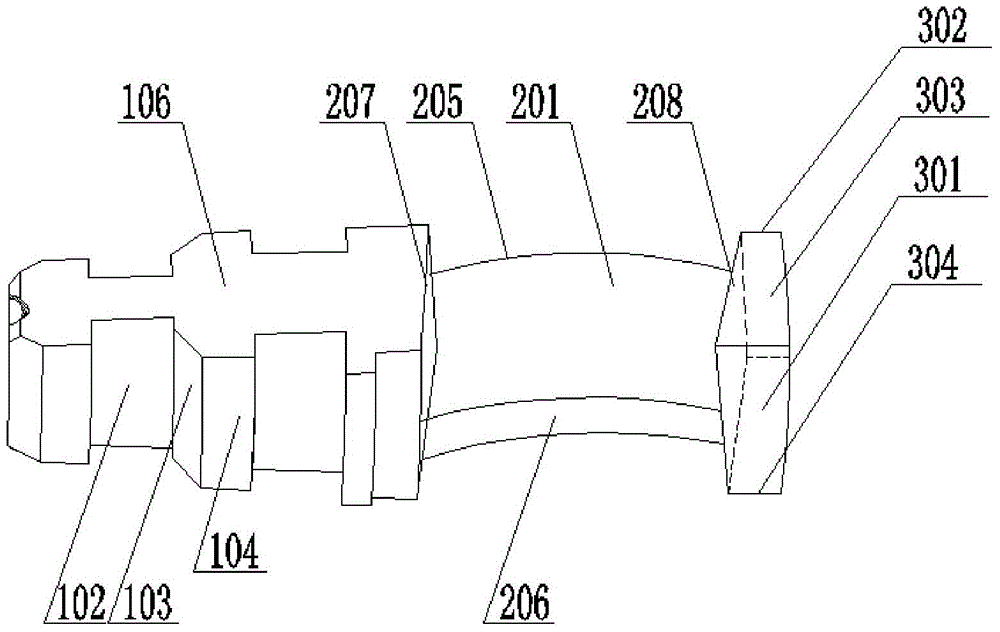

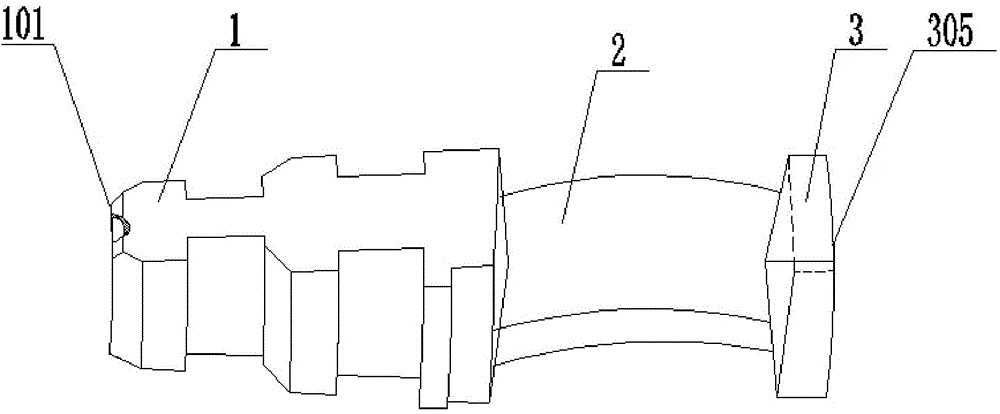

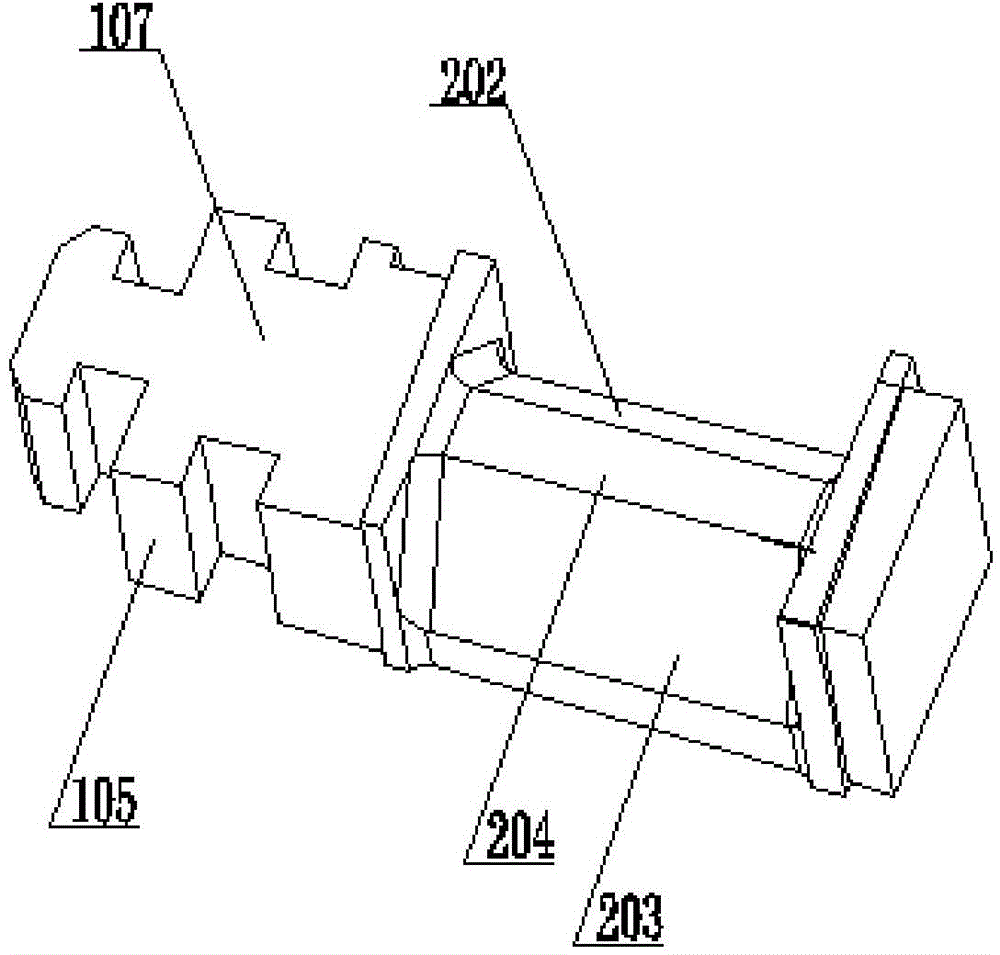

[0023] The processing technology of a kind of axial-flow steam turbine blade provided in this embodiment, the steam turbine blade includes three parts of blade root 1, blade shape 2 and blade crown 3 successively along its length direction, and the processing technology of steam turbine blade is processed according to the following steps:

[0024] Step (1): first pass the rough square material through the ordinary milling machine and use the end milling cutter to process the two sides through the two processes of rough milling and fine milling, and then process the other two sides with the two sides processed first as the reference plane. side, and then use the end mill to process both ends, one end is the blade root end 101, and the other end is the blade crown end 305;

[0025] Step (2): After the two processes of rough milling and fine milling on one side, first process the steam outlet side and mark "C" on the end face of the blade root close to the steam outlet side, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com