Technique for producing new energy by using firewood, grass and straws to treat CO2 in blast furnace tail gas

A technology of blast furnace tail gas and technology, which is applied in the technical field of using firewood, grass and straw to process CO2 in blast furnace tail gas to produce new energy, can solve problems such as waste, achieve low environmental pollution, high gas production rate, and reduce energy shortage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

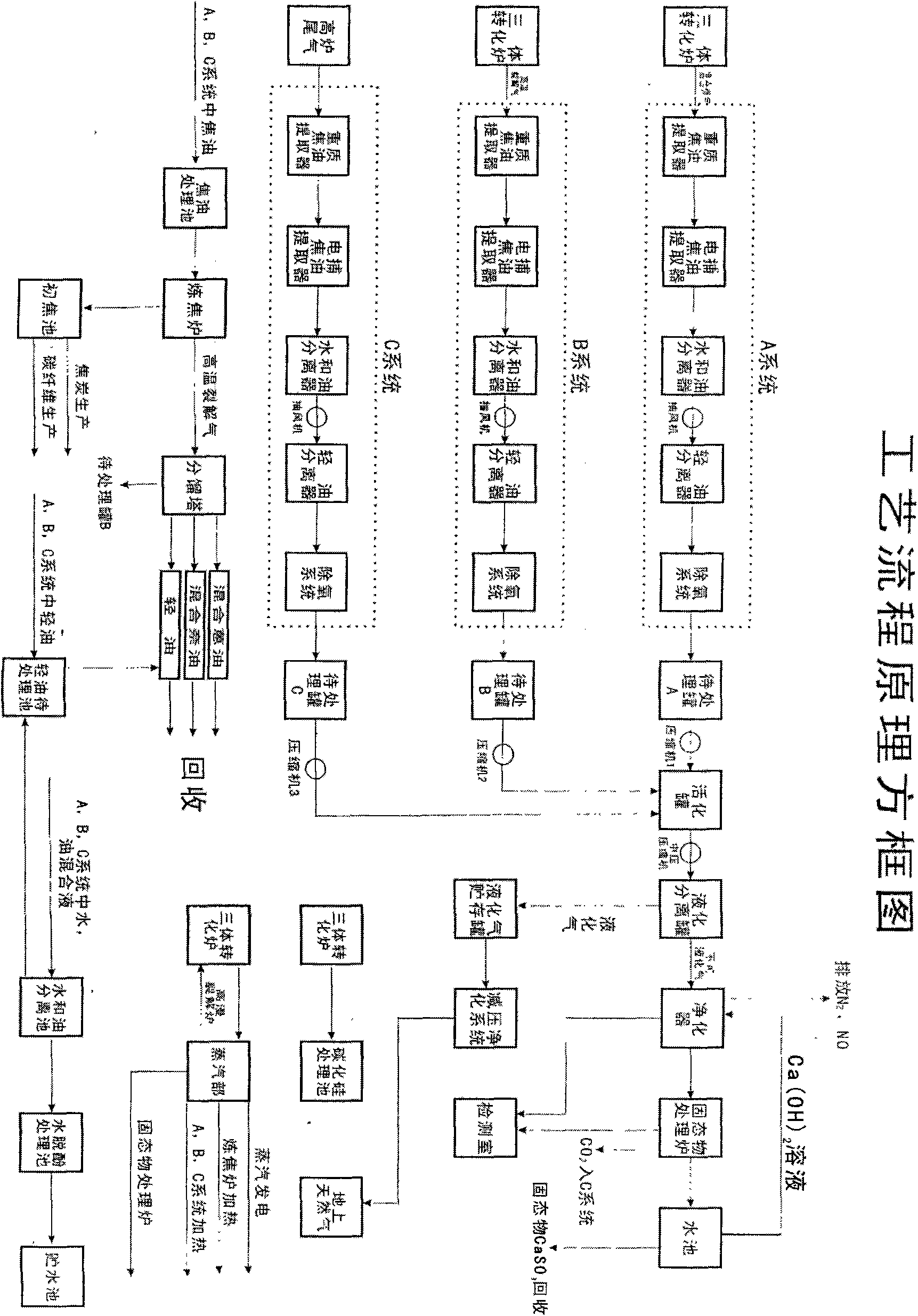

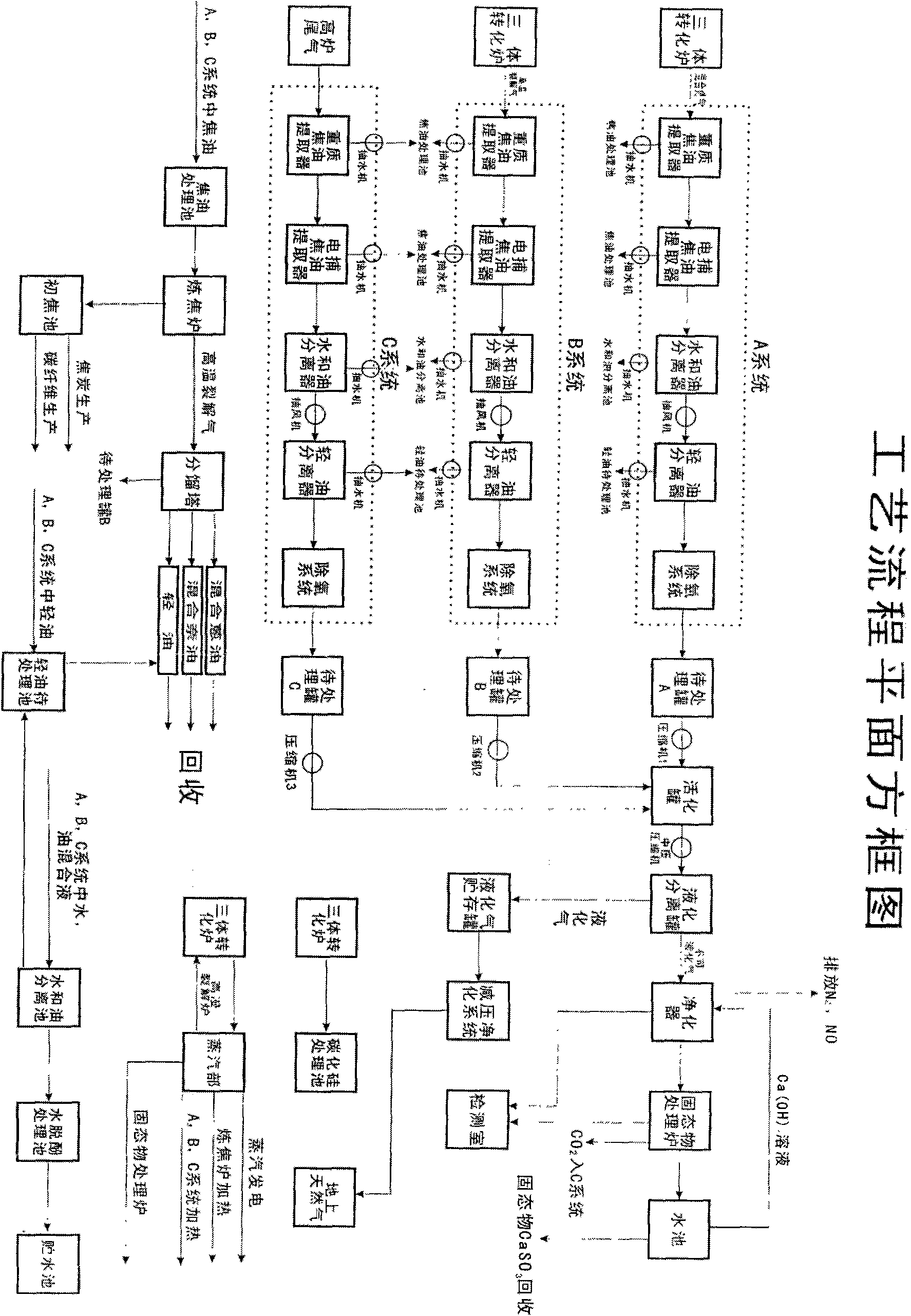

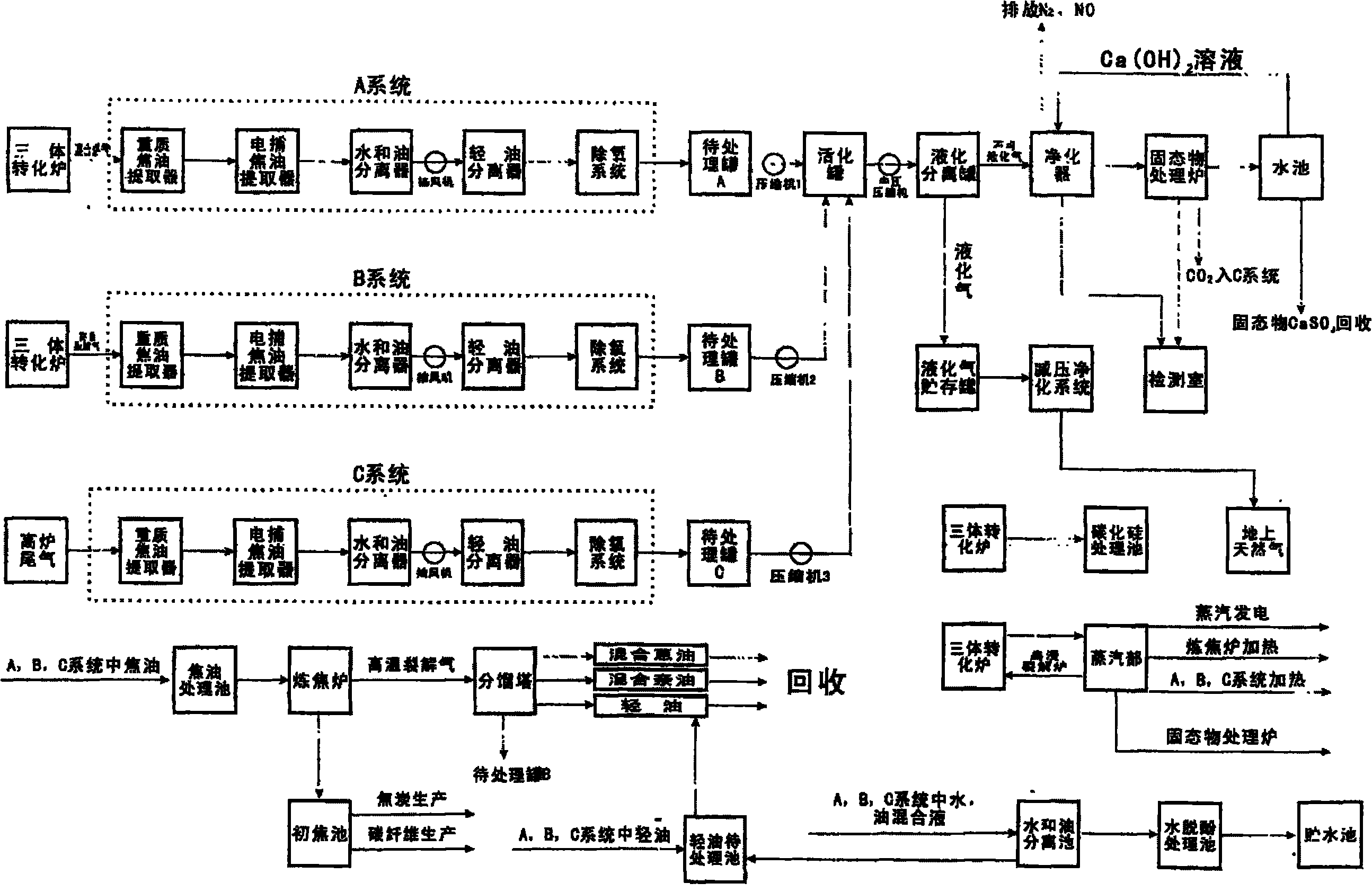

[0039] The present invention will be further described below in conjunction with accompanying drawing:

[0040] As shown in Figures 1 and 2, the CO in blast furnace tail gas is treated with firewood, grass and straw 2 New energy production technology, the process steps are as follows:

[0041] (1) Firewood, grass and stalks are sent into the three-body conversion furnace, and mixed gas is produced by the combustion furnace respectively in a closed state, the high-temperature cracking furnace produces high-temperature cracking gas, carbon and silicon carbide, and the steam furnace produces steam;

[0042] (2) The mixed gas produced in step (1) is fed into system A, and is extracted and separated from heavy tar, electric tar extractor, water and oil separator, and light oil separator respectively through heavy tar extractor, electric tar extractor, After capturing tar, water and oil mixture, and light oil, the tail gas is sent to the deoxygenation system for deoxygenation and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com