Waterproof material manufacturing technology for building construction

A waterproof material and building construction technology, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of loss, maintenance, and the long time required for dismantling and replacing rollers, which affect the production of steel plate waterstops Efficiency and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

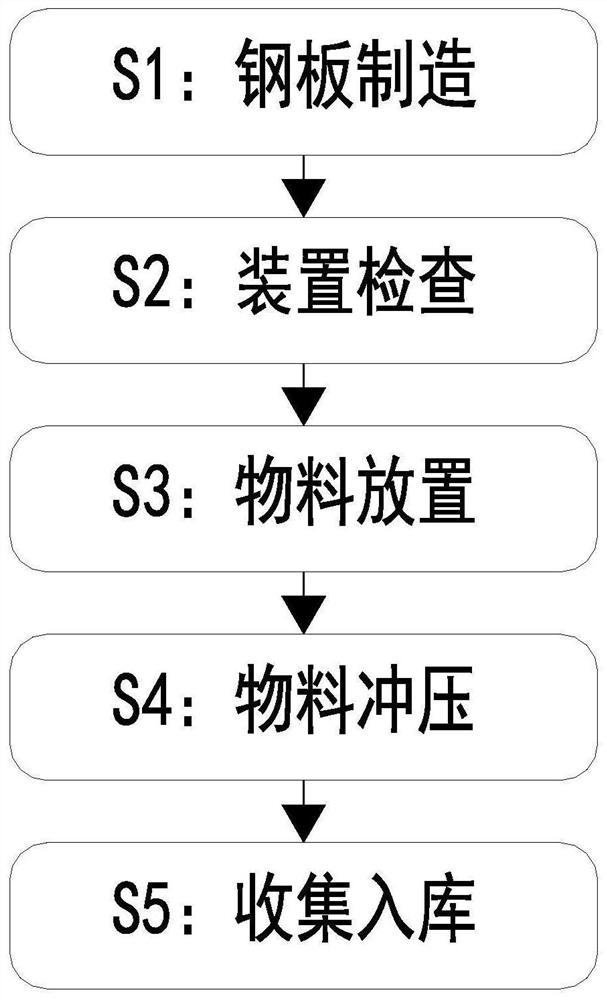

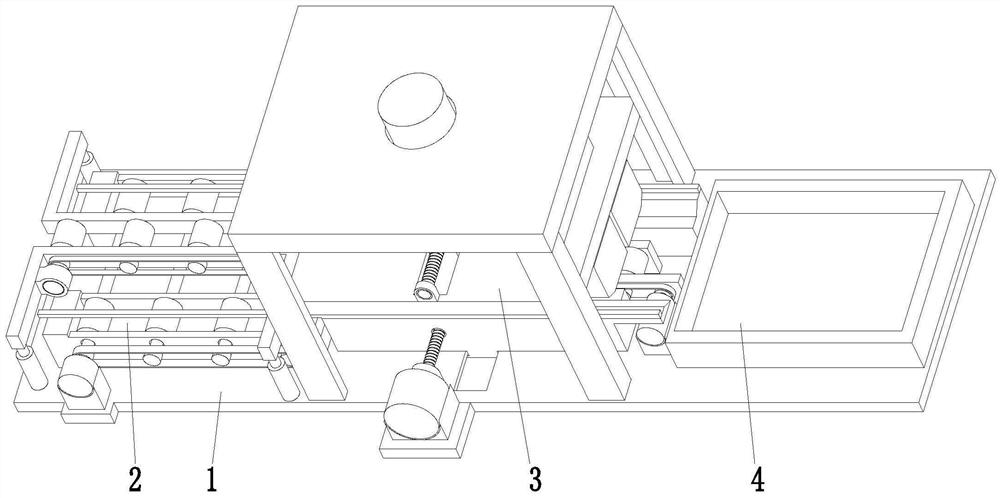

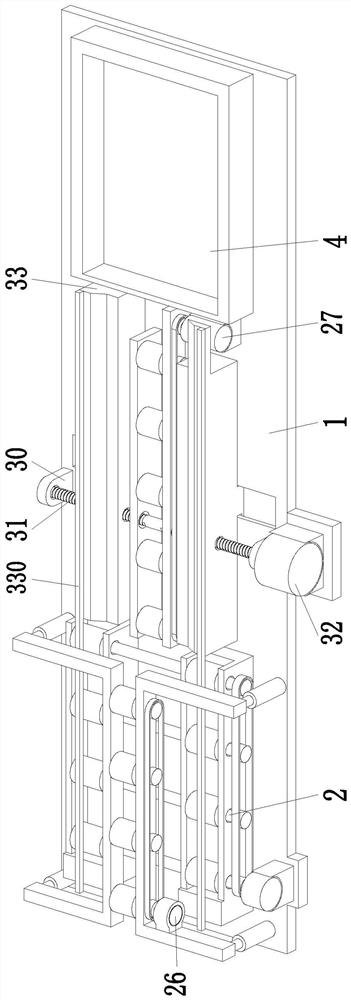

[0035] Such as Figure 1 to Figure 8 As shown, a manufacturing process of waterproof material for building construction, the manufacturing process of waterproof material for building construction adopts the following manufacturing device for waterproof material for building construction, the manufacturing device for waterproof material for building construction includes a base 1, a transmission mechanism 2, a stamping mechanism 3 and a receiving box 4. A transmission mechanism 2, a stamping mechanism 3 and a receiving box 4 are arranged on the upper surface of the base 1 from left to right;

[0036] During specific work, the present invention can punch steel plates of different widths into steel plate waterstops; first, the steel plates are inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com