Metal recycling process and recycling device for waste abs plastic electroplating parts

A technology of ABS plastic and electroplating parts, which is applied in the field of waste resource recycling technology, can solve the problem of low application value of copper sulfide, and achieve the effect of increasing application value, reducing production cost, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

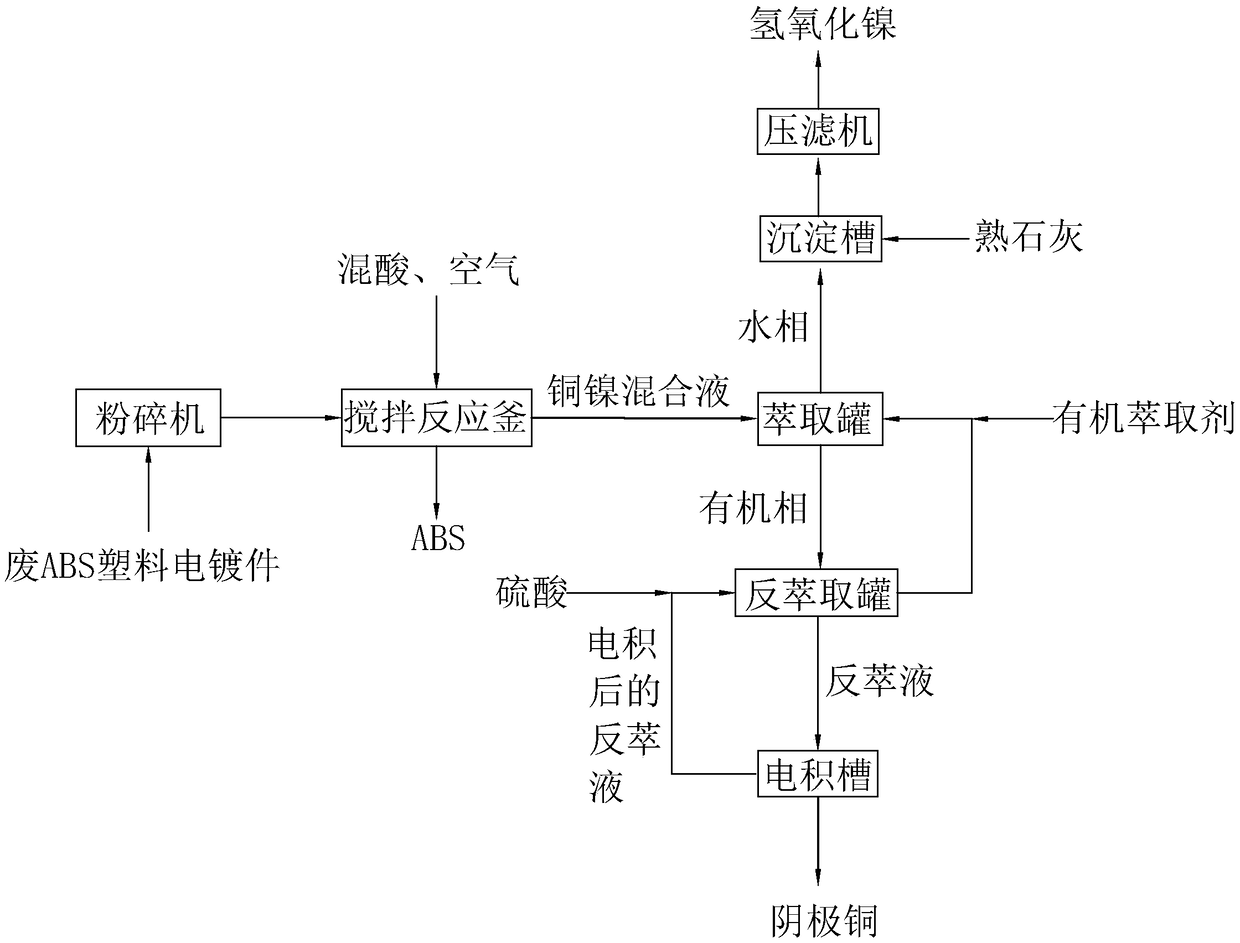

[0042] A metal recycling process for waste ABS plastic electroplating parts, comprising the steps of:

[0043] Step1: Crushing waste ABS plastic electroplating parts;

[0044] Step2: Add mixed acid to the broken waste ABS plastic electroplating parts, pass air to react for 3 hours, choose to pass hot air or direct air according to the reaction temperature to control the reaction temperature at 60 ° C, according to the weight ratio, waste ABS plastic electroplating parts : mixed acid=2: 3, mixed acid comprises hydrochloric acid and sulfuric acid, the massfraction of hydrochloric acid is 5%, the massfraction of sulfuric acid is 15%, and hydrochloric acid and sulfuric acid mass ratio are 1: 1;

[0045] Step3: After the reaction is over, press filter to obtain the copper-nickel mixture, add an organic extractant to the copper-nickel mixture, and separate;

[0046] Step4: The organic phase is back-extracted with sulfuric acid with a mass fraction of 40%, and cathode copper is form...

Embodiment 2

[0050] A metal recycling process for waste ABS plastic electroplating parts, comprising the steps of:

[0051] Step1: Crushing waste ABS plastic electroplating parts;

[0052] Step2: Add mixed acid to the broken waste ABS plastic electroplating parts, and pass air to react for 4 hours. According to the reaction temperature, choose to pass hot air or direct air to control the reaction temperature to 62 ° C. According to the weight ratio, waste ABS plastic electroplating parts : mixed acid=2:3, mixed acid comprises hydrochloric acid and sulfuric acid, the massfraction of hydrochloric acid is 8%, the massfraction of sulfuric acid is 10%, and the mass ratio of hydrochloric acid and sulfuric acid is 1:1;

[0053] Step3: After the reaction is over, press filter to obtain the copper-nickel mixture, add an organic extractant to the copper-nickel mixture, and separate;

[0054] Step4: The organic phase is back-extracted with sulfuric acid with a mass fraction of 40%, and cathode coppe...

Embodiment 3

[0058] A metal recycling process for waste ABS plastic electroplating parts, comprising the steps of:

[0059] Step1: Crushing waste ABS plastic electroplating parts;

[0060] Step2: Add mixed acid to the broken waste ABS plastic electroplating parts, and pass air to react for 3 hours. According to the reaction temperature, choose to pass hot air or direct air to control the reaction temperature to 64 ° C. According to the weight ratio, waste ABS plastic electroplating parts : mixed acid=2:3, mixed acid comprises hydrochloric acid and sulfuric acid, the massfraction of hydrochloric acid is 10%, the massfraction of sulfuric acid is 12%, and the mass ratio of hydrochloric acid and sulfuric acid is 1:1;

[0061] Step3: After the reaction is over, press filter to obtain the copper-nickel mixture, add an organic extractant to the copper-nickel mixture, and separate;

[0062] Step4: The organic phase is back-extracted with sulfuric acid with a mass fraction of 40%, and cathode copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com