Unified control method and system for bar code printing equipment

A barcode printing and equipment control technology, applied in the field of information management, can solve problems such as increasing the workload of developers, affecting product production efficiency, prolonging the development cycle of barcode printing applications, etc., and achieving the effect of shortening the development cycle and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

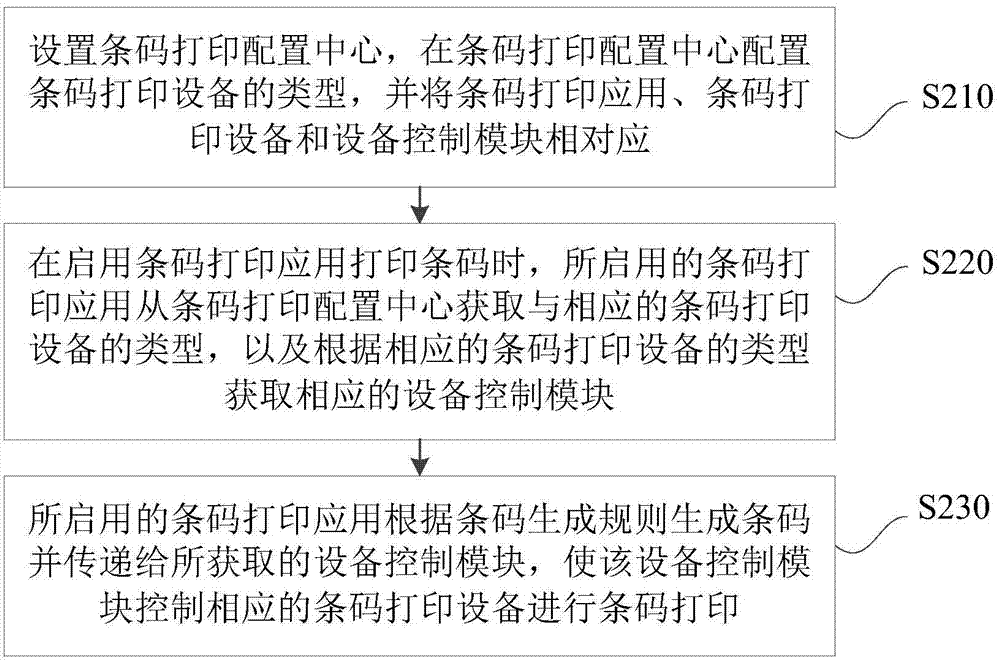

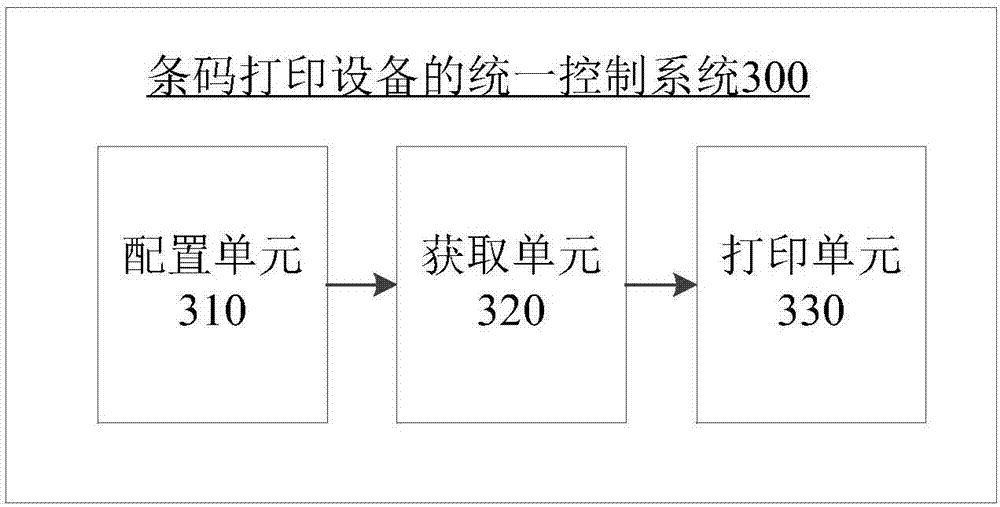

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

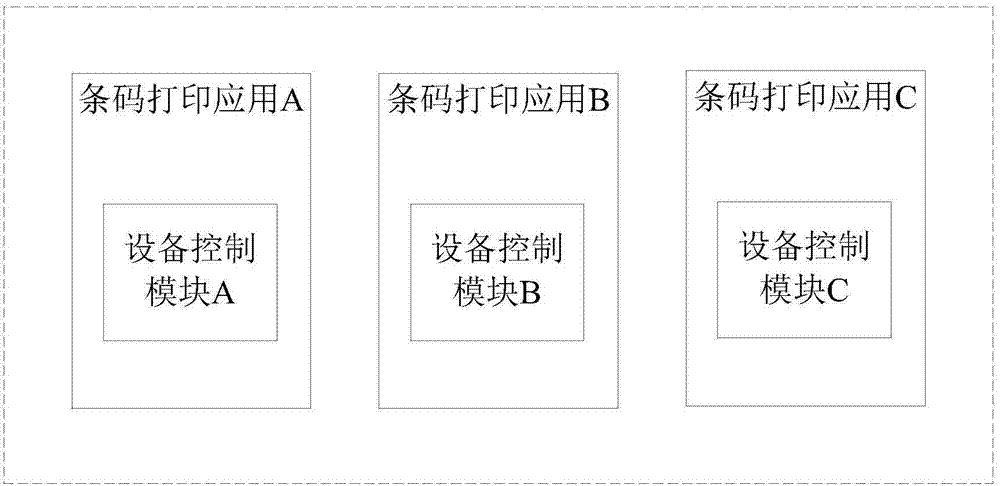

[0025] Aiming at the problem that the aforementioned traditional barcode printing application has a long development cycle and is not easy to transplant, the present invention separates the control module that controls the barcode printing device from the barcode printing application, so that when the barcode printing application is enabled to print barcodes, the barcode printing device can be controlled The control module is not affected by equipment replacement or barcode marking, which can reduce the workload of developers, shorten the development cycle, and at the same time make the production efficiency of products not affected by barcode marking.

[0026] Before introducing the present invention, some concepts involved in the present invention will be explained first.

[0027] Barcode printing application: that is, barcode printing softw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com