Corrugated pipe processing method

A processing method and technology for corrugated pipes, applied in the field of corrugated pipe processing, can solve the problems of melting of corrugated pipe incisions, increase of temperature at the incision of corrugated pipes, affecting the production quality of corrugated pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to achieve the above object, the present invention adopts the following technical solutions: a bellows processing method, the processing method comprising:

[0028] a. Stirring and mixing: Add polyethylene plastic and foaming agent into the mixing drum for stirring and mixing;

[0029] b. Dissolution: Put the stirred and mixed raw materials into the extruder for dissolution;

[0030] c. Molding: Put the dissolved raw materials into the mold for solidification and molding;

[0031] d. Rinse: use cold water to rinse the formed bellows;

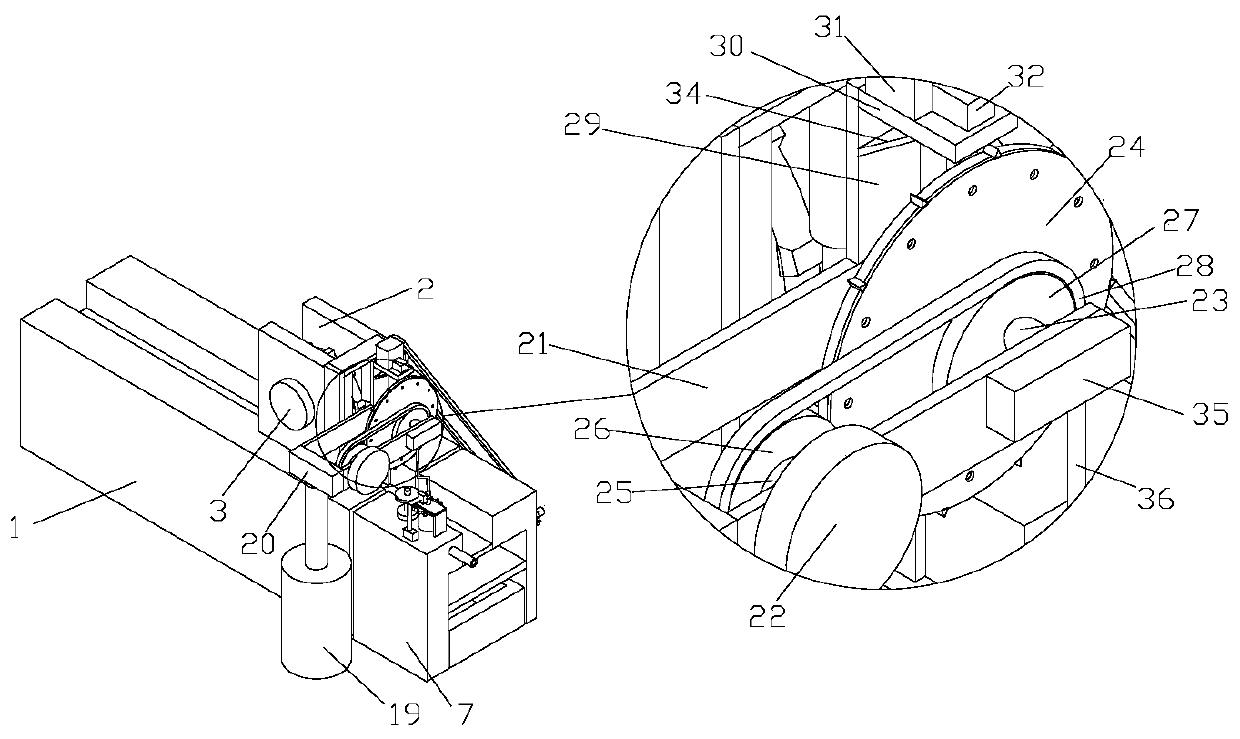

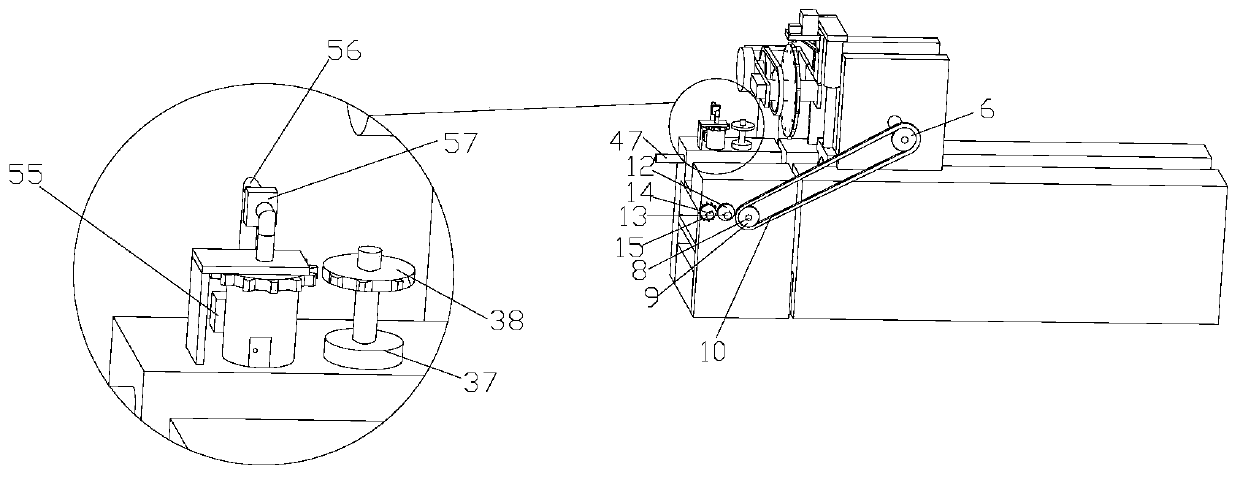

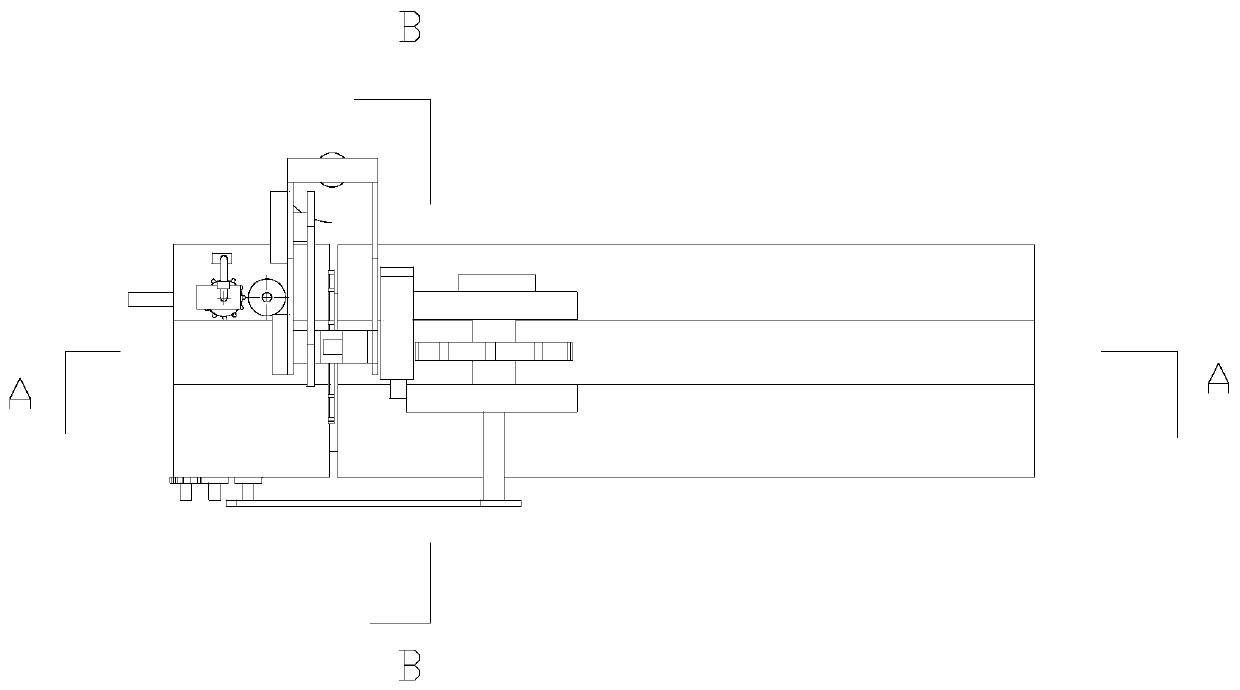

[0032] e. Cutting: use bellows cutting equipment to cut the washed bellows;

[0033] The dissolving operation is to put the raw material into the extruder, raise the temperature in the extruder to 230° C., and then extrude it from the extruder to form a molten state.

[0034] The flushing operation is to place the formed bellows in the fountain for flushing with water, and move the bellows back and forth under the nozzle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com