Method and device for preparing fluorinated graphene and high purity lithium fluoride as by-product

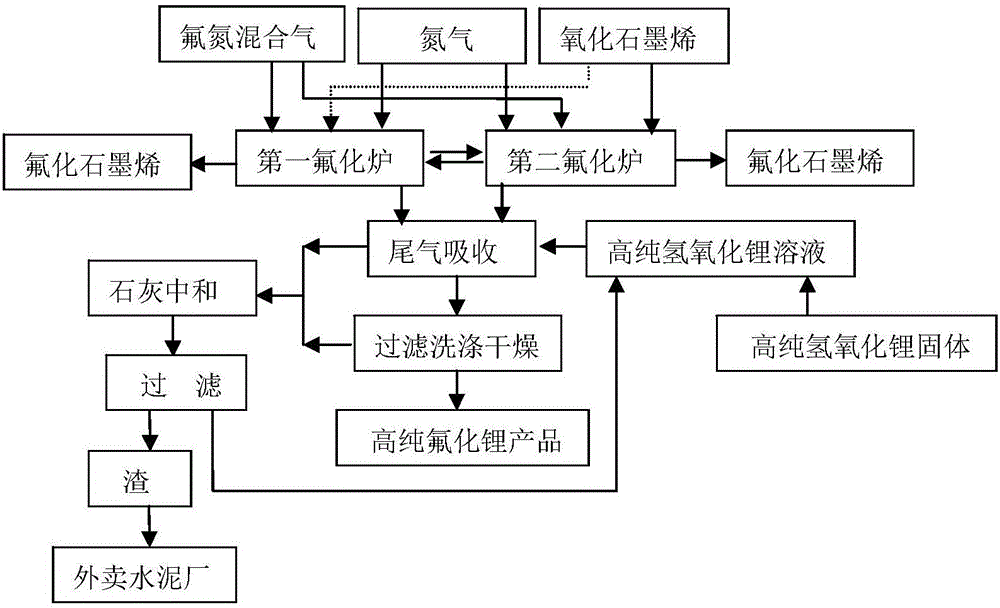

A technology of high-purity lithium fluoride and fluorinated graphene is applied to the equipment for preparing fluorinated graphene by-product high-purity lithium fluoride, and the field of preparing high-purity lithium fluoride by-product of graphene fluoride can solve the waste of resources , the problem of low utilization of raw materials, etc., to achieve the effect of improving utilization, good economic and environmental benefits, and high fluorination uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

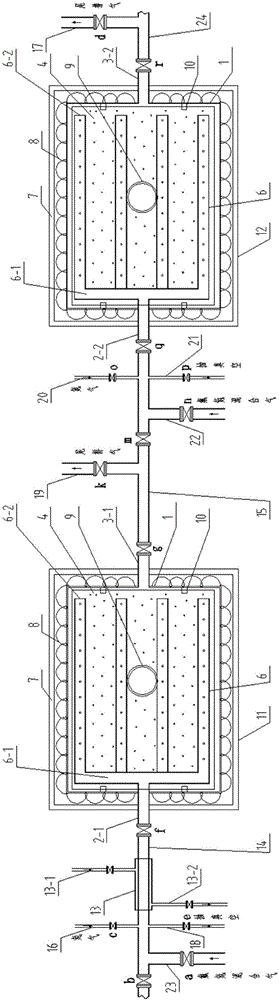

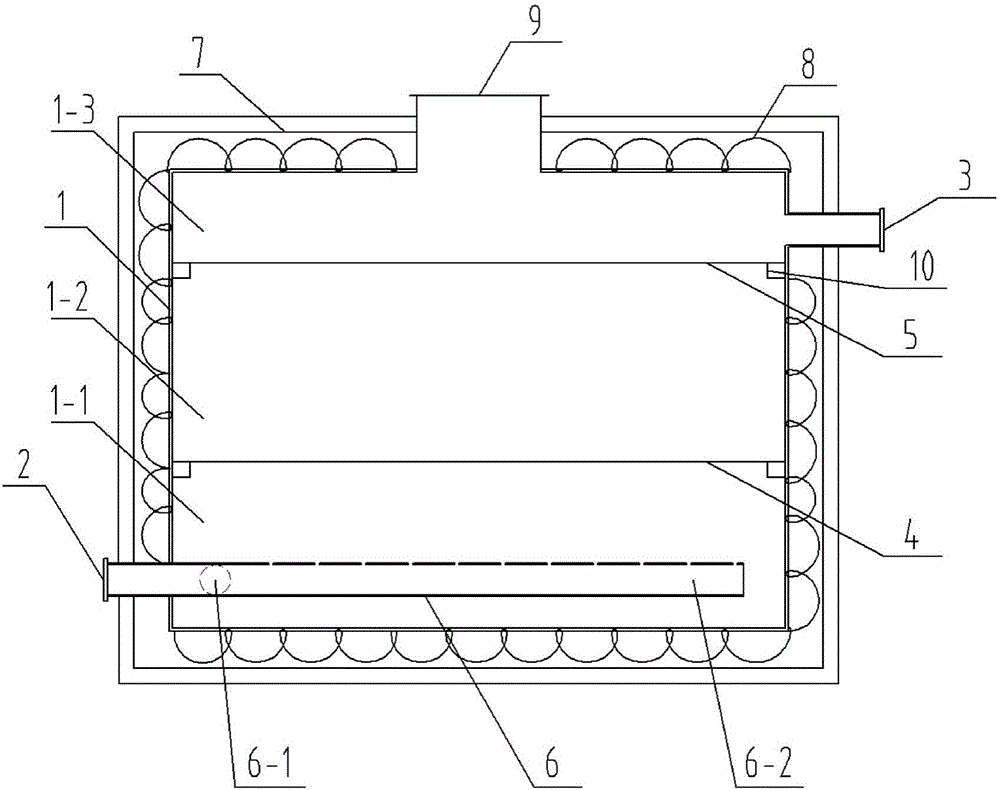

[0051] In the equipment of described preparation fluorinated graphene by-product high-purity lithium fluoride (as figure 1 shown), the gas inlet 3-1 of the first fluorination furnace 11 is connected with an inlet pipeline 14, and the inlet pipeline 14 is sequentially provided with a valve b and a valve f along the direction close to the first fluorination furnace 11 , the inlet pipeline 14 between the valve b and the valve f is connected with a fluorine-containing gas supply pipeline 23, a nitrogen gas supply pipeline 16 and a vacuuming pipeline 18, and the fluorine-containing gas supply pipeline 23 is provided with a valve a, which contains fluorine The gas supply pipeline 23 is connected with the gas source of the fluorine-containing gas (preferred fluorine-nitrogen mixed gas); the nitrogen gas supply pipeline 16 (connected with the nitrogen gas source) is provided with a valve c; the vacuum pipeline 18 is provided with a valve e, and the vacuum tube The road 18 is connected...

Embodiment 1

[0071] The method for preparing fluorinated graphene by-product high-purity lithium fluoride of the present embodiment comprises the following steps:

[0072] 1) Place four parts of graphene oxide with a weight of 10kg in four nickel arks, spread evenly, control the thickness of the material at 2.5mm, and cover the material with a nickel alloy wire mesh;

[0073] 2) Place the above-mentioned four parts of materials together with the ark and the silk screen in the reaction chambers of the first fluorination furnace and the second fluorination furnace, and seal the fluorination furnace;

[0074] 3) The fluorination furnace starts to heat up, turn on the cooling water circulation device, and at the same time turn on the vacuum pump, adjust the valve to evacuate the fluorination furnace until the pressure in the furnace is 0.04MPa; when the temperature rises to 300°C, heat at a constant temperature for 1.5h to keep the temperature constant cleaning;

[0075] 4) After removing imp...

Embodiment 2

[0087] The method for preparing fluorinated graphene by-product high-purity lithium fluoride of the present embodiment comprises the following steps:

[0088] 1) Place four parts of graphene oxide with a weight of 10kg in four Hastelloy arks, spread evenly, control the thickness of the material at 2mm, and cover the material with a Hastelloy wire mesh;

[0089] 2) Place the above-mentioned four parts of materials together with the ark and the silk screen in the reaction chambers of the first fluorination furnace and the second fluorination furnace, and seal the fluorination furnace;

[0090] 3) The fluorination furnace starts to heat up, turn on the cooling water circulation device, and at the same time turn on the vacuum pump, adjust the valve to evacuate the fluorination furnace until the pressure in the furnace is 0.035MPa; miscellaneous;

[0091] 4) After removing impurities at constant temperature, control the source pressure of fluorine-nitrogen mixed gas to 0.2MPa, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com