3d direct writing zirconia ceramic ink

A technology of zirconia ceramics and zirconia particles, which is applied in the field of 3D printing materials, can solve the problems of complicated follow-up processing, low forming precision, low forming strength, etc., and achieves free adjustment of porosity and stent width, good elastic performance and strength, Avoid cracking or deforming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

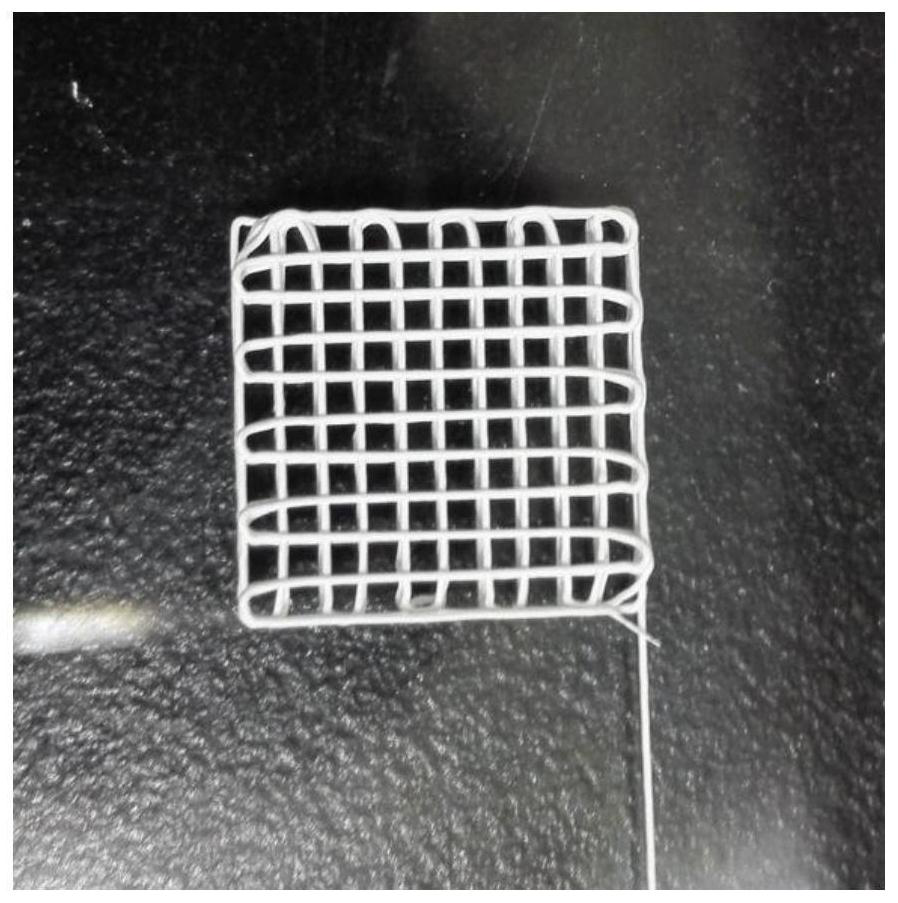

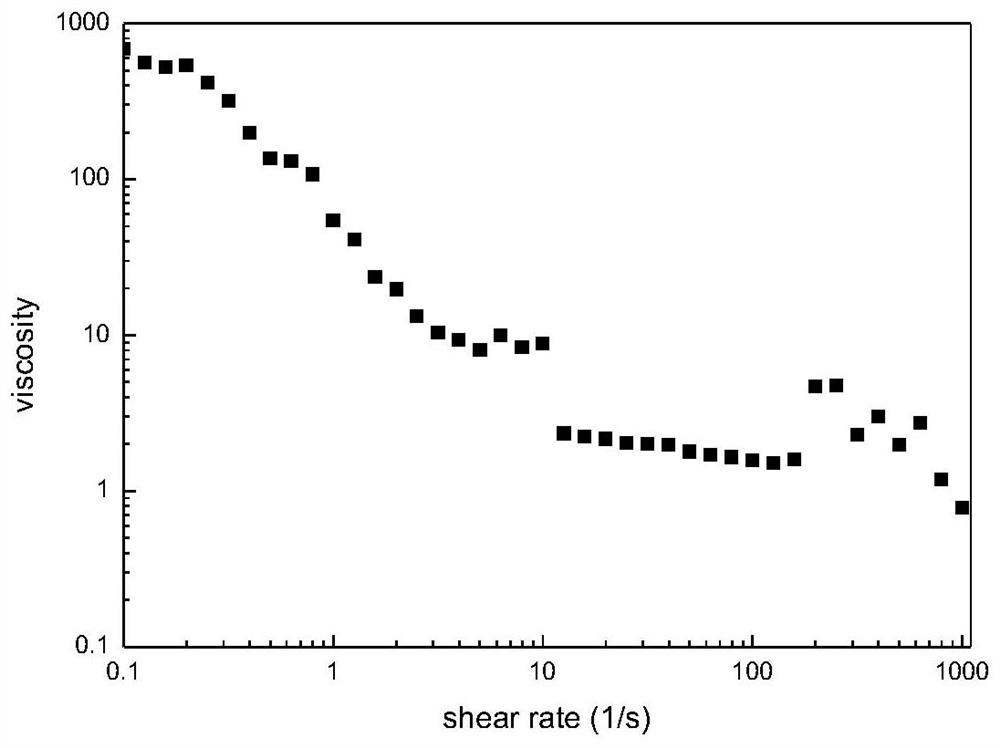

[0047] Zirconia particles (preferably particle size D 50 =0.8um), deionized water, cellulose, polyvinyl acid, and ammonium chloride are mixed to form a slurry; the solid phase content of zirconia is 44%, the cellulose content is 0.002g / ml, and polyvinyl acid is a dry powder of zirconia particles content of 0.6%, and the amount of ammonium chloride is 0.06% of the ink mass. After mixing the above materials in proportion, they are placed on a ball mill and milled at a speed of 90rmp for 12 hours to obtain zirconia ceramic ink. The zirconia ceramic ink has very good Shear thinning, which in 10s -1 The viscosity at the shear rate is 2Pa·s, and it has very good viscoelasticity, and its elastic modulus at 1pa is as high as 10 3 Pa, has good shape retention, can pass through the needle nozzle blockage smoothly and maintain a three-dimensional shape, then put the ink into the spray barrel of the 3D direct writing device, the nozzle diameter is 100um, set the program of the 3D direct ...

Embodiment 2

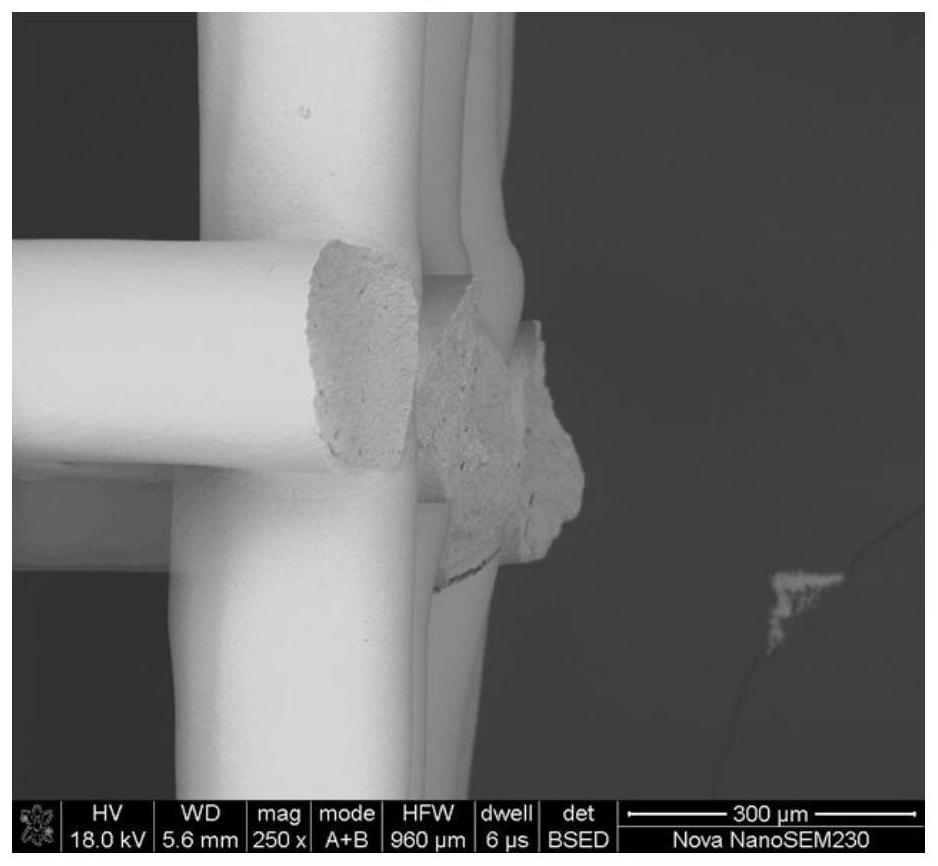

[0049] 1 μm zirconia particles, deionized water, zinc acetate, hydantoin epoxy resin, ammonium polyacrylate; in the slurry: zirconia solid phase content ranges from 56vol%, hydantoin epoxy resin with a content of 15wt%, ammonium polyacrylate The content of dry powder of zirconia particles is 0.8%, and the dosage of zinc acetate is 0.05% of the ink mass. Mix the above materials in proportion and put them on a ball mill at a speed of 100-140rmp for 12-24h, remove them, and ultrasonically oscillate for 1-12h Then get 3D direct writing zirconia ceramic ink. its in 10s -1 The viscosity at the shear rate is 3Pa·s, and it has very good viscoelasticity, and its elastic modulus at 10pa is as high as 10 3 Pa, has good shape retention, can pass through the nozzle plug smoothly and maintain a three-dimensional shape, (see Figure 5-6 )

[0050] The 3D direct writing zirconia ceramic ink is loaded into the spray barrel of the 3D direct writing device, the nozzle diameter is 2um, the pro...

Embodiment 3

[0052] Mix 0.5 μm zirconia particles, deionized water, gum arabic, sodium polycarboxylate, and sodium chloride evenly, the solid phase content of zirconia is 40vol%, the gum arabic content is 0.08g / ml, sodium polycarboxylate The salt is 1% of the dry powder content of zirconia particles, and the amount of sodium chloride is 0.1% of the ink mass. The above materials are mixed in proportion and placed on a ball mill at a speed of 100-140rmp for 12-24h, removed, and ultrasonically oscillated for 1 After -12h, the 3D direct writing zirconia ceramic ink is obtained. its in 10s -1 The viscosity at the shear rate is 2Pa·s, and has very good viscoelasticity, and its elastic modulus at 0.5pa is as high as 10 3 Pa, has good shape retention, can pass through the nozzle plug smoothly and maintain a three-dimensional shape, (see Figure 7-8 )

[0053] The 3D direct writing zirconia ceramic ink is loaded into the spray barrel of the 3D direct writing device, the nozzle diameter is 10um, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com