High silicon Y-type zeolite containing rare-earth and its preparing method

A zeolite and rare earth technology, which is applied in the directions of crystalline aluminosilicate zeolite and octahedral crystalline aluminum silicate zeolite, etc. problems, to achieve the effects of high structural stability and hydrothermal stability, easy large-scale industrial application, and uniform contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]According to the preparation method of the zeolite provided by the present invention, the silicon-aluminum ratio of the rare earth-containing Y-type zeolite is 3-8, preferably 4-6; and the unit cell constant is 2.45-2.48 nanometers. In terms of rare earth oxides, the rare earth content in the rare earth-containing Y-type zeolite is greater than zero to 20% by weight, preferably 6-18% by weight. The rare earth-containing Y-type zeolite can be obtained commercially, or can be prepared from NaY zeolite with a unit cell constant of 2.45-2.48 nanometers by means of rare earth ion exchange. If using the NaY zeolite and rare earth chloride aqueous solution according to NaY:RECl 3 :H 2 The weight ratio of O=1:0.1-0.25:5-15, under the conditions of pH>3.5 and temperature 80-95°C, perform rare earth ion exchange at least once, each exchange for 30-60 minutes, wash and dry after exchange to obtain . The method of preparing rare earth-containing Y-type zeolite from NaY zeolite th...

Embodiment approach 1

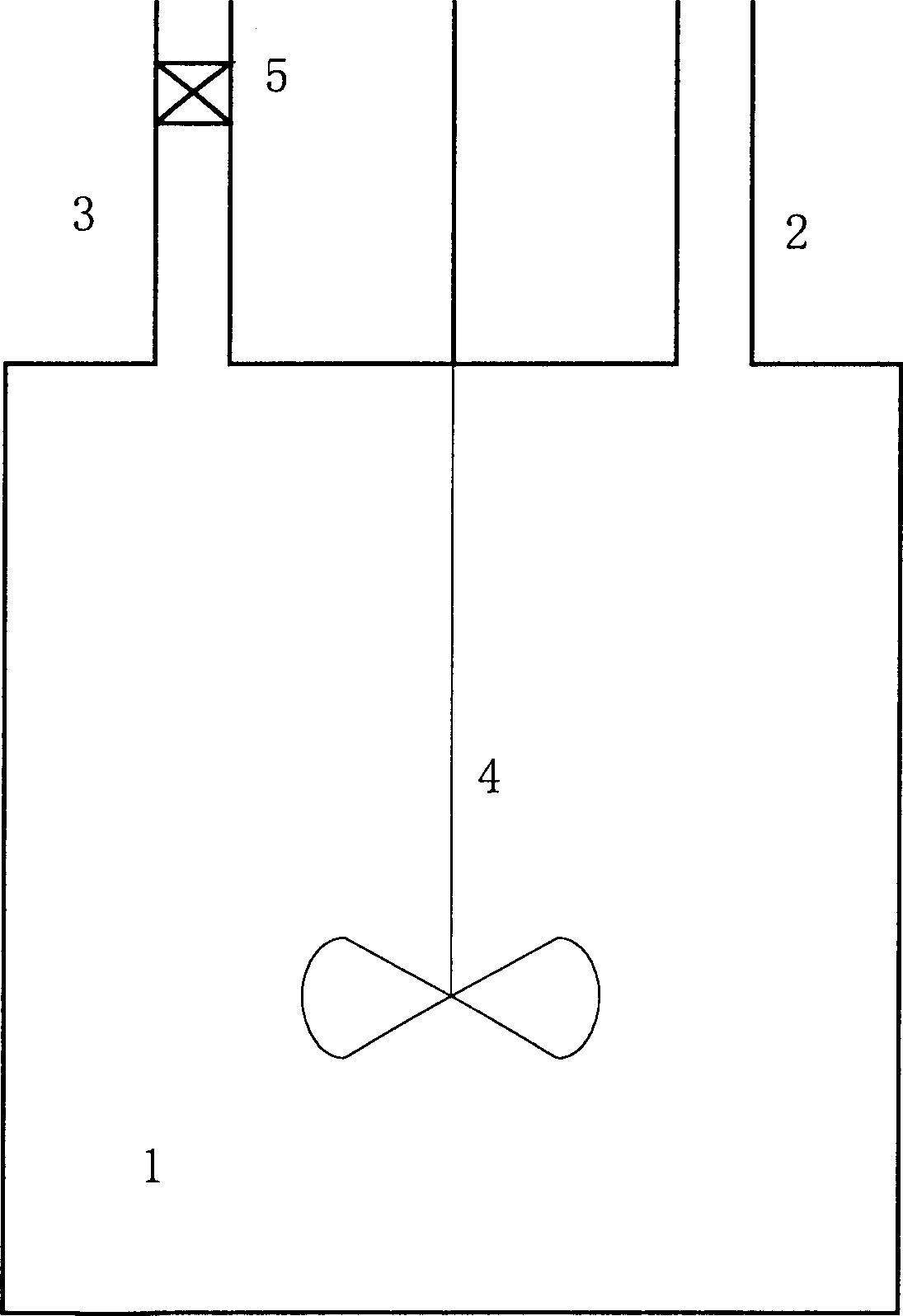

[0029] The first specific embodiment of the present invention is as follows figure 1 shown. Described reaction equipment comprises a reactor 1, a feed port 2 and a gas outlet 3, also has a stirrer 4 inside the reactor 1, and wherein, a gas-solid separator 5 is installed on the gas outlet 3, gas The hole diameter and porosity of the holes contained in the solid separator 5 ensure that the gas can pass through but the solid particles cannot pass through. The stirring rod of the stirrer 4 stretches out of the reaction kettle 1, and the place where the stirring rod contacts the reaction kettle 1 is airtight, so that the reaction kettle 1 is not connected to the outside world.

[0030] When preparing the zeolite provided by the present invention, the rare earth-containing Y-type zeolite solid particles are loaded from the feed port 2, the agitator 4 is started, and silicon tetrachloride liquid is added, and the feed port 2 and the gas outlet 3 are sealed. Heat the reaction kettl...

Embodiment approach 2

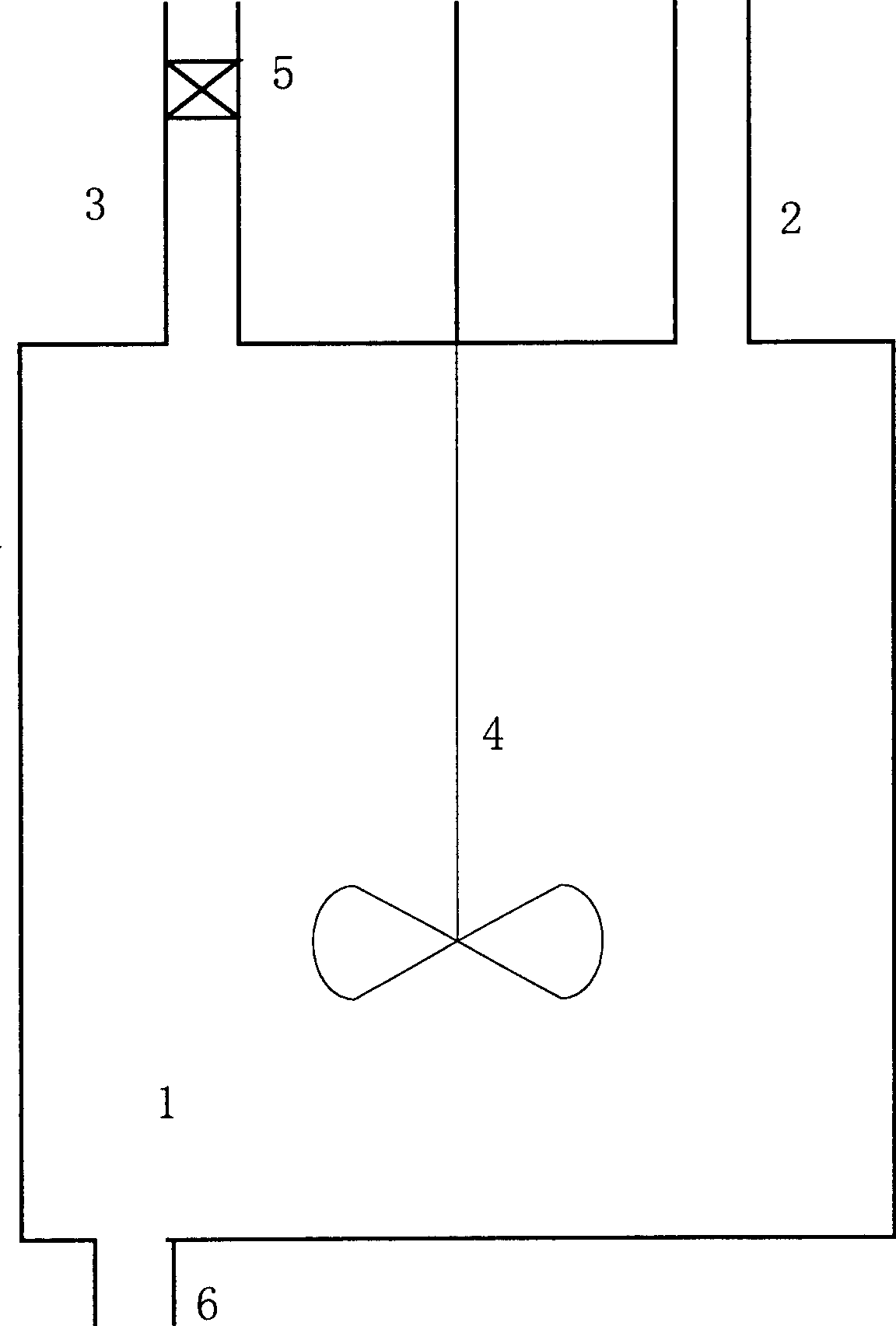

[0032] The second specific embodiment of the present invention is as figure 2 shown. The reaction device includes all components of the first embodiment, and also includes an air inlet 6 . The air inlet 6 can be located at any position of the reactor 1 , preferably, the feed inlet 2 and the gas outlet 3 are located at the upper part of the reactor 1 , and the air inlet 6 is located at the lower part of the reactor 1 . Air inlet 6 is used to add silicon tetrachloride liquid. With the gas inlet 6, the silicon tetrachloride liquid is fed from the gas inlet 6, and the feed inlet 2 is specially used for feeding the rare earth-containing Y-type zeolite solid particles, and the operation is more convenient.

[0033] When preparing the zeolite provided by the present invention, the rare earth-containing Y-type zeolite solid particles are loaded from the feed port 2, the agitator 4 is started, and the feed port 2 and the gas outlet 3 are sealed. Add silicon tetrachloride liquid fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com