Mixed sample preparation method for high-cobalt and low-cobalt powder alloy and high-cobalt and low-copper granular alloy

A low-cobalt copper, mixed technology, applied in the fields of metallurgy and analytical chemistry, can solve the problems of different proportions of copper and cobalt, and achieve the effect of strong representation, good uniformity and good representation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, content, and advantages of the present invention clearer, the specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0014] The invention provides a method for rapid mixing and sample preparation of high-copper and low-cobalt powdery red alloys with large differences in particle and composition and high-cobalt and low-copper granular white alloys. Crusher, grinder, reducer, 1mm sieve; specifically include the following steps:

[0015] Step 1, mixing red alloys and white alloys with different particle sizes and different copper and cobalt contents, basically maintaining the order of one red alloy and one white alloy during operation, and premixing;

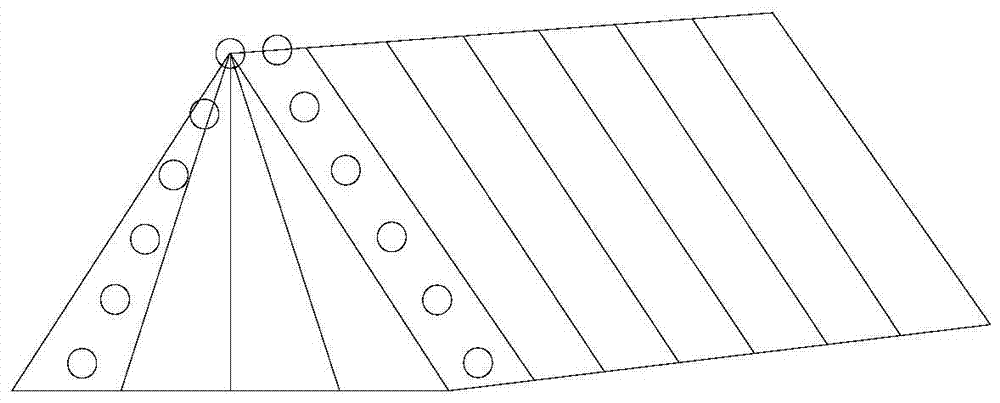

[0016] In step 2, the pre-mixed red and white alloys are shoveled and mixed for 3-5 times by the scraper, and the final alloy pile is in the shape of a triangular prism;

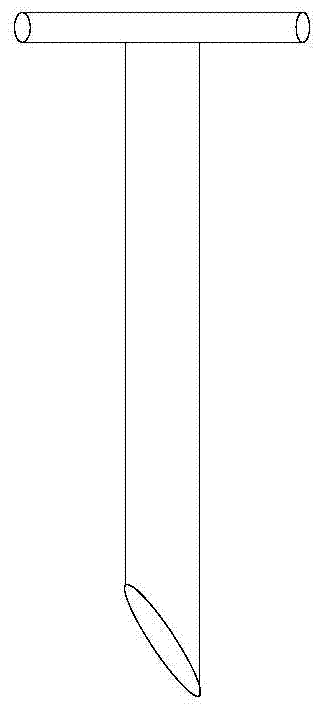

[0017] Step 3: Scribe the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com