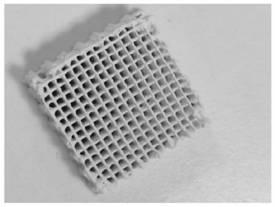

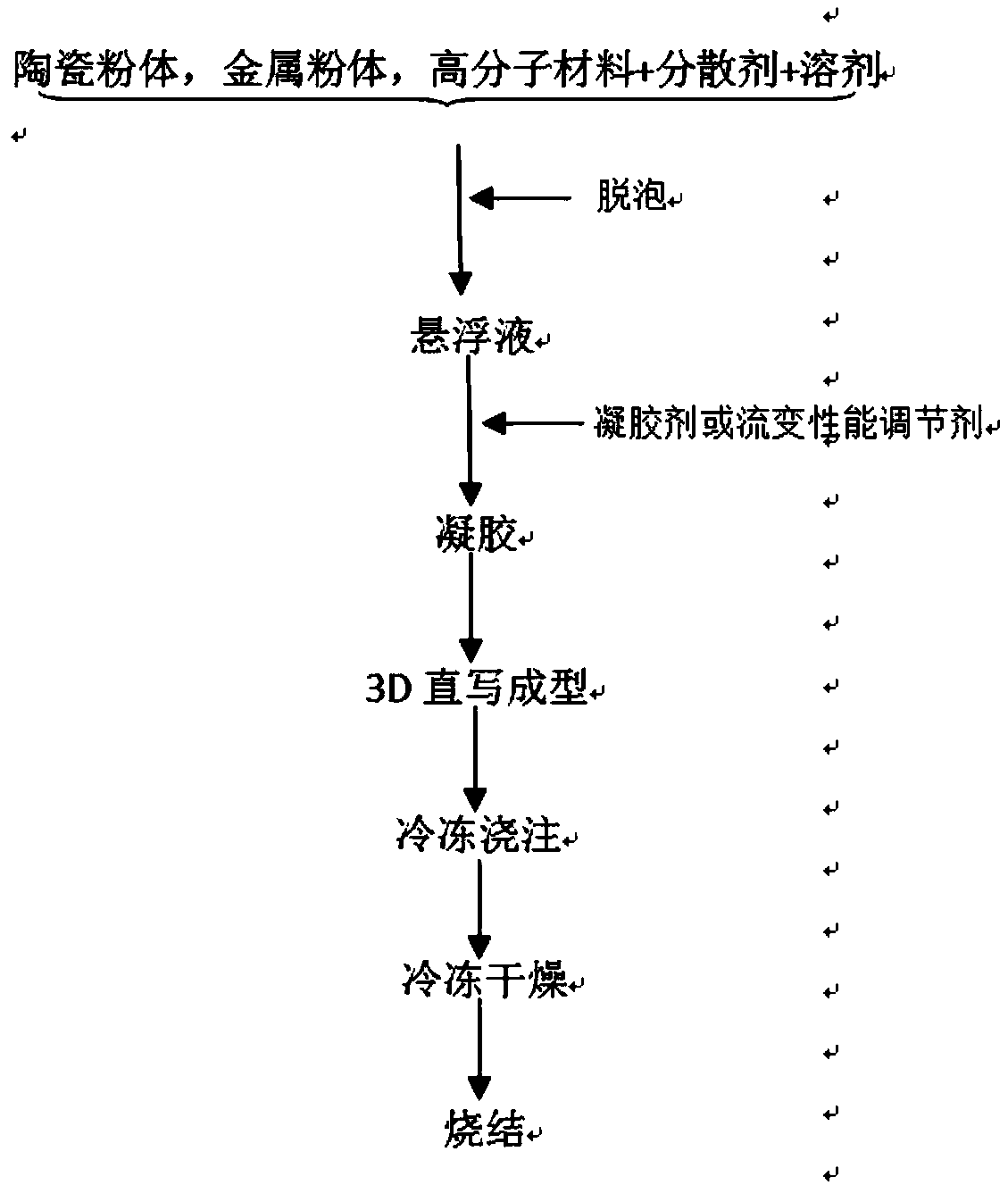

Method for preparing material with controllable macro and micro structures

A microstructure and macroscopic technology, applied in the direction of additive processing, ceramic products, applications, etc., can solve the problems of complex follow-up processing, low molding strength, and low molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] In the slurry (3D ink), the solid phase volume fraction of the zirconia particles is 10vol%; the solvent is water; the dispersant is polyethyleneimine; the addition is 0.2% of the dry powder mass of the zirconia particles, and the The zirconia particles, water, and dispersant are mixed evenly, adding zirconia grinding balls and 1-2 drops of n-octanol defoamer, after ball milling, and ultrasonically vibrating to prepare the zirconia ceramic suspension. Subsequently, gelling agent gelatin was added to the zirconia suspension, and its addition amount was 15wt.% of the solvent mass, followed by ball milling at a temperature of 60°C for 2h, and then poured into a 3D direct writing device syringe at 0°C Stand still for 8 minutes to promote the transformation of the suspension into a gel, then put the syringe loaded with hydroxyapatite gel into a 500um needle nozzle, and perform direct writing molding on the thermally conductive substrate, and control the temperature of the the...

Embodiment 2

[0096] In the slurry (3D ink), the solid phase volume fraction of zirconia particles is 35vol%; the solvent is water; the dispersant is polyacrylic acid, and the addition amount is 1.0% of the dry powder mass of zirconia particles. Mix the above raw materials to form a slurry, add zirconia grinding balls and 1-2 drops of n-octanol defoamer, and after ball milling, ultrasonically vibrate to prepare the zirconia ceramic suspension. Subsequently, gelling agent gelatin was added to the zirconia suspension in an amount of 3wt.% of the liquid phase content, followed by ball milling at a temperature of 60°C for 2h, and then poured into the syringe of a 3D direct writing device at 0°C Stand still for 1 min to promote the transformation of the suspension into a gel, then put the syringe loaded with hydroxyapatite gel into a 50um needle nozzle, and perform direct writing molding of the slurry on the thermally conductive substrate, and control the temperature of the thermally conductive s...

Embodiment 3

[0098] In the slurry (3D ink), the solid phase volume fraction of the alumina particles is 20vol%; the solvent is tert-butanol; the dispersant is PEO, and the amount of the dispersant is 0.5% of the dry powder mass of the alumina particles. %, mix the dispersant, tert-butanol, and alumina particles to form a slurry, add zirconia balls and defoamers, perform ball milling, and ultrasonically vibrate to prepare the alumina ceramic suspension. Subsequently, a gelling agent pectin was added to the alumina suspension in an amount of 7wt.% of the liquid phase content, followed by ball milling at a temperature of 60°C for 3 hours to obtain a slurry, which was poured into the slurry after gelling In the syringe of the 3D direct writing equipment, the syringe loaded with alumina gel is then loaded into a 300um needle nozzle, and the paste on the thermally conductive substrate is directly written, and the temperature of the thermally conductive substrate is controlled at 0°C. Obtain a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com