Self-cleaning type titanium dioxide nano-fiber membrane material as well as preparation method and application thereof

A nanofiber membrane, titanium dioxide technology, applied in the field of separation and treatment of environmental pollutants, can solve the problems of limiting the practical application of nanofiber membranes, low mechanical strength of nanofiber membranes, weak bonding force between nanofibers, etc. Industrial application, stable properties, high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for preparing a self-cleaning titanium dioxide nanofiber membrane material, comprising the following steps:

[0056] S0. Cut the carbon paper into small pieces of 50mm×20mm×0.20mm, then use acetone, isopropanol, ethanol and water to wash ultrasonically for 10min, and then dry at 80°C; in this step, use acetone to wash the carbon paper, and then Washing with isopropanol and ethanol in sequence can further remove impurities remaining on the surface of the carbon paper and obtain cleaner carbon paper;

[0057] S1. Add 20mL tetrabutyl titanate into a 200mL beaker, add 100mL absolute ethanol while stirring, then add 0.2mL glacial acetic acid, and keep stirring at room temperature until the reaction solution is milky white to obtain a titanium dioxide sol;

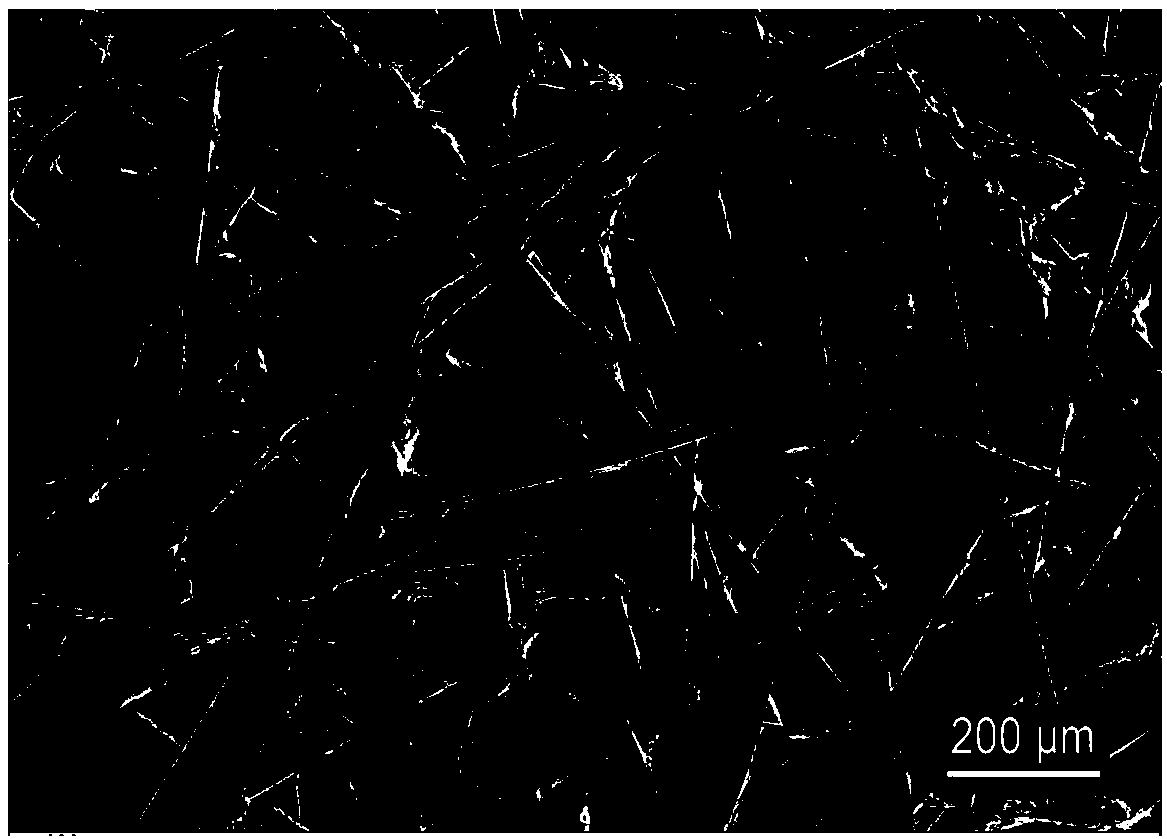

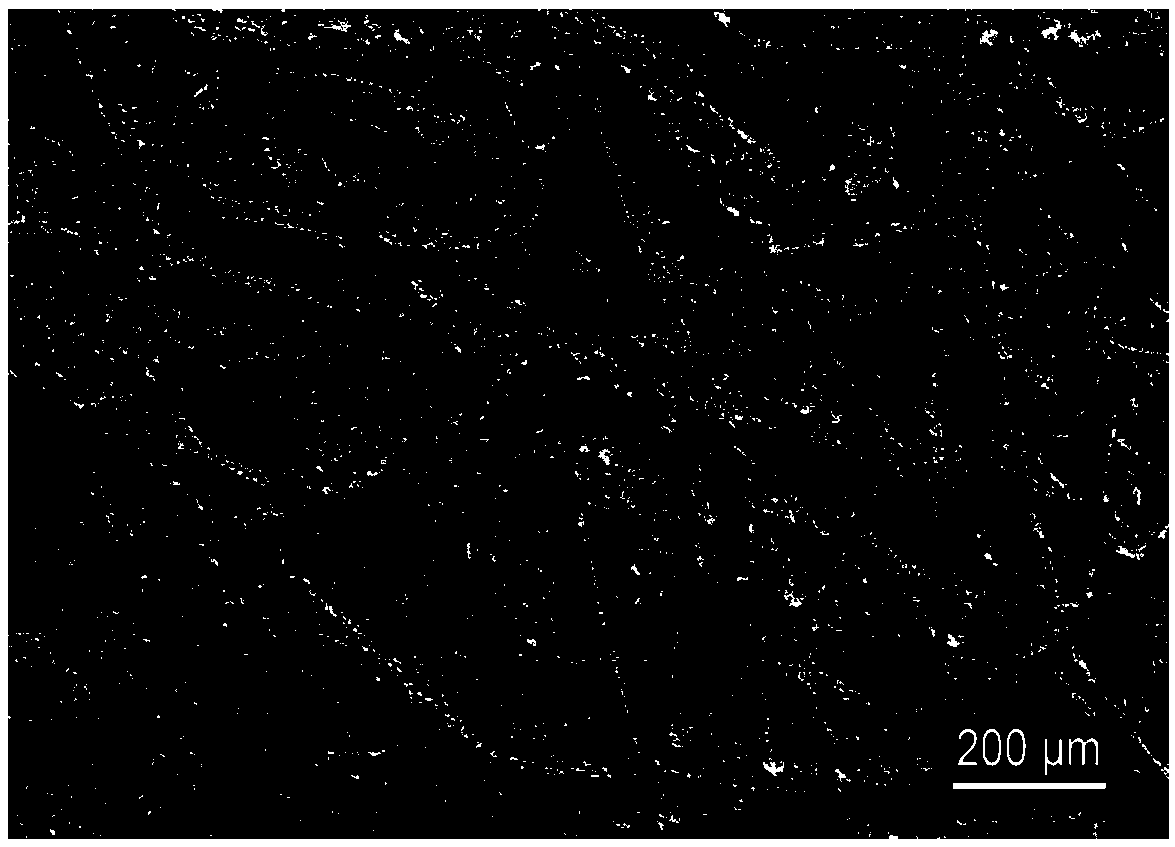

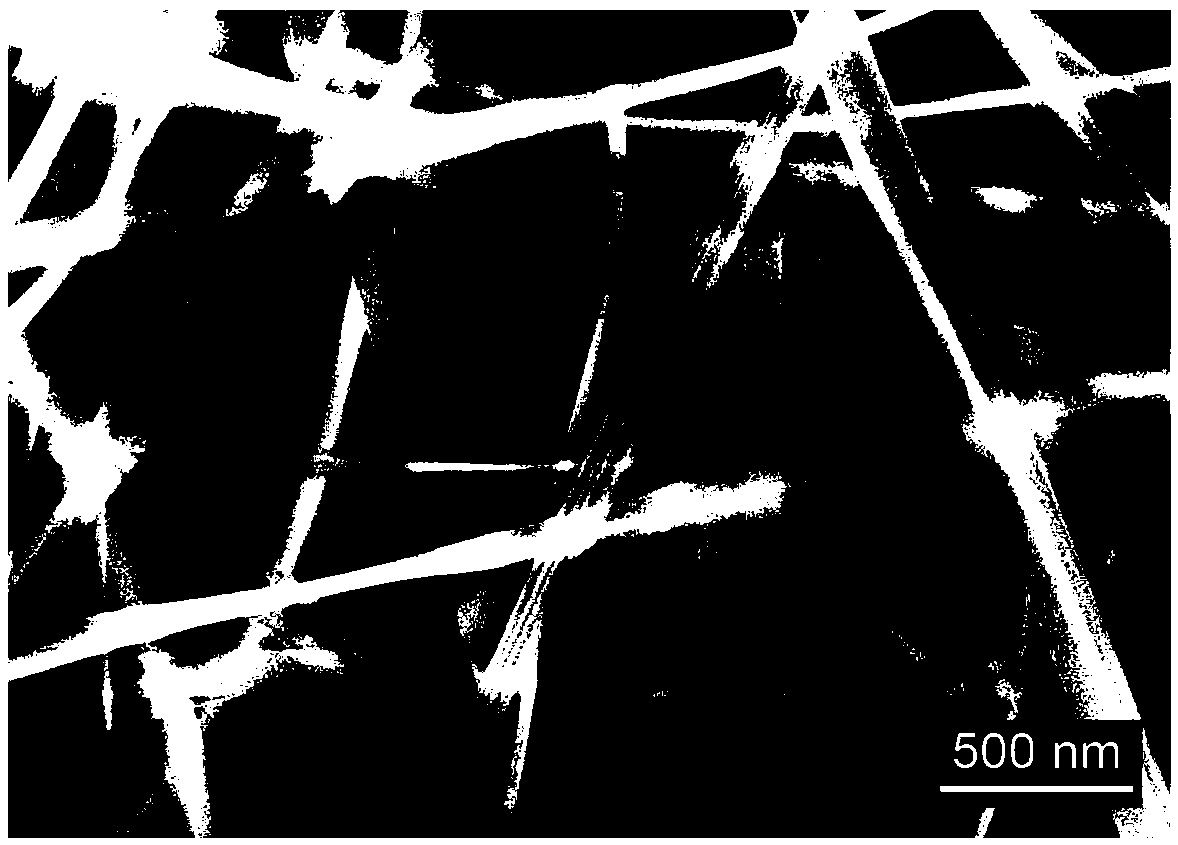

[0058] S2. impregnating the carbon paper in the titanium dioxide sol, and adsorbing titanium dioxide nanoparticles on the surface of the carbon paper to obtain carbon paper loaded with ti...

Embodiment 2

[0076] The titanium dioxide nanofiber membrane material prepared in Example 1 was used to test the filtration performance and self-cleaning performance of organic dye molecules.

[0077] First, the filtration performance of titanium dioxide nanofiber membranes for organic dye molecules was tested. Positively charged rhodamine B (hereinafter referred to as: RhB) was selected as a model molecule to study the enrichment and filtration properties of titanium dioxide nanofibrous membrane materials for organic molecules. Cut the titanium dioxide nanofiber membrane material into small pieces of 2cm×2cm, and fix them in a self-made filter device with silicone rubber. Take 7mL concentration to be 10mg·L -1 The RhB solution was placed in a self-made filter device, and the solution was allowed to pass through the titanium dioxide nanofiber membrane material automatically to reach the bottom of the device. After the solution is completely filtered, test the ultraviolet-visible absorptio...

Embodiment 3

[0087] The titanium dioxide nanofiber membrane material prepared in Example 1 was used to test the filtration performance of nanoparticles. Taking gold nanoparticles and carbon dots, which have been widely studied and applied, as the filtration objects, the filtration performance of this titanium dioxide nanofiber membrane material on fine nanometer solid particles is studied.

[0088] Figure 14 is the TEM figure of gold nanoparticles in the present invention; Figure 15 It is a TEM picture of carbon dots in the present invention. As shown, the particle sizes of the two are about 12nm and 4.5nm, respectively.

[0089] Install the plexiglass plate fixed with the titanium dioxide nanofiber membrane material in the self-made filter device, respectively add the gold nanoparticle and carbon dot dispersion liquid above the titanium dioxide nanofiber membrane material, let it stand, let the solution automatically pass through the fiber membrane to reach the bottom of the device b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com