Photoluminescent fiber and preparation method thereof

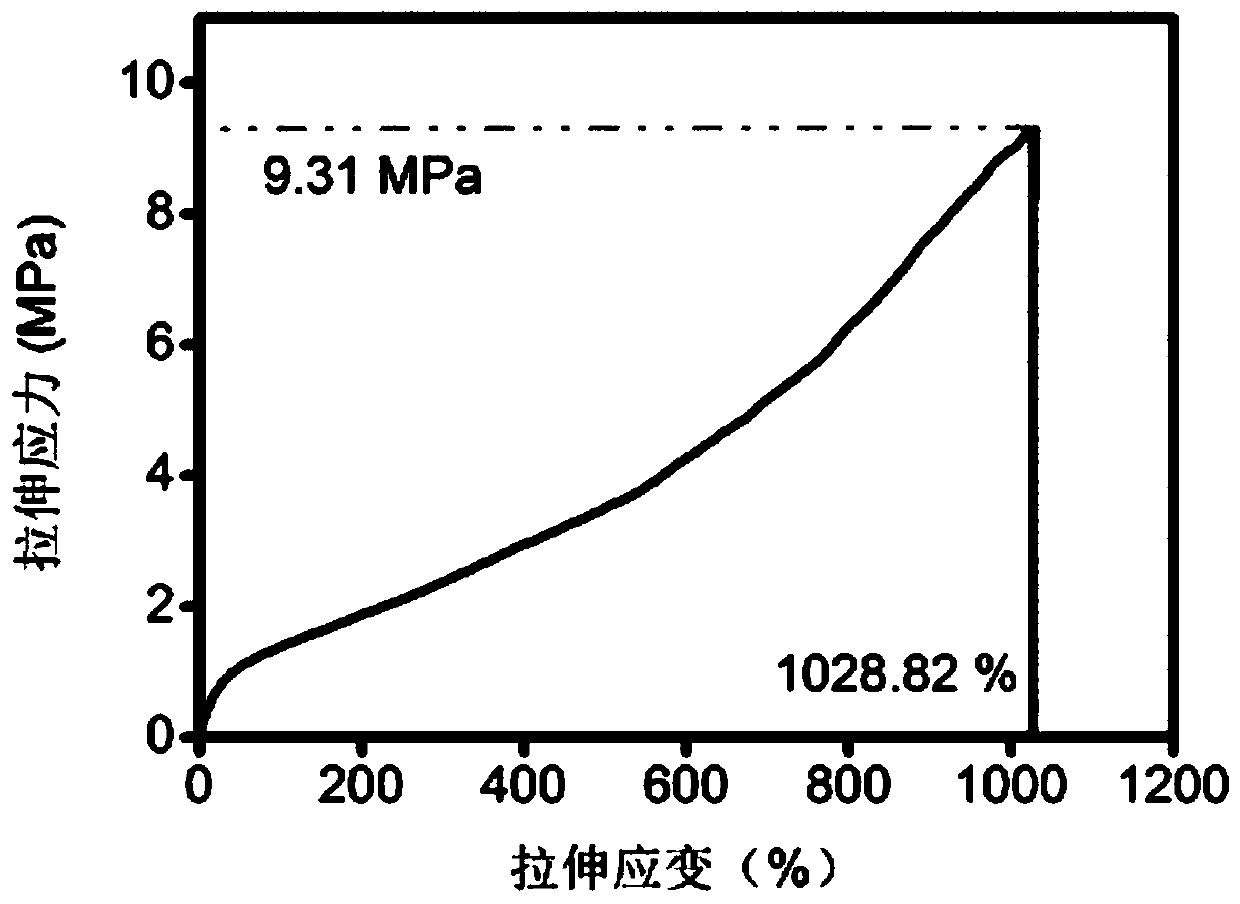

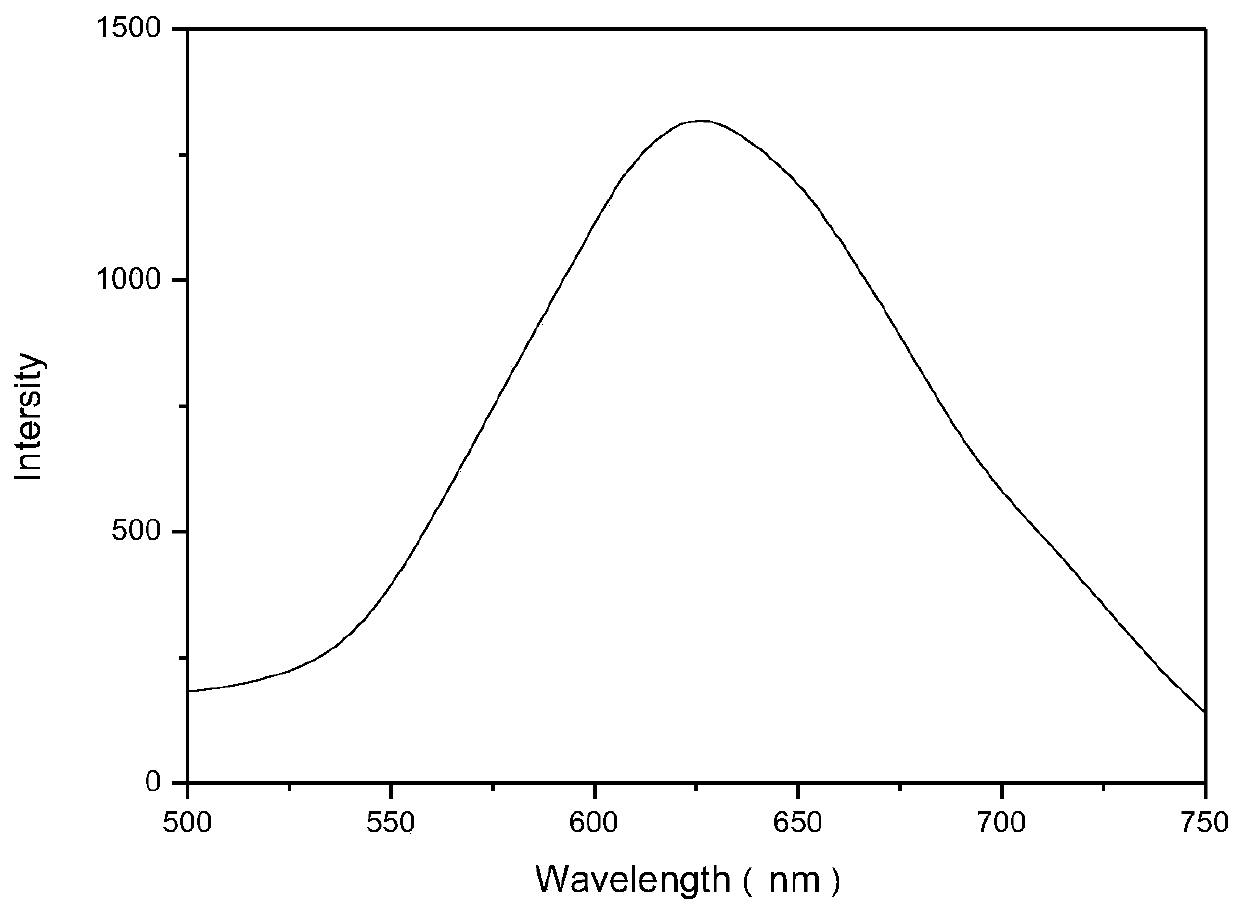

A photoluminescence, fiber technology, applied in spinning solution preparation, fiber chemical characteristics, wet spinning, etc., can solve the problems of limited application, complex process, narrow spinning solution range, etc., and achieve excellent mechanical properties, fluorescence stability. Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a photoluminescent fiber, comprising the steps of:

[0048] S1, preparing quantum dots;

[0049] S2. Preparation of spinning solution: blending a predetermined mass fraction of quantum dots and high molecular polymers in a solvent, and stirring to obtain a quantum dot / polymer spinning solution;

[0050] S3. Preparation of photoluminescent fiber: adopt wet spinning process, inject the spinning solution into the syringe, set the predetermined liquid feeding rate, spray the spinning solution into the water bath through the spinning needle, pass through the coagulation bath, and then use the predetermined volume Winding at a winding speed and drying to obtain photoluminescent fibers.

[0051]Wherein, in step S2, the mass fraction of quantum dots in the spinning solution is 0.1-10 wt%; the mass fraction of polymer in the spinning solution is 15-50 wt%.

[0052] In step S3, the volume of the syringe is 5-80 mL, the inner diameter of the spinning needl...

Embodiment 1-28

[0056] Below in conjunction with embodiment 1-28, the preparation method of photoluminescence fiber is described:

Embodiment 1

[0058] S1. Preparation of oil-dispersed silicon quantum dots:

[0059] S11. Take 0.6g of silicon powder and pour it into a container, add 20mL of absolute ethanol and 40mL of a 48% hydrofluoric acid solution and stir at room temperature with a rotation speed of 600r / min for 4.5h;

[0060] S12. Extract with an appropriate amount of n-pentane, quickly separate the dark brown solution in the upper layer into the reactor, add 20 mL of decene into the reactor, and then vacuum dry it;

[0061] S13. Put the reactor into an oven, the reaction condition is to raise the room temperature to 170° C. in 1 hour, keep at this temperature for 6 hours, and then lower the temperature to room temperature in 6 hours;

[0062] S14. After the reaction is completed, transfer the reaction kettle solution to a centrifuge tube, add petroleum ether (boiling range of 60-90°C) to 35mL for the first centrifugation, the speed is 7000r / min, and the time is 15min; take the upper layer 15mL clear liquid Add m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com