Preparation and usage methods of high-temperature CO2 modified calcium-based adsorbent

A calcium-based adsorbent and CO2 technology, which is applied in the field of preparation of high-temperature CO2-modified calcium-based adsorbents, can solve the problems of easy sintering of adsorbents and clogging of adsorbent micropores, so as to achieve large-scale industrial application and avoid sintering , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

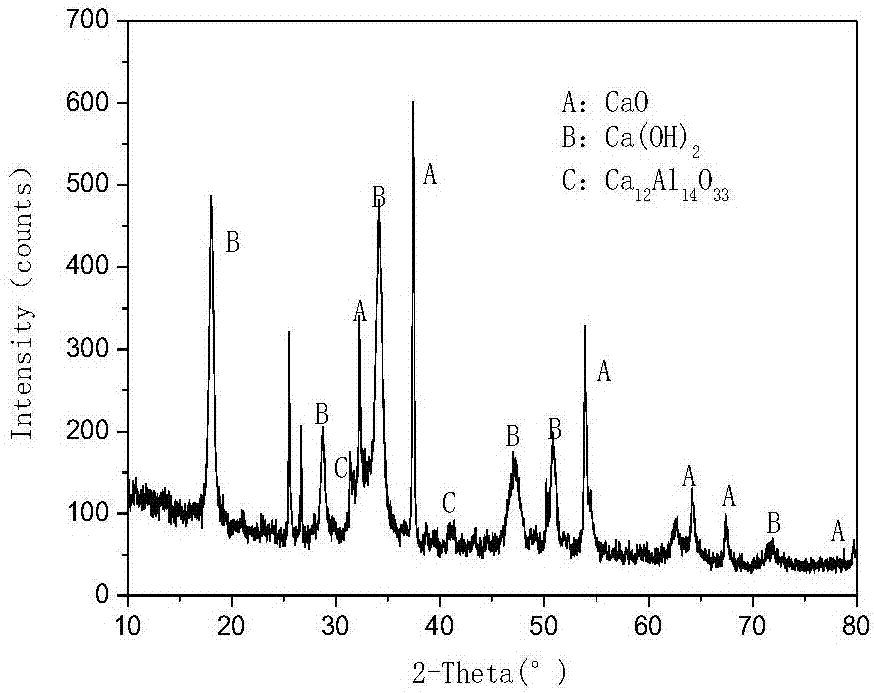

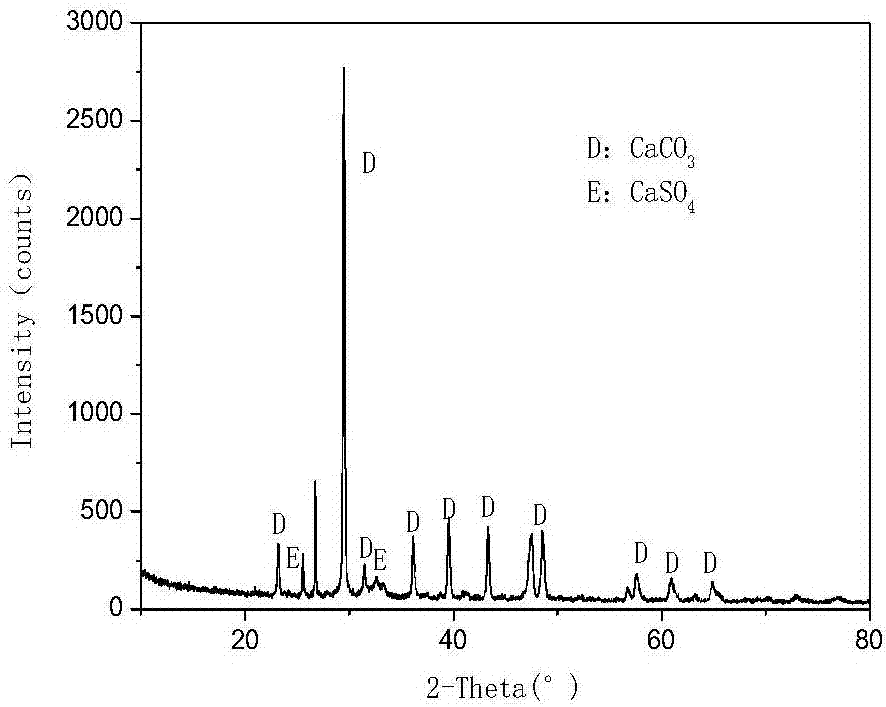

[0035] The preparation method: using oil sand pyrolysis residue as calcium source, compounding kaolinite, high-temperature calcination, heating hydration modification and molding with ethanol solution to obtain a large specific surface area and pore structure, and can be more Secondary high temperature CO 2 Calcium based sorbent.

[0036] Specific steps are as follows:

[0037] (1) Preparation of oil sand pyrolysis residue to remove high temperature CO 2 The preparation method of the modified calcium-based adsorbent comprises the following steps:

[0038] ① Blending and preparation of adsorbent raw materials: oil sand pyrolysis residue and kaolinite are added to the grinder at a mass ratio of 6:1 to 8:1 for grinding and blending to obtain a mixture powder with a particle size of less than 0.5mm ;

[0039] ② Calcination of adsorbent raw materials: spread the mixed powder obtained in ①, and fully calcined by temperature programming to obtain calcium-based adsorbent materials...

Embodiment 1

[0055] Example 1: Preparation of high temperature CO from oil sand pyrolysis residue 2 The method for modifying the calcium-based adsorbent, the specific operations are as follows:

[0056] (1) According to the mass ratio of 7:1, the oil sand pyrolysis residue and kaolinite are mixed and added to the grinder for grinding and blending to obtain a mixture powder with a particle size of less than 0.5 mm.

[0057] (2) Raise the temperature to 450°C at a heating rate of 15°C / min, and keep at this temperature for 30 minutes, continue to heat up to 800°C, and fully calcined at this temperature for 1 hour to obtain calcium-based raw materials;

[0058] (3) Weigh the calcium-based raw material obtained in step (1) and mix it with 65% ethanol solution, then heat and hydrate at 40°C; the mass ratio of the calcium-based raw material to the ethanol solution is 1:1, and the hydration reaction time is 6h ;

[0059] (4) Apply the modified calcium-based adsorbent to high temperature CO 2 Cy...

Embodiment 2

[0060] Example 2: Preparation of high temperature CO from oil sand pyrolysis residue 2 The method for modifying the calcium-based adsorbent, the specific operations are as follows:

[0061] (1) According to the mass ratio of 8:1, the oil sand pyrolysis residue and kaolinite are mixed and added to the grinder for grinding and blending to obtain a mixture powder with a particle size of less than 0.5 mm.

[0062] (2) Raise the temperature to 500°C at a heating rate of 15°C / min, and keep at this temperature for 20 minutes, continue to heat up to 700°C, and fully calcined at this temperature for 1.5 hours to obtain calcium-based raw materials;

[0063] (3) Weigh the calcium-based raw material obtained in step (1) and mix it with 65% ethanol solution, then heat and hydrate at 50°C; the mass ratio of the calcium-based raw material to the ethanol solution is 1:1, and the hydration reaction time is 4h ;

[0064] (4) Apply the modified calcium-based adsorbent to high temperature CO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com