Gas phase aluminium extracting and silicon supplementing method of molecular sieve

A technology of extracting aluminum to supplement silicon and molecular sieves, which is applied in the fields of crystalline aluminosilicate zeolite, tobacco, and other applications, can solve the problems of difficult control of reaction conditions, uneven reaction temperature, poor heat transfer performance, etc., and achieve easy large-scale industrial application, ease of control, and the effect of reducing losses and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

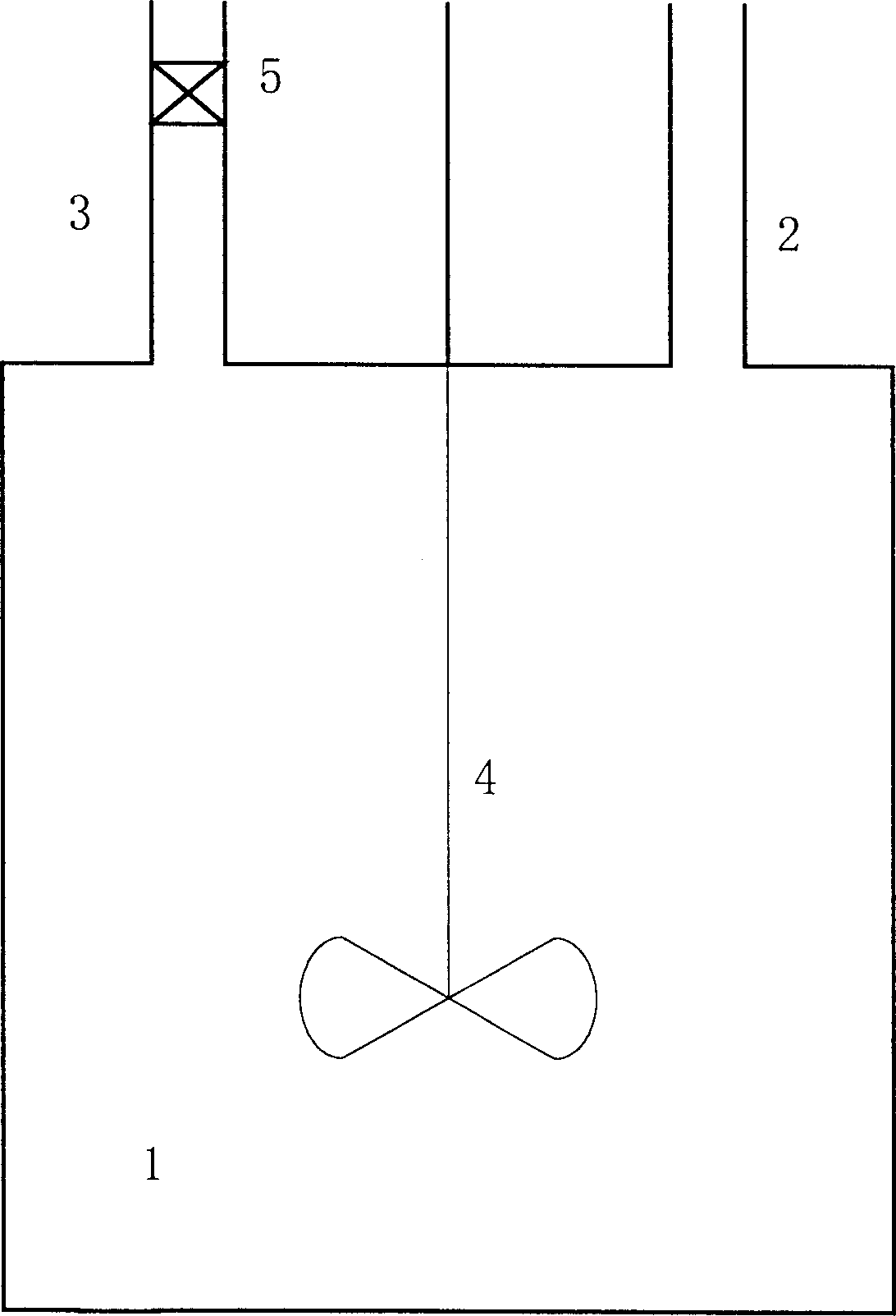

[0029] The first specific embodiment of the present invention is as follows figure 1shown. Described reaction equipment comprises a reactor 1, a feed port 2 and a gas outlet 3, also has a stirrer 4 inside the reactor 1, and wherein, a gas-solid separator 5 is installed on the gas outlet 3, gas The hole diameter and porosity of the holes contained in the solid separator 5 ensure that the gas can pass through but the solid particles cannot pass through. The stirring rod of the stirrer 4 stretches out of the reaction kettle 1, and the place where the stirring rod contacts the reaction kettle 1 is airtight, so that the reaction kettle 1 is not connected to the outside world.

[0030] When carrying out aluminum extraction and silicon supplementation, molecular sieve solid particles are loaded from the feed port 2, the agitator 4 is started, and silicon tetrachloride liquid is added, and the feed port 2 and the gas outlet 3 are sealed. Heat the reaction kettle 1 to the reaction t...

Embodiment approach 2

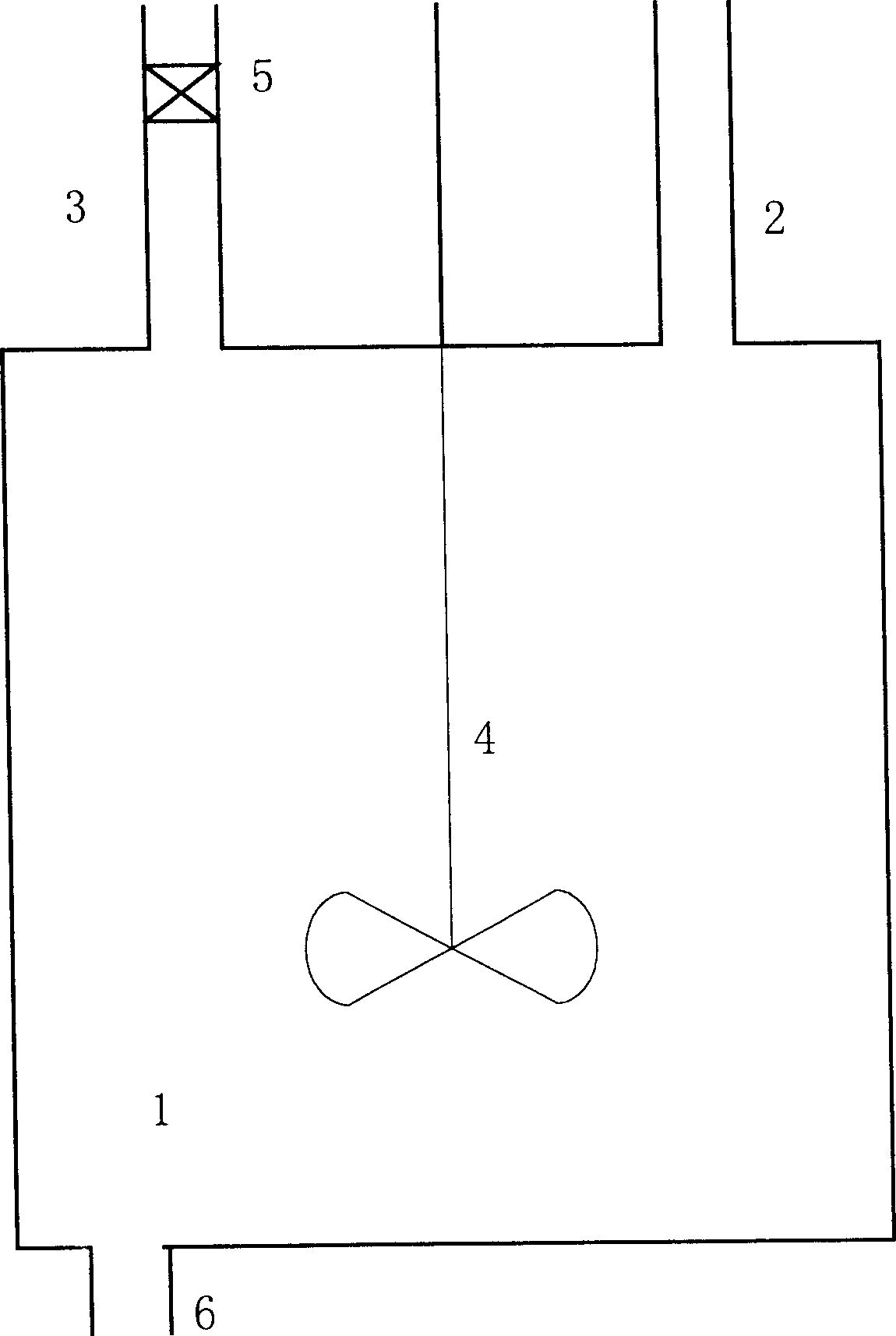

[0032] The second specific embodiment of the present invention is as figure 2 shown. The reaction device includes all components of the first embodiment, and also includes an air inlet 6 . The air inlet 6 can be located at any position of the reactor 1 , preferably, the feed inlet 2 and the gas outlet 3 are located at the upper part of the reactor 1 , and the air inlet 6 is located at the lower part of the reactor 1 . Air inlet 6 is used to add silicon tetrachloride liquid. With the air inlet 6, the silicon tetrachloride liquid is added from the air inlet 6, and the feed inlet 2 is specially used for adding molecular sieve solid particles, and the operation is more convenient.

[0033] When performing aluminum extraction and silicon supplementation, molecular sieve solid particles are loaded from the feed port 2, the agitator 4 is started, and the feed port 2 and the gas outlet 3 are sealed. Add silicon tetrachloride liquid from air inlet 6, air inlet 6 is airtight or the ...

Embodiment approach 3

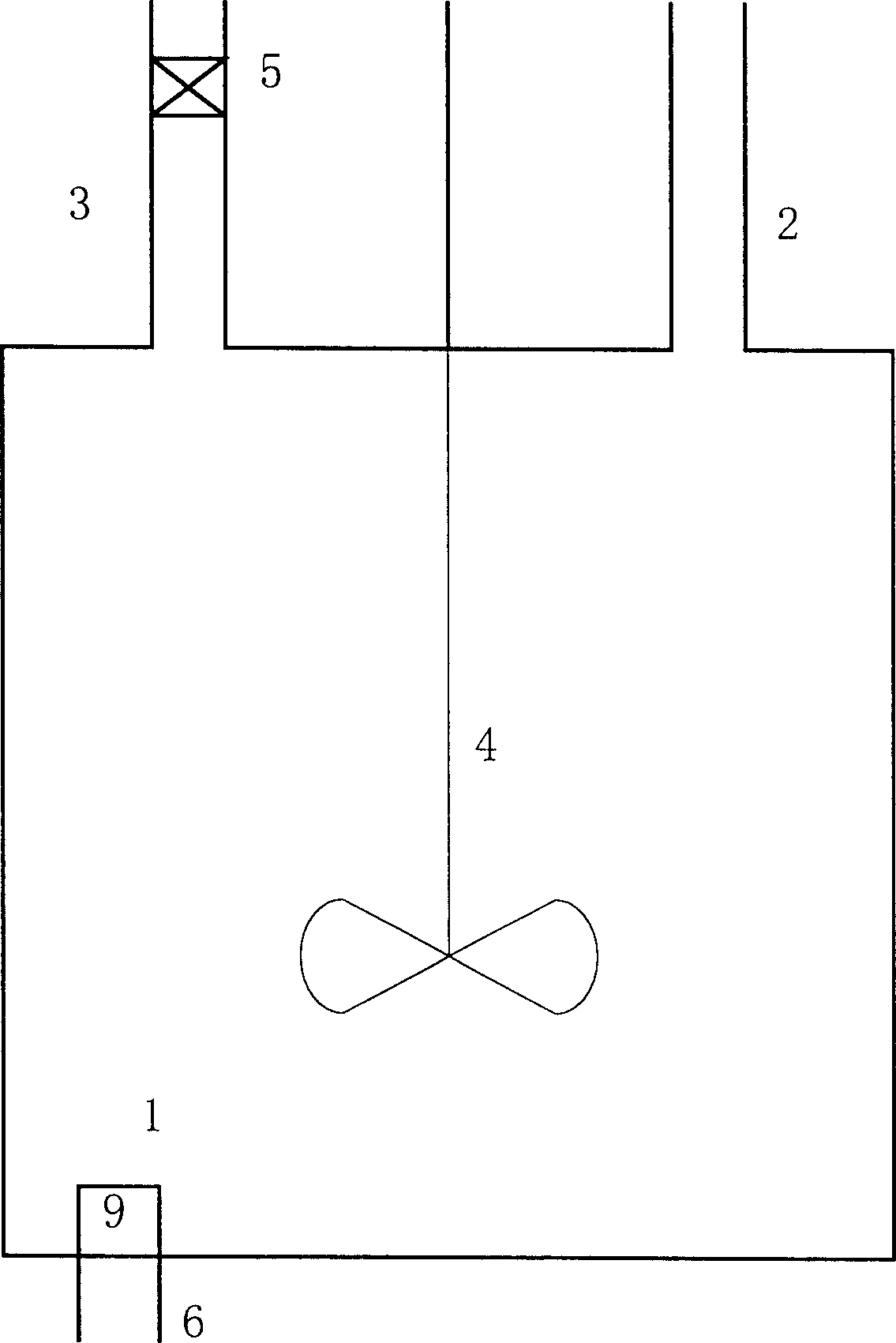

[0035] The third specific embodiment of the present invention is as image 3 shown. The reaction equipment includes all the components of the second specific embodiment, and a gas distributor 9 is installed on the top of the air inlet 6, and the top of the gas distributor 9 is on a plane or at the height of the bottom of the reactor 1. On the plane where the bottom of the reactor 1 is located. The function of the gas distributor is to enable the silicon tetrachloride gas to enter the reactor 1 continuously and evenly, and at the same time, ensure that the molecular sieve solid particles do not enter the pipeline connected to the air inlet 6 .

[0036] When carrying out aluminum extraction and silicon supplementation, molecular sieve solid particles are loaded from the feed port 2, the feed port 2 and the gas outlet 3 are sealed, the agitator 4 is started, and the feed port 2 is sealed. Add silicon tetrachloride liquid from air inlet 6, air inlet 6 is sealed or the pressure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com