Modified metal organic frame porous adsorption material, and working pair thereof

A metal-organic framework, porous adsorption material technology, used in heat exchange materials, other chemical processes, chemical instruments and methods, etc., can solve the problems of large volume, limit evaporation temperature, etc., achieve large specific surface area, wide source, adsorption The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

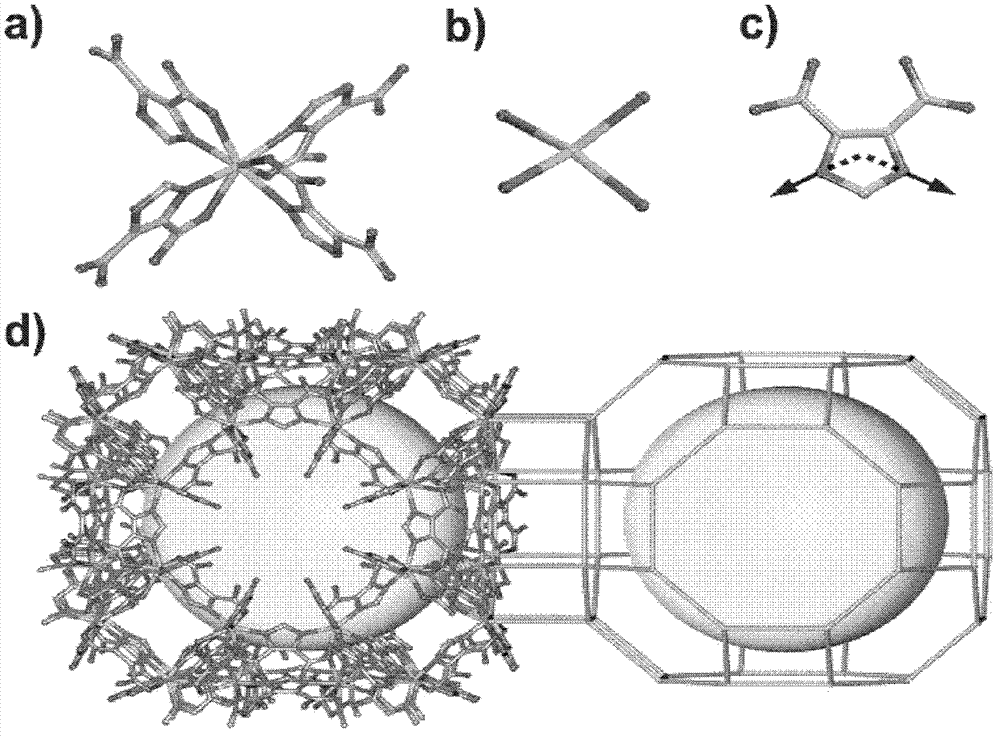

[0027] Indium nitrate dihydrate and imidazole 4,5-dicarboxylate were dissolved in N,N-dimethylformamide in a ratio of (1:2), mixed evenly and poured into a polytetrafluoroethylene reactor, the reaction temperature was 85°C , the reaction time is 24h, and the three-dimensional cage-like network skeleton structure adsorbent is formed by complexing through the hydrothermal synthesis method. It forms an adsorption working medium pair with water, and at 25°C and 0.1MPa, the refrigerating capacity per unit mass of the adsorbent can reach 1187.74KJ / kg; The capacity can reach 423.17KJ / kg; when it forms an adsorption working medium pair with ethanol, at 25°C and 0.1MPa, the refrigerating capacity per unit mass of the adsorbent can reach 323.33KJ / kg. The adsorbent cage skeleton described in the implementation case 1 is composed of dodecahedral MBB (InN 4 (CO 2 ) 4 ) form, each indium atom and four H 3 Four nitrogen atoms and four oxygen atoms are connected in the ImDC ligand. The t...

Embodiment example 2

[0029] Nickel nitrate, benzene tricarboxylate and 1,2-bis(1,2,4-triazol-4-yl)ethane were dissolved in N,N-dimethylformaldehyde in the ratio of (1:1:3) In the amide, stirring at 25°C for 60 minutes, reaction temperature at 250°C, and reaction time of 24 hours, complexation by hydrothermal synthesis to form a three-dimensional skeleton structure. It forms a working medium pair with water, and under typical air-conditioning conditions (evaporation temperature 10°C), the refrigerating capacity per unit mass of the adsorbent reaches 518.28KJ / kg. The three-dimensional network structure of the adsorbent described in Example 2 is composed of benzenetricarboxylic acid, 1,2-bis(1,2,4-triazol-4-yl, nickel atoms, oxygen atoms and the like.

Embodiment example 3

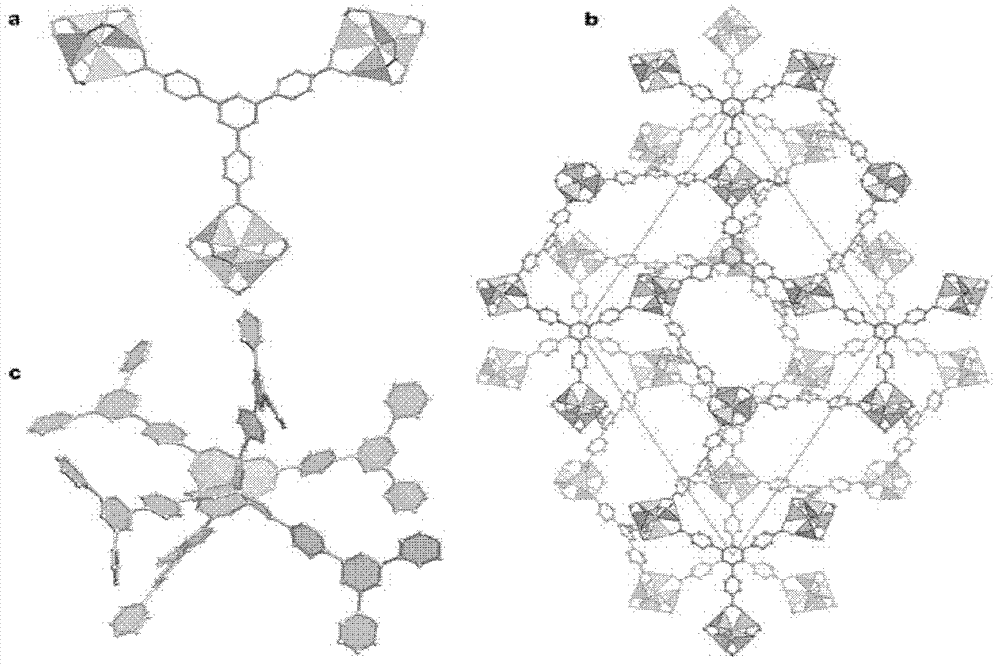

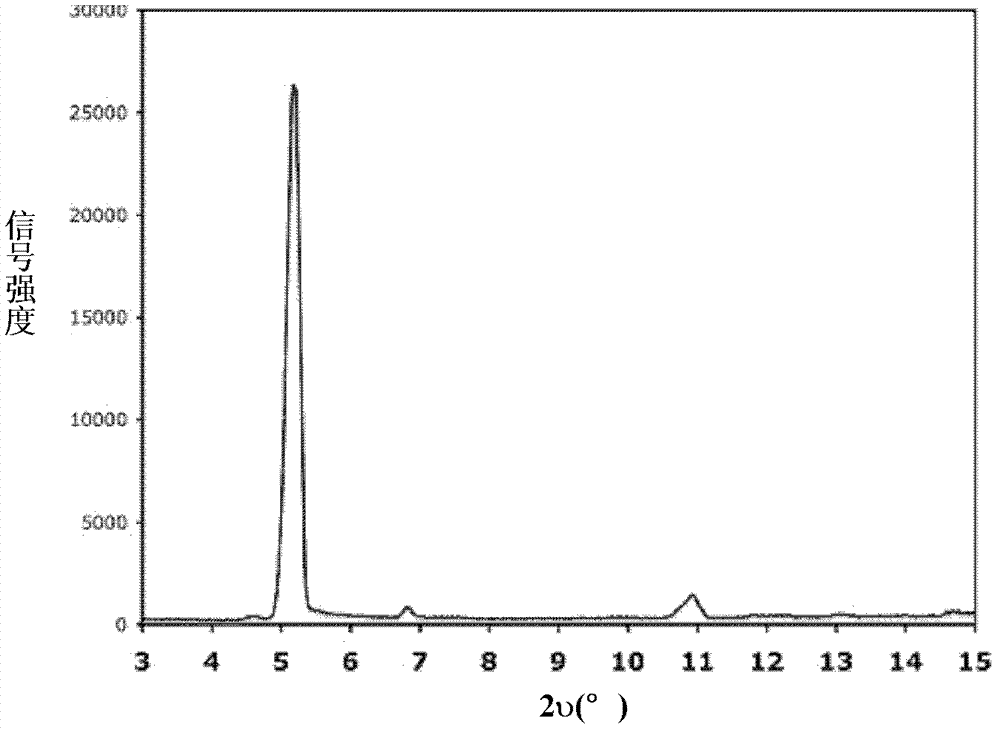

[0031] Zinc nitrate and benzene tribenzoate were dissolved in N,N-diethylformamide in a ratio of (4:5), stirred at 25°C for 10 minutes, the reaction temperature was 80°C, and the reaction time was 72 hours, and synthesized by hydrothermal complexation to form a three-dimensional framework. It forms an adsorption working pair with ammonia, and at 25°C and 0.1MPa, the refrigerating capacity per unit mass of the adsorbent can reach 283.72KJ / kg. In the implementation case 3, the network skeleton structure of the adsorbent is composed of a benzenetribenzoic acid unit and 3 Zn 4 O phase connection, Zn 4 Structural fragments on O include hexacyclic rings and zinc atoms. The adsorbent has a network structure of (6,3) coordination, the octahedron in the figure has 6 coordination points, and the center is a benzenetricarboxylic acid unit with three coordination points. The three-dimensional network framework structure and XRD pattern of the adsorbent are shown in figure 2 and ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com