Double-stage adsorption refrigerating recycling system

A technology of adsorption refrigeration and circulation system, applied in the cross field of refrigeration and air conditioning, to achieve the effect of strong water absorption, improve efficiency and reduce system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

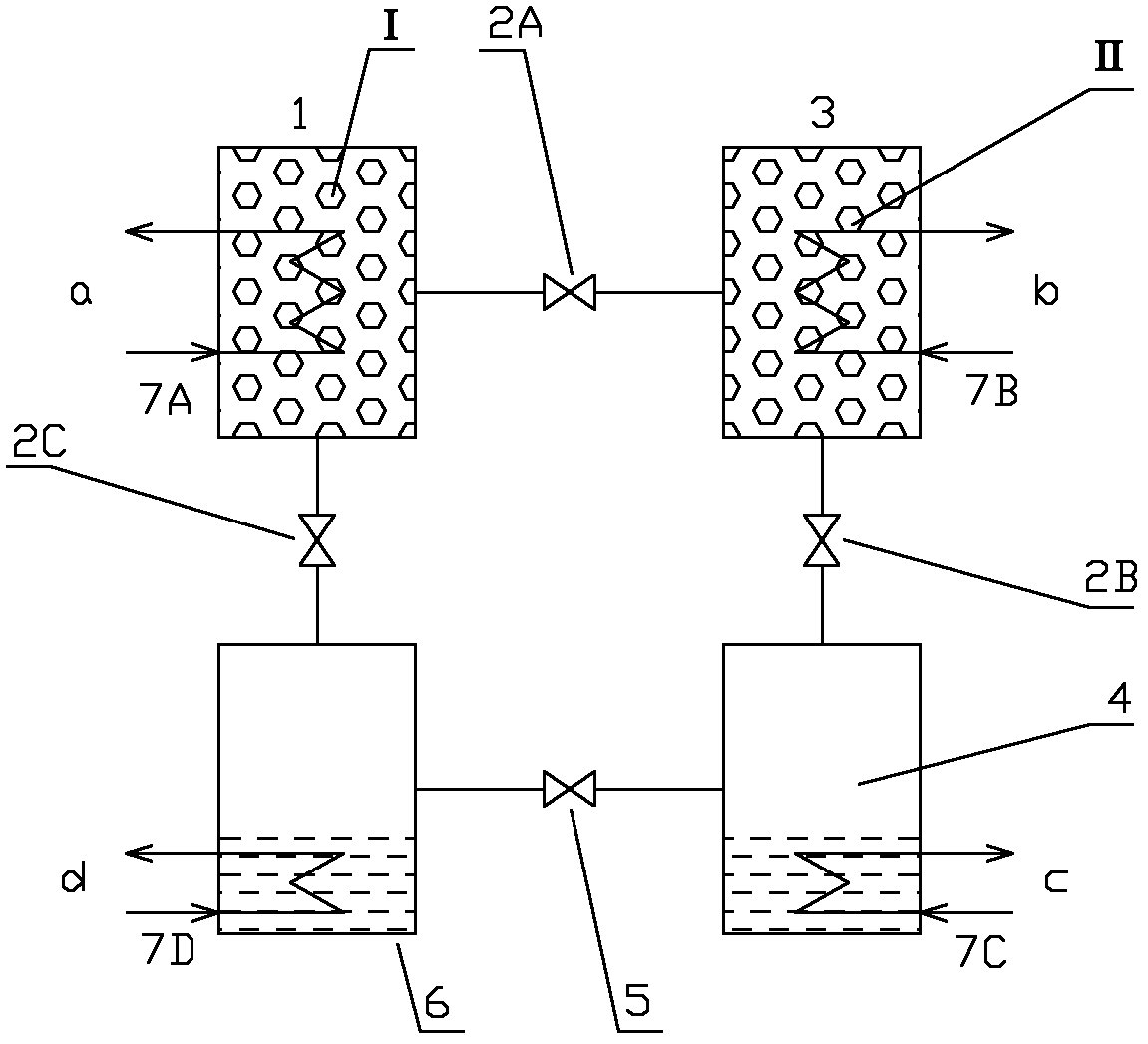

[0032] The two-stage adsorption refrigeration cycle system is composed of primary adsorption bed 1, secondary adsorption bed 3, condenser 4, evaporator 6, valves and other auxiliary components. The primary adsorption bed 1 is filled with adsorbent I, FeSAPO-34, and the primary adsorption bed 1 conducts heat exchange with the outside through the heat exchange medium a through the first heat exchange tube 7A; the primary adsorption bed 1 passes through the first valve 2A and the second The primary adsorption bed 3 is connected, and the secondary adsorption bed 3 is equipped with adsorbent II, fine-pore silica gel, and the quality of the fine-pore silica gel is 50% of FeSAPO-34; the secondary adsorption bed 3 passes through the heat exchange medium b through the second heat exchange The tube 7B performs heat exchange with the outside; the secondary adsorption bed 3 is further connected to the condenser 4 through the second valve 2B, and the condenser 4 is filled with refrigerant w...

Embodiment 2

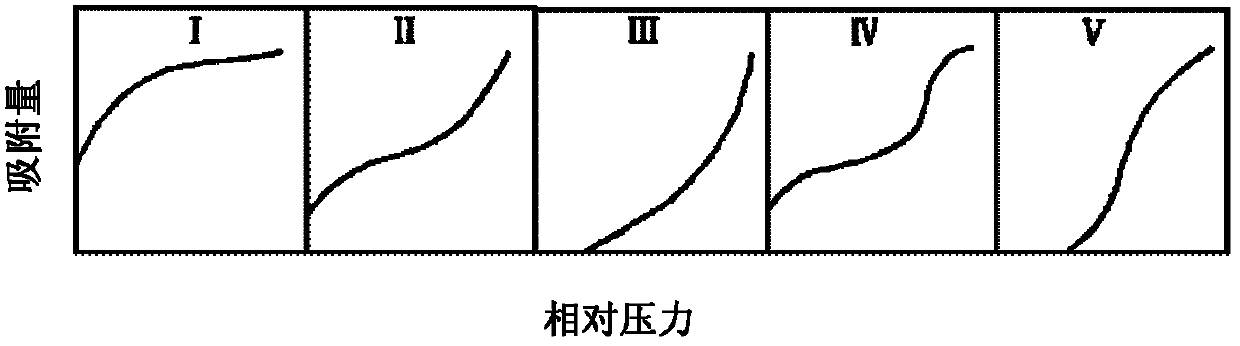

[0041] In the primary adsorption bed 1 of the present invention, GaSAPO-34 adsorbent is filled, and its structural formula is 0.1R (Si 0.02 · Ga 0.40 ·Al 0.30 ·P 0.28 )·O 2 ; R is a mixture of 30% (mol fraction) of diethylamine and 70% (mol fraction) of triethylamine; the ratio of the number of weak acid centers of adsorbent I to the total surface acid content is 80%; adsorbent I microporous The pore size is between 0.3~0.6nm; the water absorption isotherm of adsorbent I belongs to the type IV isotherm classified by Brunauer, and the adsorption heat is 45~50kJ / mol.

[0042] Adsorbent I is prepared by hydrothermal method. The preparation process is as follows: 1) Weigh template agent, silicon source, aluminum source, phosphorus source, heteroatom source and water raw material according to the ratio of adsorbent I structural formula, mix and stir to form a gel ; 2) Crystallization reaction at 150°C for 50h, and adsorbent I was obtained by filtration, washing, drying and roas...

Embodiment 3

[0045] In the primary adsorption bed 1 of the present invention, FeSAPO-34 adsorbent is filled, and its structural formula is 0.4R (Si 0.35 · Fe 0.40 ·Al 0.10 ·P 0.15 )·O 2 ; The templating agent is a mixture of 60% (mol fraction) diethylamine and 40% (mol fraction) triethylamine; the ratio of the weak acid sites of the adsorbent I to the total surface acid content is 95%; the adsorbent I microporous The pore size is between 0.5-0.7nm; the water absorption isotherm of adsorbent I belongs to the type IV isotherm classified by Brunauer, and the adsorption heat is 47-52kJ / mol.

[0046] Adsorbent I is prepared by hydrothermal method. The preparation process is as follows: 1) Weigh template agent, silicon source, aluminum source, phosphorus source, heteroatom source and water raw material according to the ratio of adsorbent I structural formula, mix and stir to form a gel ; 2) Crystallization reaction at 250°C for 2 hours, and adsorbent I was obtained by filtering, washing, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com