Preparation method and application of double-functional composite Co modified particle

A dual-function, granular technology, applied in the energy field, can solve problems such as complex production steps, and achieve the effect of high equipment requirements, low equipment requirements, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

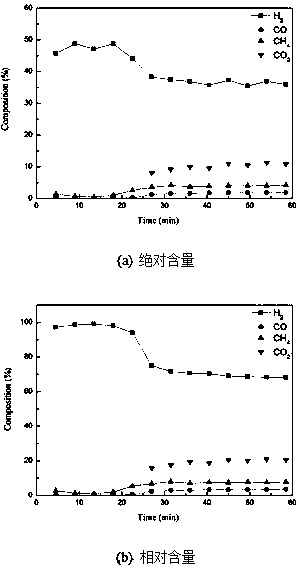

[0023] Weigh 9.42g of calcium acetate, 1.83g of cobalt nitrate hexahydrate, 0.45g of nickel nitrate and 5.62g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 100°C, and then calcined at 900°C for 3h Co-modified composite bifunctional particles of 24-50 meshes were obtained by crushing. In the adsorption-enhanced ethanol steam reforming hydrogen production reaction, 1.24 g of this bifunctional particle was used as a catalyst, and the space velocity of ethanol was 20 h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 600°C, such as figure 1 .

[0024] Such as figure 1 As shown in (b), before 20 minutes, the hydrogen concentration reached 97%. After 15 minutes, the adsorption of the adsorbent gradually reached saturation, and the relative content of hydrogen gradually decreased, and finally stabilized at about 73%. It can b...

Embodiment 2

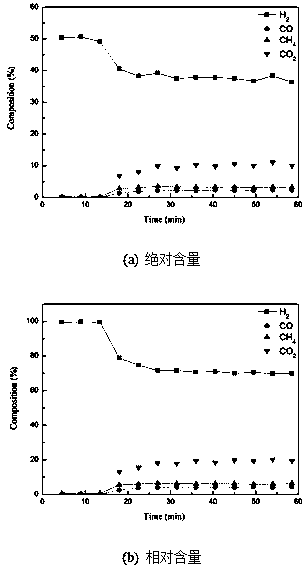

[0026] Weigh 9.42g of calcium acetate, 1.83g of cobalt nitrate hexahydrate, 0.45g of nickel nitrate and 5.62g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 100°C, and then calcined at 900°C for 3h Co-modified composite bifunctional particles of 24-50 meshes were obtained by crushing. In the adsorption-enhanced glycerol steam reforming hydrogen production reaction, 1.24 g of this bifunctional particle was used as a catalyst, and the space velocity of glycerol was 20 h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 600°C, such as figure 2 .

[0027] Such as figure 2 As shown in (b), before 13 minutes, the hydrogen concentration reached 97%. After 15 minutes, the adsorption of the adsorbent gradually reached saturation, and the relative content of hydrogen gradually decreased, and finally stabilized at about 70%. It c...

Embodiment 3

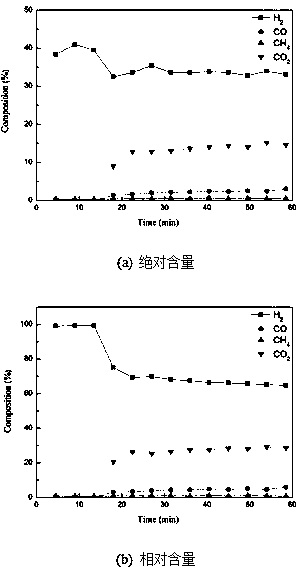

[0029] Weigh 9.42g of calcium acetate, 1.83g of cobalt nitrate hexahydrate, 0.45g of nickel nitrate and 5.62g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 100°C, and then calcined at 900°C for 3h Co-modified composite bifunctional particles of 24-50 meshes were obtained by crushing. In the adsorption-enhanced acetic acid steam reforming hydrogen production reaction, 1.24 g of this bifunctional particle was used as a catalyst, and the space velocity of acetic acid was 22 h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 600°C, such as image 3 .

[0030] Such as image 3 As shown in (b), before 13 minutes, the hydrogen concentration reached 98%. After 15 minutes, the adsorption of the adsorbent gradually reached saturation, and the relative content of hydrogen gradually decreased, and finally stabilized at about 68%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com