Water treatment filter element

A filter element and water treatment technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problem of easy breakage of joints, and achieve the effect of prolonging adsorption time, effective filtration and good filtration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

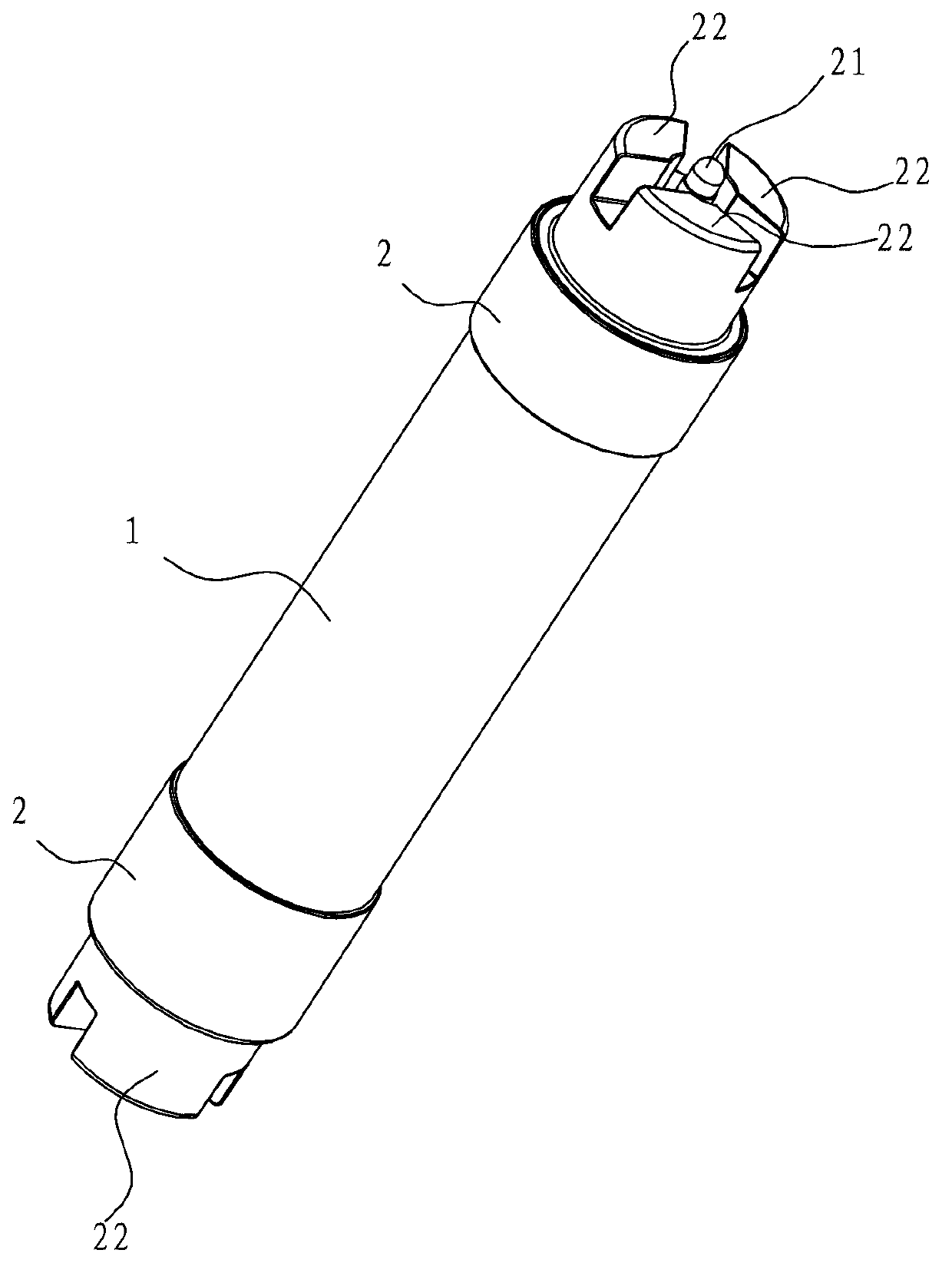

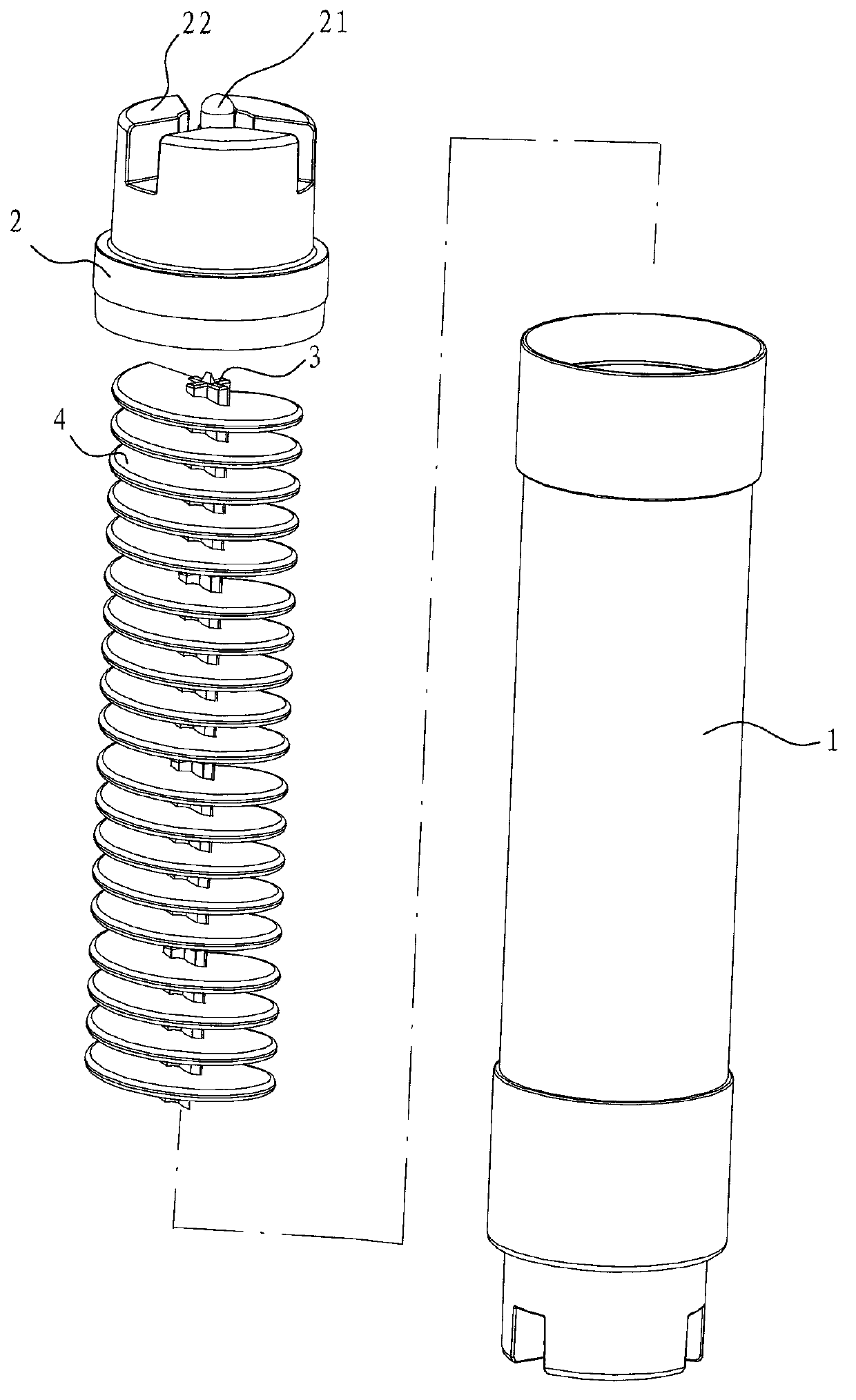

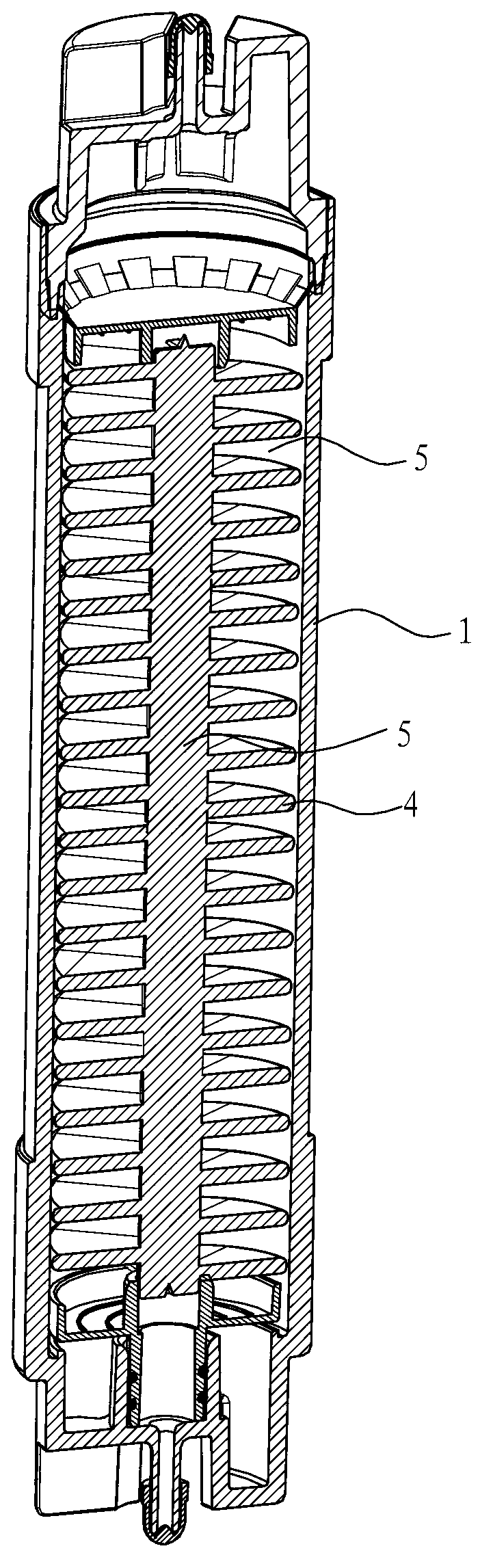

[0016] Such as figure 1 The shown filter core includes a hollow tubular shell 1, the end of the hollow tubular shell 1 is an end cover 2, and the end cover is provided with a joint 21 connected to the external structure, and the end cover 2 is also provided with a A protective post 22 that is flush with the length of the joint 21. There are three protective pillars 22 , the cross section of which is in the shape of an annular sector, and the three protective pillars 22 surround the joint 21 at the center. The hollow tubular shell 1 has a separator 3 arranged axially along the interior of the hollow tubular shell, and the separator 3 is provided with a separator 4 that is spirally distributed around the outer circumference of the separator. A spiral filter channel 5 is formed between the distributed separators 4 , the separator 3 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com