Method for repairing sludge heavy metal by combination of DTPA and ryegrass

A heavy metal and ryegrass technology, applied in biological sludge treatment, botany equipment and methods, horticulture, etc., can solve the problems of high heavy metals and secondary pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

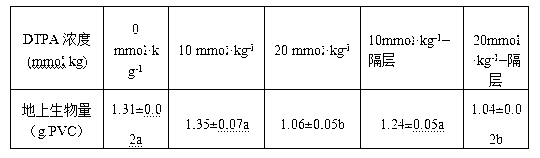

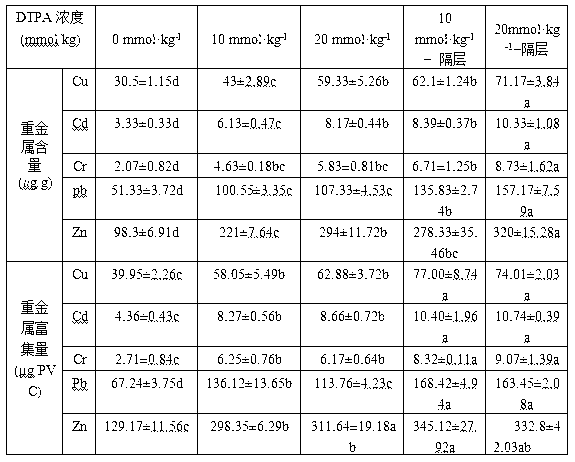

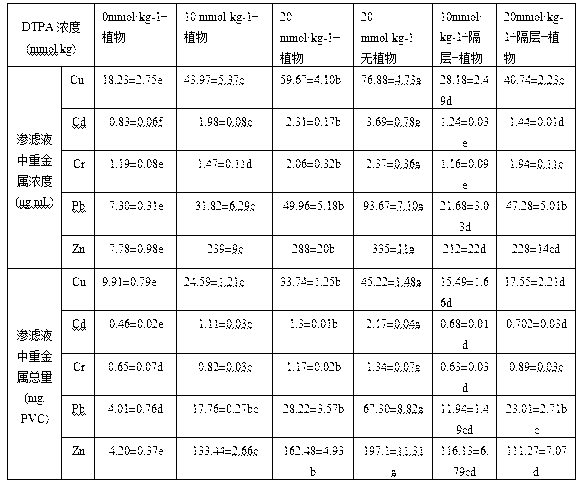

Examples

Embodiment 1

[0054] The corncob interlayer is characterized in that it is composed of 40g vermiculite+40g zeolite+40g corncob.

[0055] The method for repairing heavy metals in sludge by DTPA combined with ryegrass is characterized in that it proceeds in the following steps:

[0056] (1) In the PVC pipe, the lower end is sealed with cotton cloth and nylon mesh, filled with 1000g of air-dried garden soil, paved, and then filled with 750g of mixed matrix; the mixed matrix refers to: sludge: weight of garden soil The ratio of parts is 1:2, and the sludge is spread on the garden soil;

[0057] (2) Add an interlayer between the PVC pipe garden soil and the mixed matrix; the interlayer is composed of 40 g vermiculite + 40 g zeolite + 40 g corn cob;

[0058] (3) Sow 1.0 g of ryegrass seeds in PVC pipes, irrigate with tap water, supply water normally during the cultivation period, and keep the overall field water holding capacity at 60%; Intensity of 450 μmol?m -2 ?s -1 ;

[0059] (4) 30 days...

Embodiment 2

[0062] The corncob interlayer is characterized in that it is composed of 40g vermiculite+60g zeolite+100g corncob.

[0063] The method for repairing heavy metals in sludge by DTPA combined with ryegrass is characterized in that it proceeds in the following steps:

[0064] (1) In the PVC pipe, the lower end is sealed with cotton cloth and nylon mesh, filled with 1000g of air-dried garden soil, paved, and then filled with 750g of mixed matrix; the mixed matrix refers to: sludge: weight of garden soil The ratio of parts is 1:2, and the sludge is spread on the garden soil;

[0065] (2) Add an interlayer between the PVC pipe garden soil and the mixed matrix; the interlayer is composed of 40g vermiculite+60g zeolite+100g corn cob;

[0066] (3) Sow 1.0 g of ryegrass seeds in PVC pipes, irrigate with tap water, supply water normally during the cultivation period, and keep the overall field water holding capacity at 60%; during the planting period, the indoor temperature and relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com