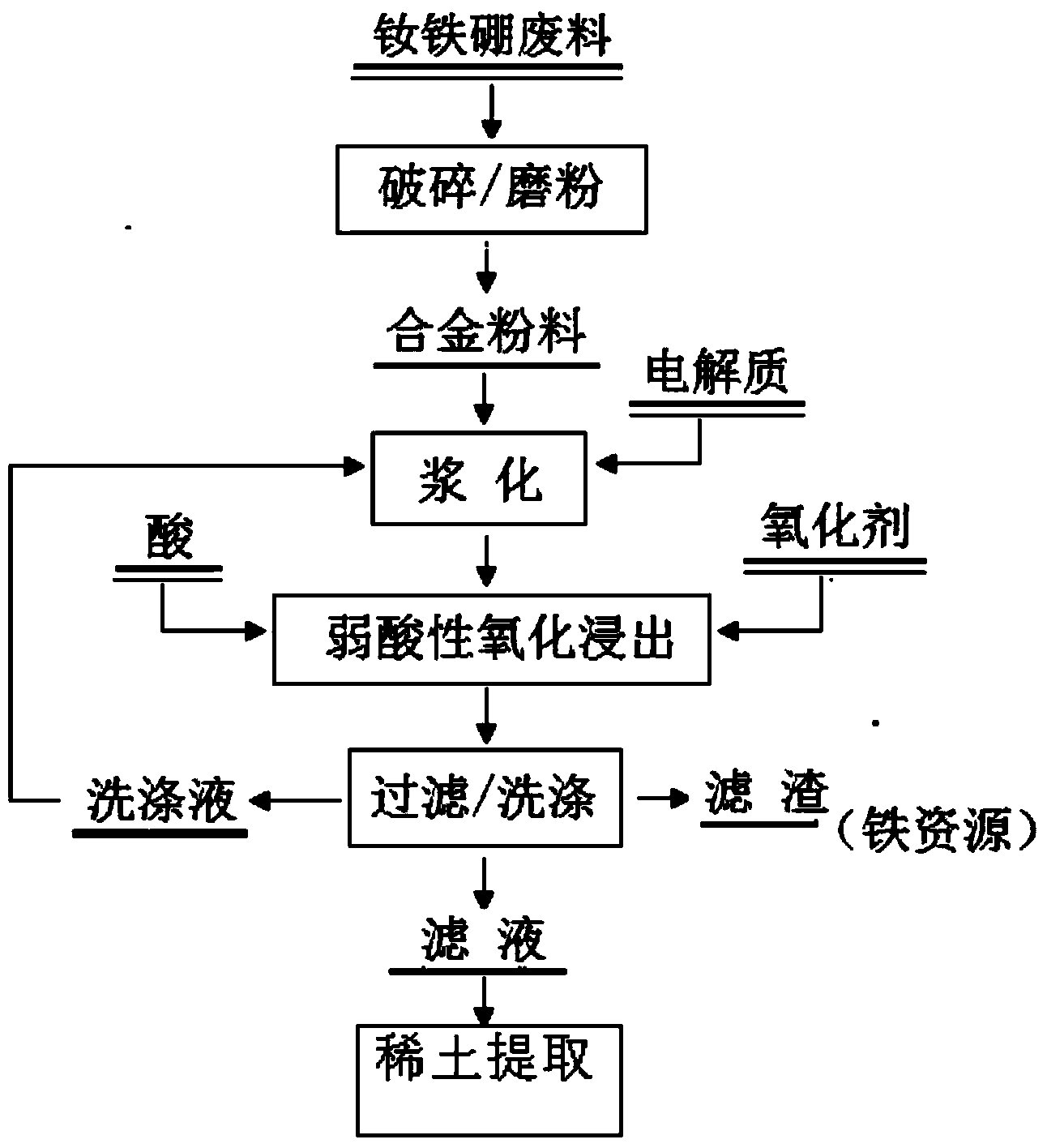

Method for dissolving out rare-earth by treating waste neodymium-iron-boron materials

A neodymium iron boron and rare earth technology, applied in the direction of improving process efficiency, can solve the problems of fast oxidative roasting, large acid consumption, high energy consumption, improve rare earth extraction rate, high rare earth leaching rate, and easy environmental treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use 2.2mol / L sodium chloride solution to slurry the powdery material at a liquid-to-solid mass ratio of 4:1, then heat and stir to dissolve the rare earth. According to the total leaching time, it is divided into three stages of leaching operation; each stage of leaching time is 20 minutes; the temperature of the first, second and third stage is controlled at 85-90°C, 80-85°C and 70-80°C respectively; each stage of leaching is drummed into the industrial Oxygen and hydrochloric acid are added from the first and second sections respectively, and the solution potential in the leaching tank is controlled at +400~+600mV, pH2.5~3.5; pH3.5~4.5. After the dissolution process is completed and the solid-liquid separation is completed, the main metal element content (g / L) in the filtrate is: rare earth 65.7; Fe4.6.

[0036] After treatment, the leaching rates (%) of rare earth and iron in waste NdFeB materials are: 88.7; 3.1.

Embodiment 2

[0038] Use 0.8mol / L sodium chloride solution to slurry the powdery material at a liquid-to-solid mass ratio of 8:1, then heat and stir to dissolve the rare earth. According to the total leaching time, it is divided into four stages of leaching operations; each stage of leaching time is 10 minutes; the temperature of the first, second, third, and fourth stages is controlled at 75-80°C, 70-75°C, 70-75°C and 50-70°C; Industrial oxygen is blown into each stage of leaching; hydrochloric acid is added from the first, second and third stages respectively to control the solution potential +500~+700mV and pH2.5~3.5 in the leaching tank; the fourth stage is the post-leaching stage, The leaching end point is the solution potential +700~+800mV, pH3.5~4.5. After the dissolution process is completed and the solid-liquid separation is completed, the main metal element content (g / L) in the filtrate is: rare earth 35.0; Fe2.7.

[0039] After treatment, the leaching rates (%) of rare earth and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com