Waste heat regeneration absorption dryer

An adsorption dryer and waste heat technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of poor cooling effect, affect drying effect, poor adsorption effect, etc., and achieve good cooling effect. The effect of less impact force and enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

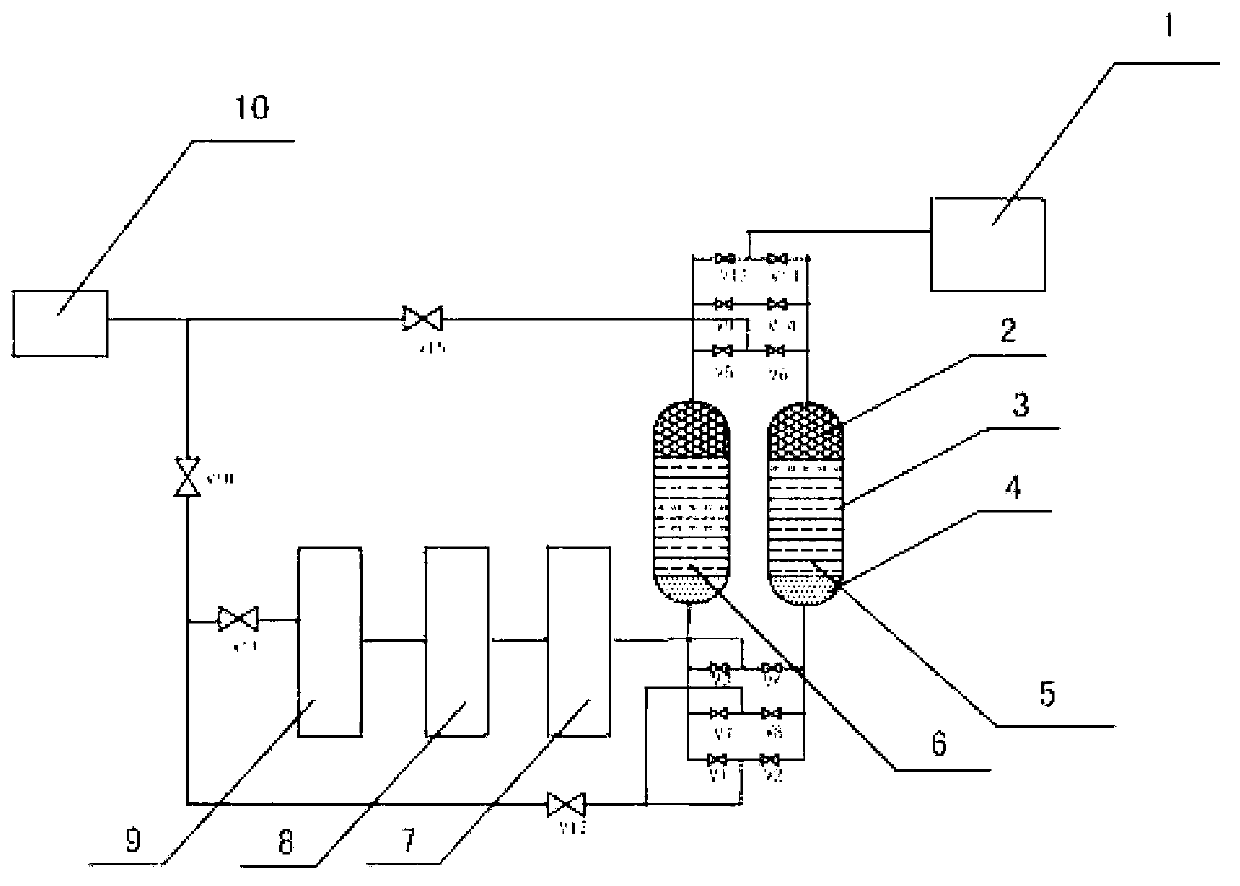

[0016] Such as figure 1 As shown, it includes an air compressor 10, the air compressor 10 is sequentially connected to the stop valve V15, the pneumatic valve V5 and the adsorption tower A tower 6, the stop valve V15 is connected to the adsorption tower B tower 5 through the pneumatic valve V6, the adsorption tower A tower 6 and the adsorption tower Tower B and tower 5 are respectively equipped with three layers of adsorption layers. From bottom to top, the first layer is the large-grain water-absorbable sphere layer 4, the second layer is the molecular sieve layer 3, and the third layer is the activated alumina layer 2. The adsorption tower A tower 6 passes through the Return valve V7 is connected with check valve V11, adsorption tower B is connected with check valve V11 through check valve V8, adsorption tower A is connected with check valve V16 through pneumatic valve V1, and adsorption tower B is connected with pneumatic valve V2 Check valve V16, check valve V16 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com