Vacuum pressure swing adsorption system

A vacuum pressure swing adsorption and vacuum technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the amount of compressed air, prolonging the vacuum desorption time, shortening the adsorption time, etc., and reducing the pumping speed of the vacuum pump , prolong the vacuum desorption time, shorten the effect of adsorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

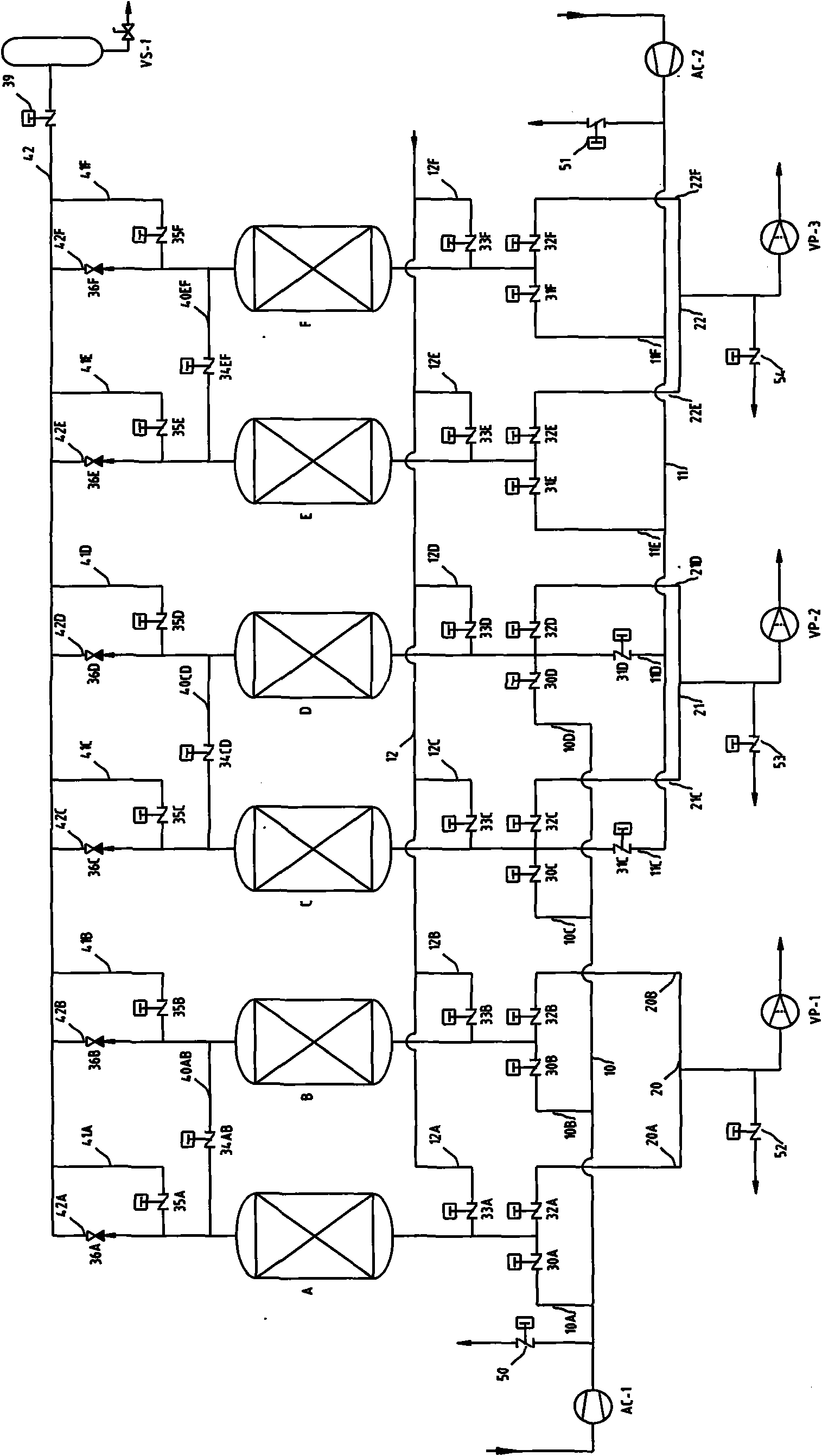

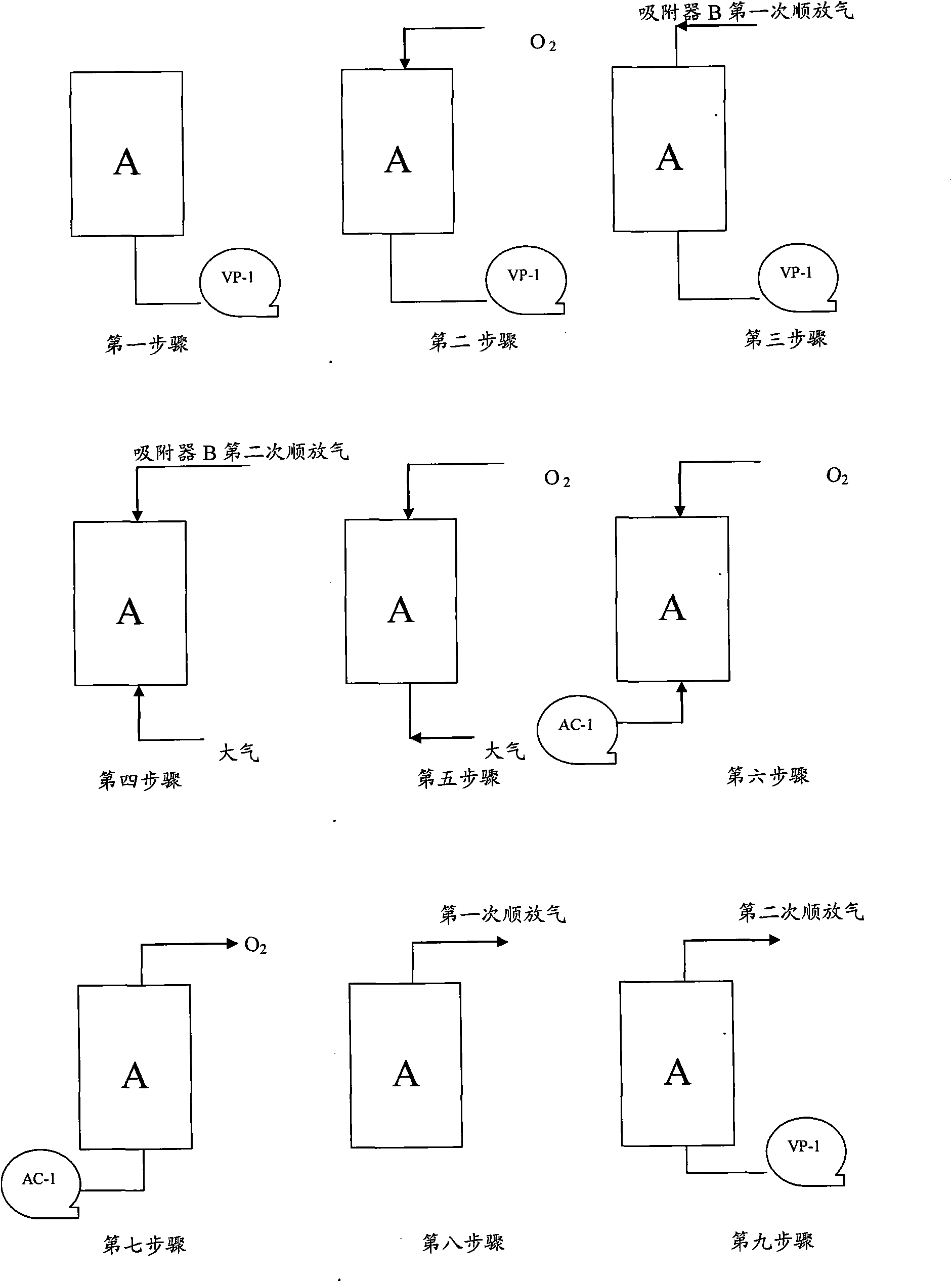

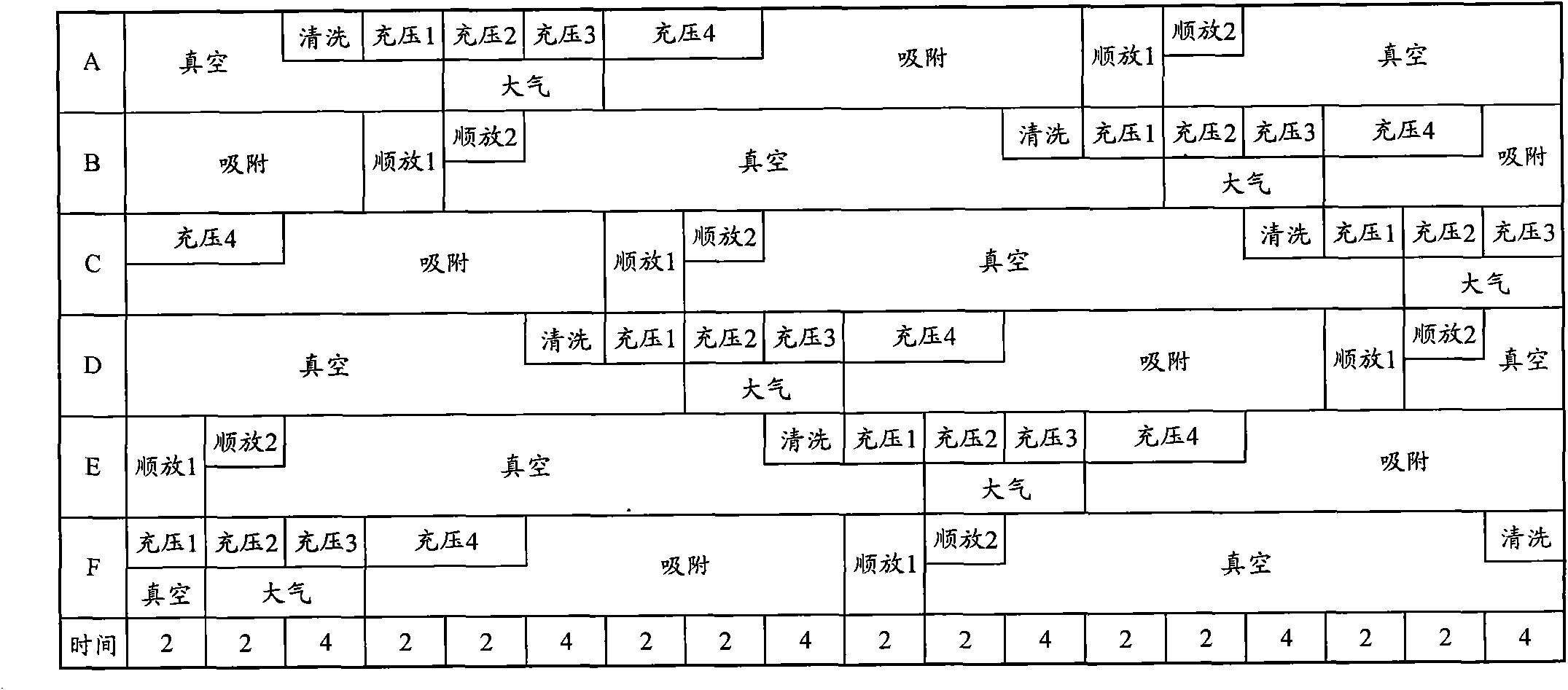

[0054] One of the core ideas of the embodiment of the present invention is to propose a six-tower vacuum pressure swing adsorption system that expands the scale of oxygen production on the basis of reducing system energy consumption and saving costs. This system uses six adsorbers to expand the production capacity. Oxygen scale, and use two sets of independent blowers to continuously deliver compressed air to the adsorber. When the pressure of the adsorber is lower than the atmospheric pressure, the adsorber will also suck raw material air from the atmosphere, thereby reducing the exhaust volume of the blower, which is reasonable Shorten the adsorption time; this system also uses three sets of vacuum pumps to vacuumize the three ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com