Pipe-communicated double-partition-wall heat transfer heat exchanger and manufacturing process thereof

A technology of heat exchangers and connecting pipes, applied in the field of heat transfer water heaters connected by stainless steel pipes to double partition walls, to achieve the effects of high cost of copper materials, accelerated heat conduction rate, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

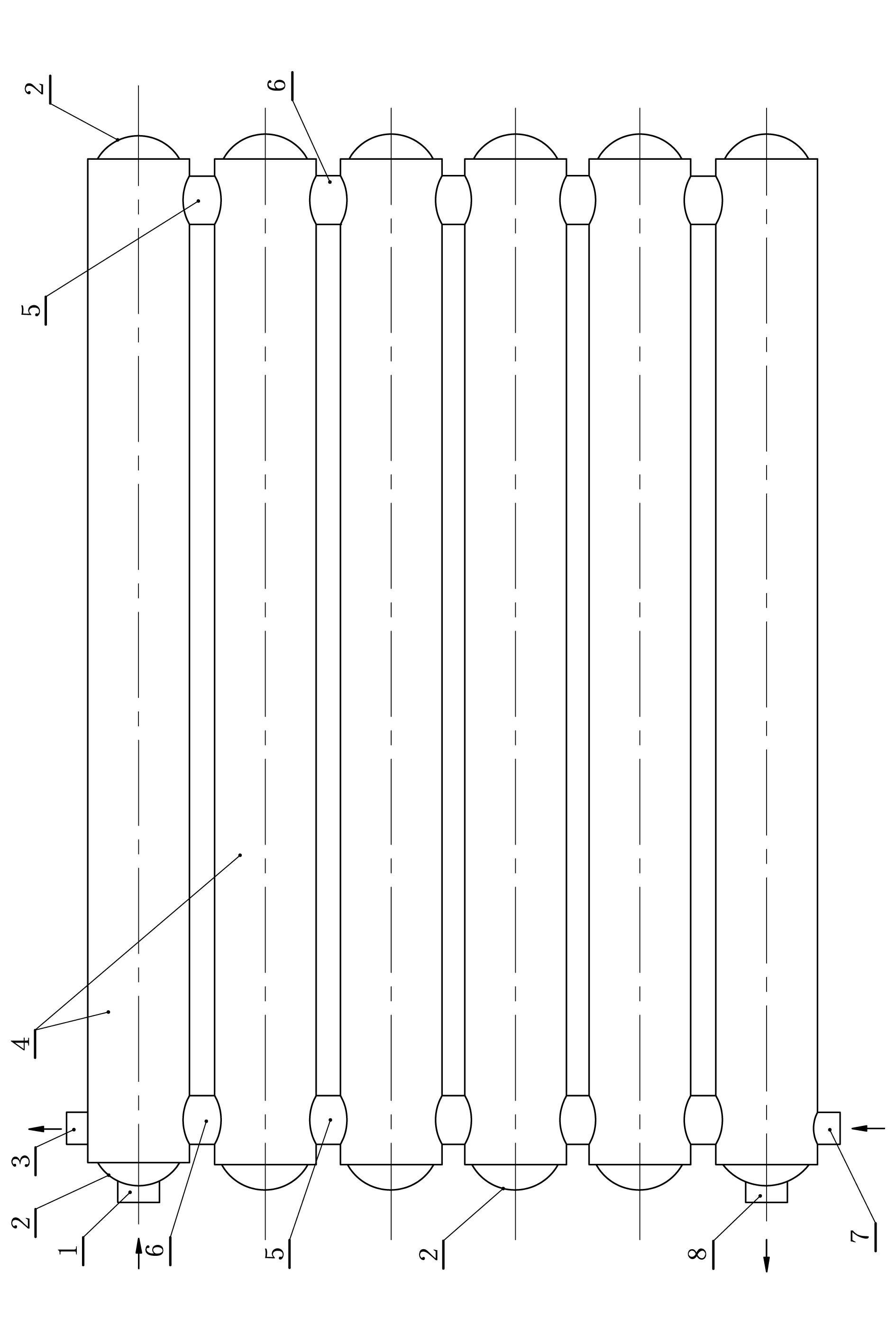

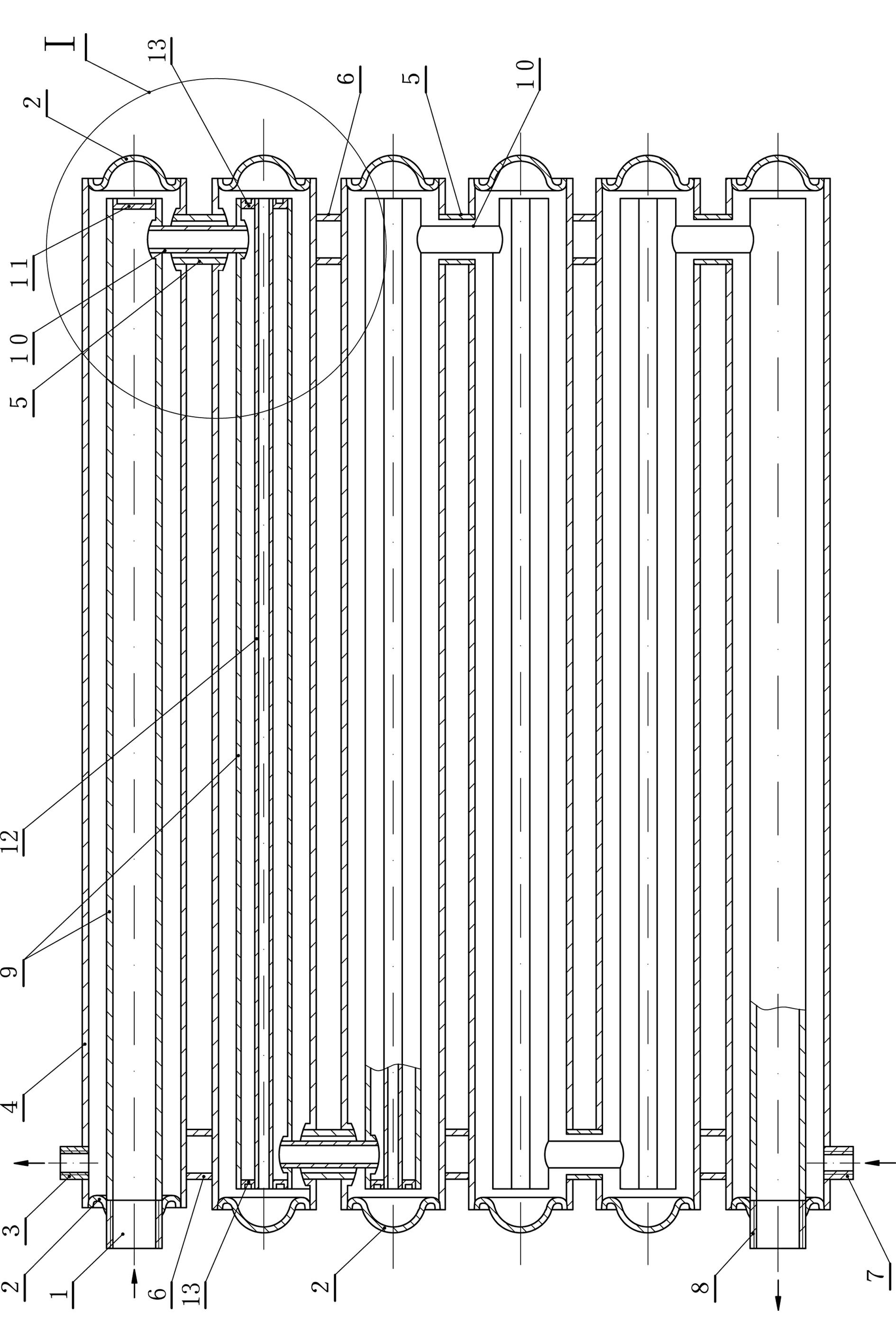

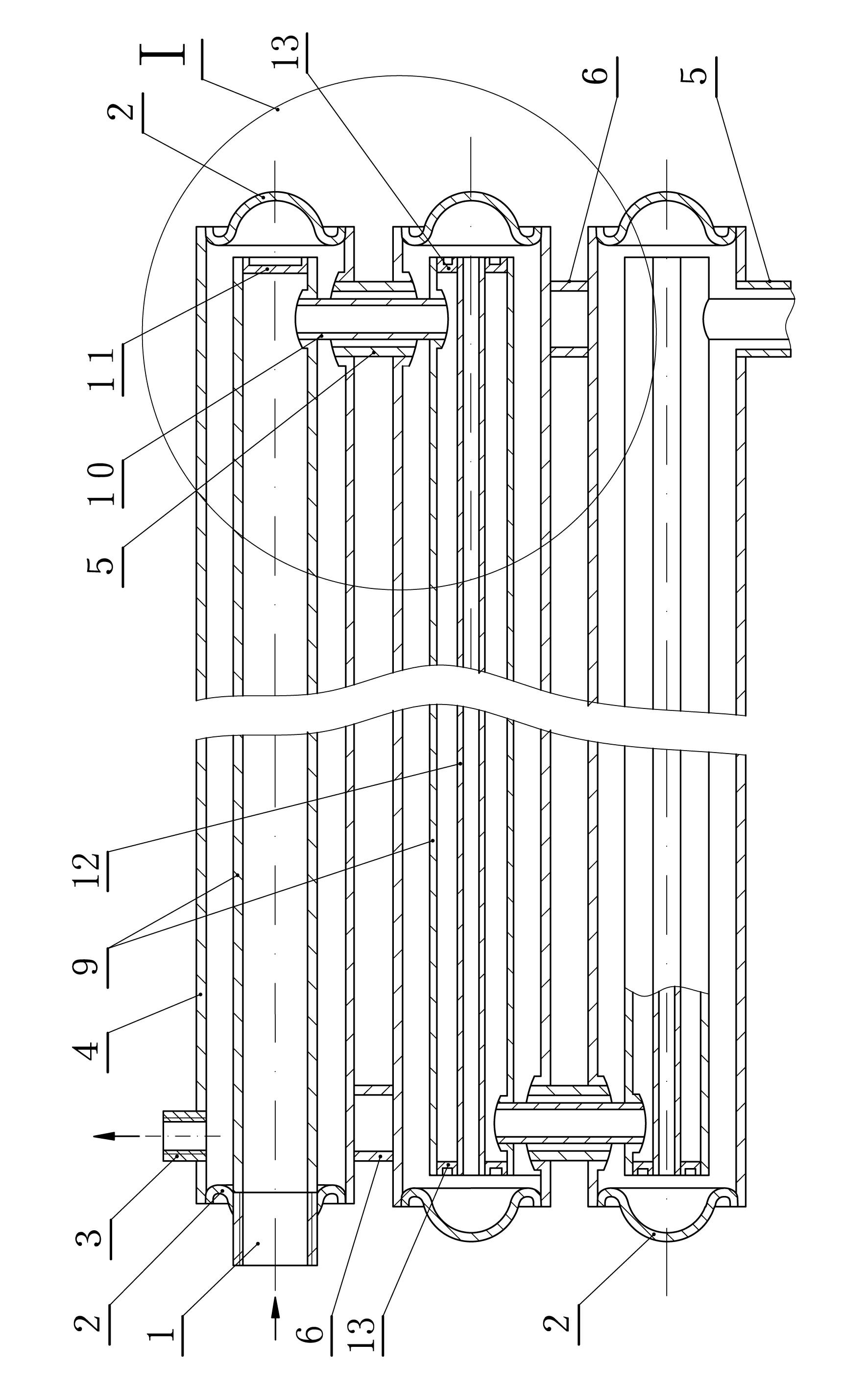

[0030] The tube of the present invention communicates with double-wall heat transfer heat exchanger such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes: two or more tap water heat-absorbing outer pipes 4. The heat pipe 9 and the tap water heat-absorbing outer pipe 4 are connected through the tap water connecting pipe 5, and the heat supply pipe 9 is connected through the heat supply pipe connecting pipe 10; the heating inlet 1 and the heating outlet 8 are connected with the inlet ends of the heating pipe 9 It is fixedly connected with the outlet, and the tap water inlet 7 and the tap water outlet 3 are fixedly connected with the inlet end and the outlet end of the tap water heat-absorbing outer pipe 4 respectively; it is characterized in that: part or all of the heat supply pipes 9 are provided with tap water hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com