Heater multi-pipe heat conducting type shell-tube water storage bearing heat interchanger and manufacturing technology thereof

A heat-conducting shell and heat-exchanger technology, which can be applied to heat-exchanger types, heat-exchanger shells, and indirect heat-exchangers, etc., can solve the problems of low effective utilization of heat, water leakage in the welds of connecting pipes, and small heat transfer area. , to achieve the effect of reducing oxidation corrosion, reducing stress deformation, and accelerating thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

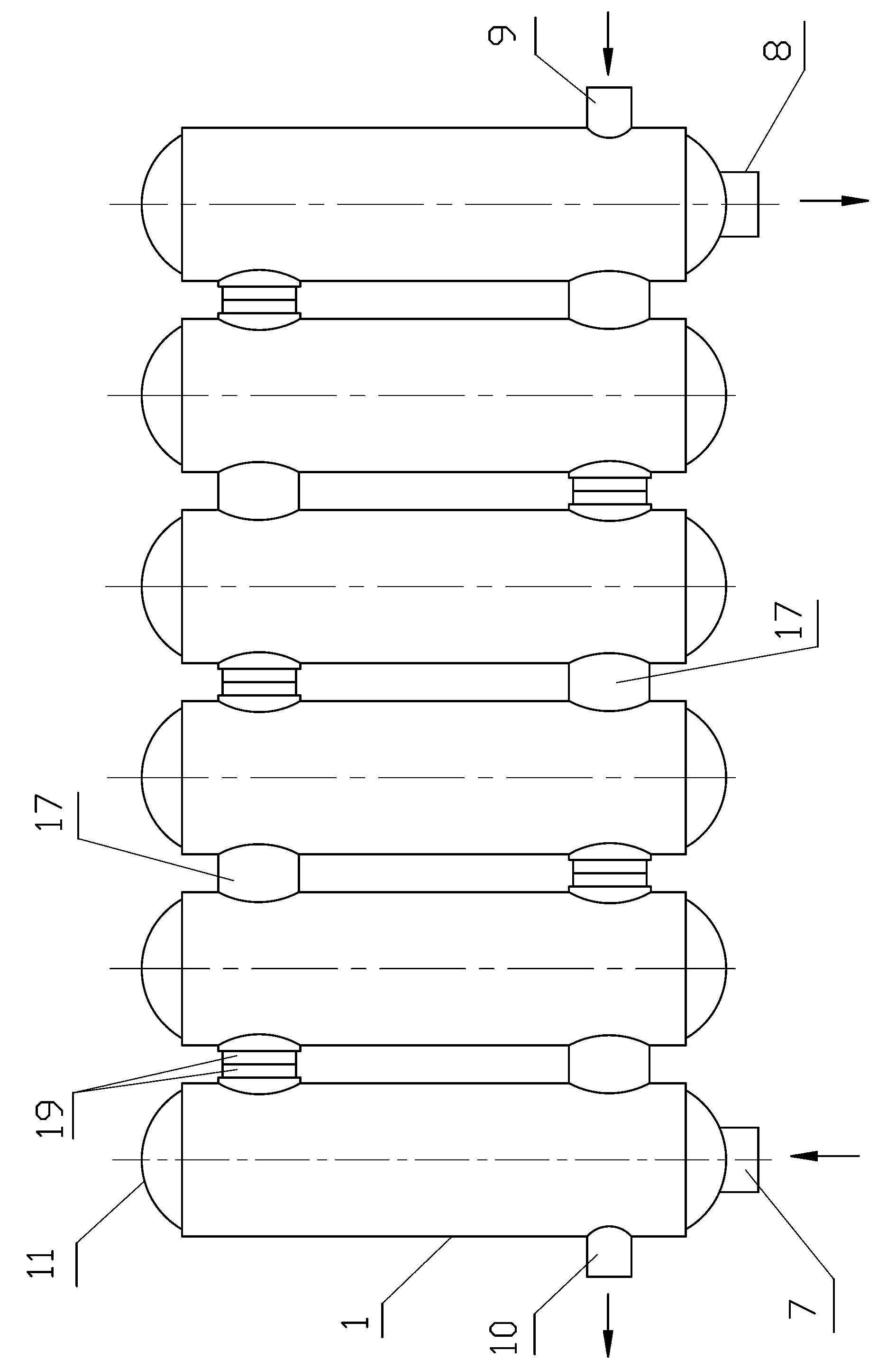

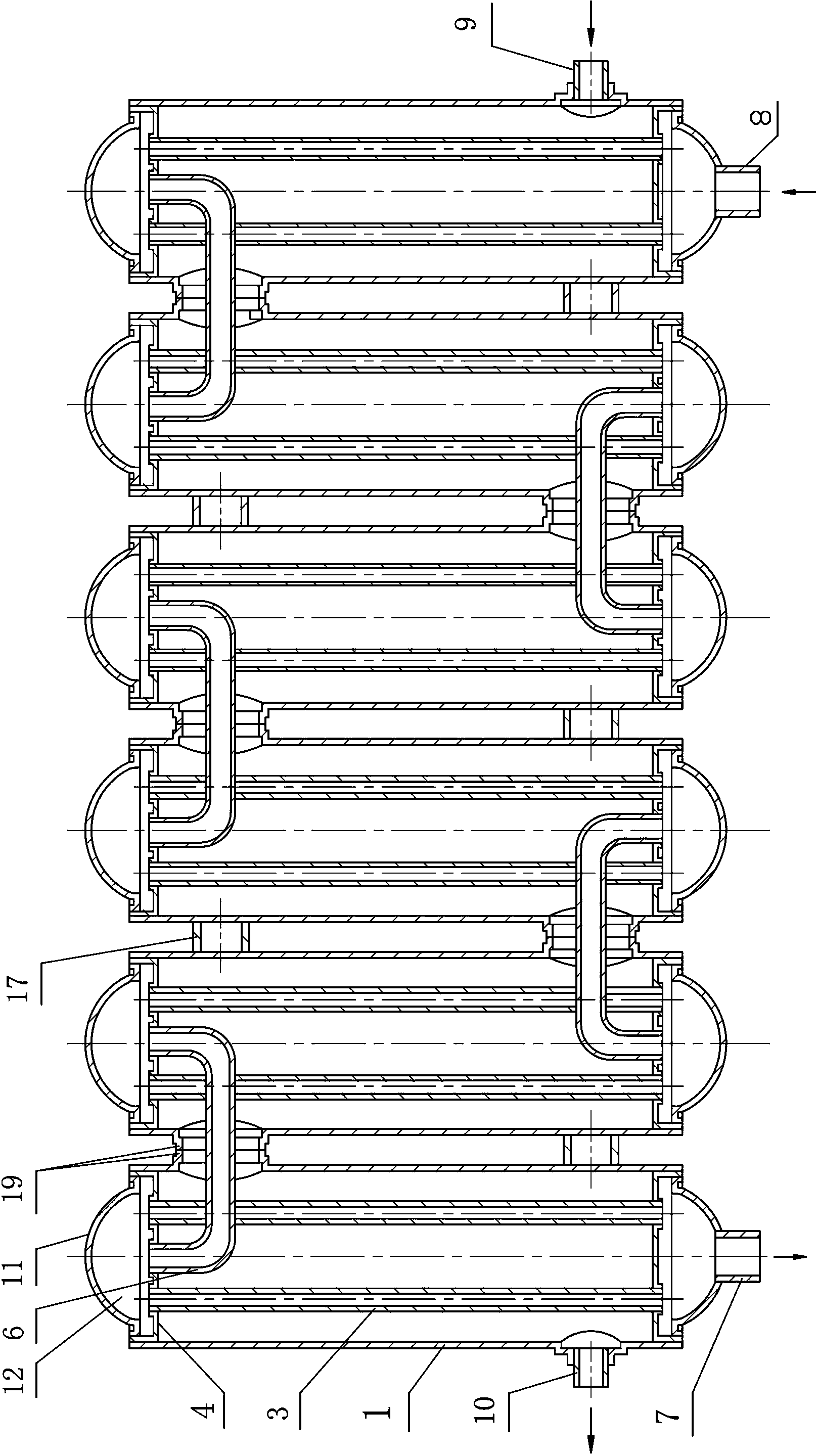

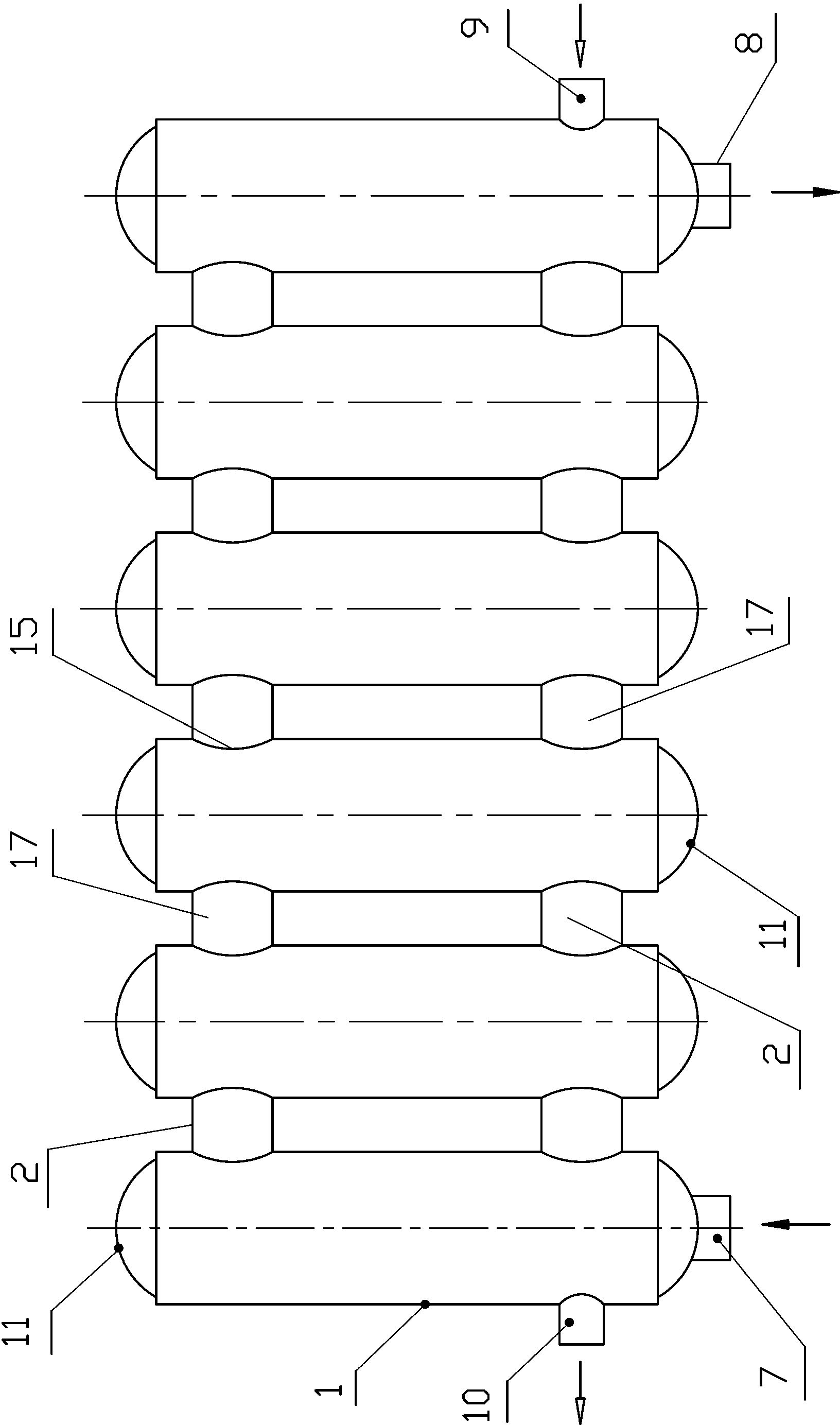

[0043] The present invention is a heating multi-tube heat conduction shell tube water storage pressurized heat exchanger such as Figure 1 to Figure 19 shown.

[0044] 1, the present invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, it includes a plurality of cold water round pipes 1, cold water inlet pipe joints 9 and cold water outlet pipe joints 10, heating air inlet pipe joints 7 and heating air outlet pipe joints 8, and the two ends of the cold water round pipes 1 are respectively welded with end caps. Plate 11, one end of the plurality of cold water round pipes 1 and one end of the side pipe and the adjacent cold water round pipe 1 have a cold water pipe connection port 15 on the arc surface pipe wall between the adjacent cold water round pipes 1. Cavity; cold water pipe connection port 15 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com