Distributing head of disk dewatering machine

A disc dewatering and distributing head technology, which is used in filtration separation, separation methods, membrane filters, etc., can solve the problems of large leakage, insufficient wear resistance, and reduced life of the whole machine, so as to increase the adsorption area and improve the adsorption effect. , the effect of improving the adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

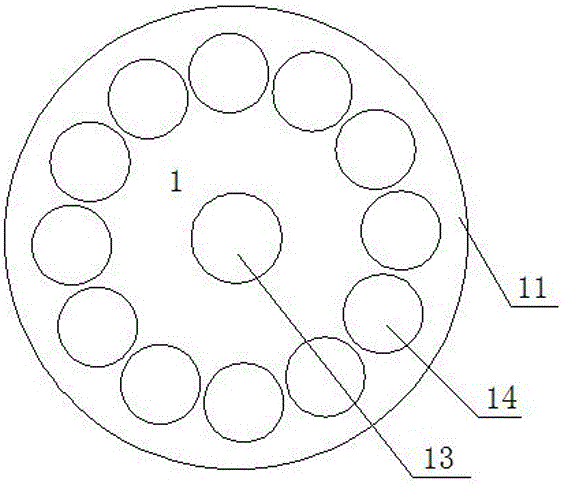

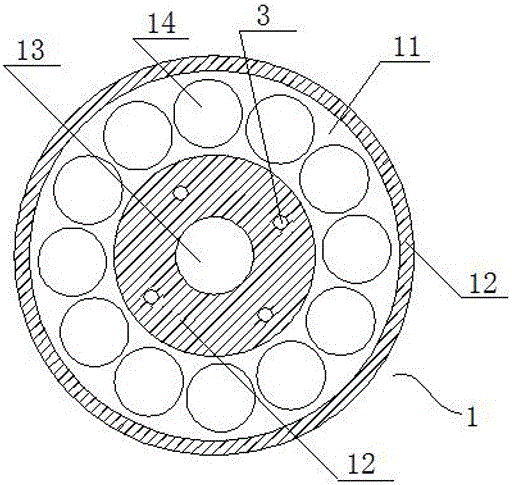

[0018] Such as image 3 , 4 As shown, a dispensing head of a disc dehydrator includes a rotating part 1 and a fixed part 2, and the opposite faces of the rotating part 1 and the fixing part 2 are pressed together by spring force; the rotating part 1 is provided with a rotating part contact table 11 And the rotating part sinking platform 12, the rotating part contacting platform 11 takes the center of the circle of the dehydrator shaft 13 as the center, and the distance from the center of the circle of the holes 14 uniformly distributed on the rotating parts to the center of the circle of the dehydrator shaft 13 is the base radius. The value obtained by subtracting the hole radius from the base radius and the hole radius of 1 / 6 to 1 / 8 is the inner radius r1, and the value obtained by adding the base radius to the hole radius and the hole radius of 1 / 6 to 1 / 8 is the outer radius r2, forming The ring-shaped platform of the rotating part; the rotating part sinking platform 12 is ...

Embodiment 2

[0021] On the basis of Embodiment 1, the rotating part 1 is provided with 4 to 6 fixed fixed parts evenly distributed with the center of the dehydrator shaft 13 on the sunken platform of the rotating part formed from the center of the dehydrator shaft 13 to the inner radius. Bolt holes 3 are used to connect the shaft of the dehydrator; 4 to 6 fixed bolt holes 3 evenly distributed with the center of the dehydrator shaft 13 as the center of the circle are also arranged on the corresponding fixed part sinking platform of the fixed part 2, which are used for Attach the dehydrator housing.

[0022] The rotating part and the fixed part are made of hard alloy with anti-corrosion properties, which are integrally casted and then sintered at high temperature. The surface is finely ground to a smoothness of 0.003-0.006 μm, and the hardness reaches 94.5H.

[0023] 4-6 positioning holes are used respectively, and they are fixed on the main shaft and the body frame with bolts, which is conv...

Embodiment 3

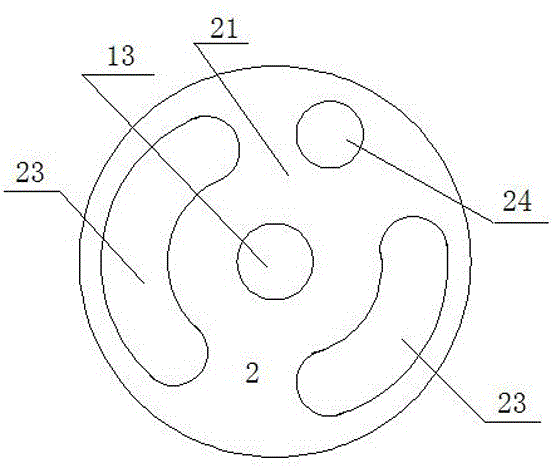

[0025]The fixed part 2 is also provided with a material loose pipe 25, which is located next to the flushing pipe 24, and the center of the logistics loose pipe 25 and the flushing pipe 24 are on the same circumference. The distribution head can prevent the fluid medium from leaking between the slurry suction tank and the flushing pipe, so that the dehydrator can normally complete the five working processes of slurry suction, filtration, drying, unloading, and backwashing. But at present, the dehydrator also has five processes of slurry suction, filtration, drying, loosening, and unloading. The function of the distribution head is the same, but the flushing pipe becomes a loose pipe, or a loose pipe is added, and the relative position is slightly changed. The changing method is fixed. The water inlet flushing pipe on the component is directly changed to the air inlet drying material loose pipe; or it can also be used as the water inlet flushing pipe unchanged, and a round hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com