Biomass hydrogen production composite difunctional particle and preparation method and application thereof

A dual-function, biomass technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, hydrogen, etc., can solve the problem of high cost, achieve large adsorption capacity, long adsorption time, and production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

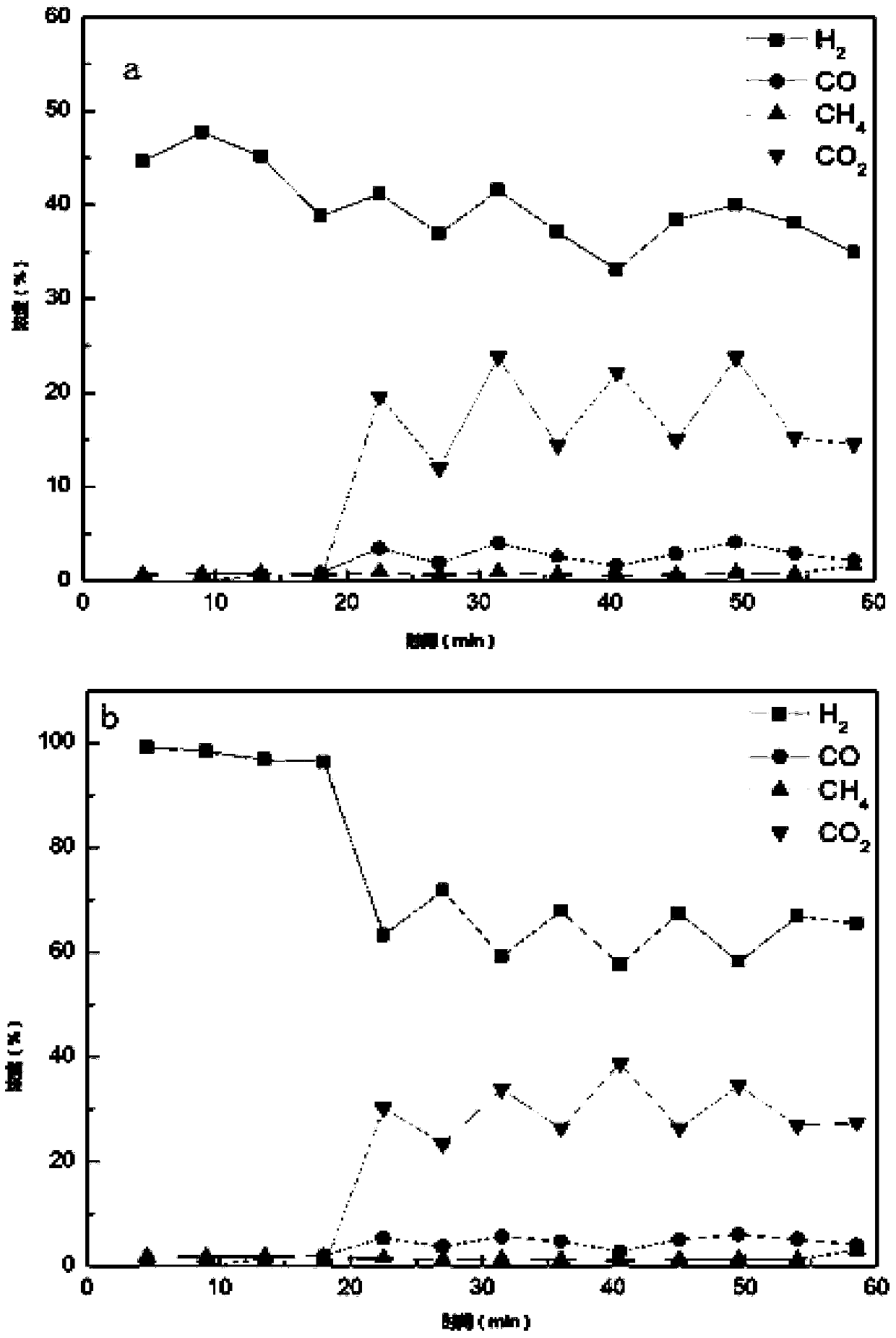

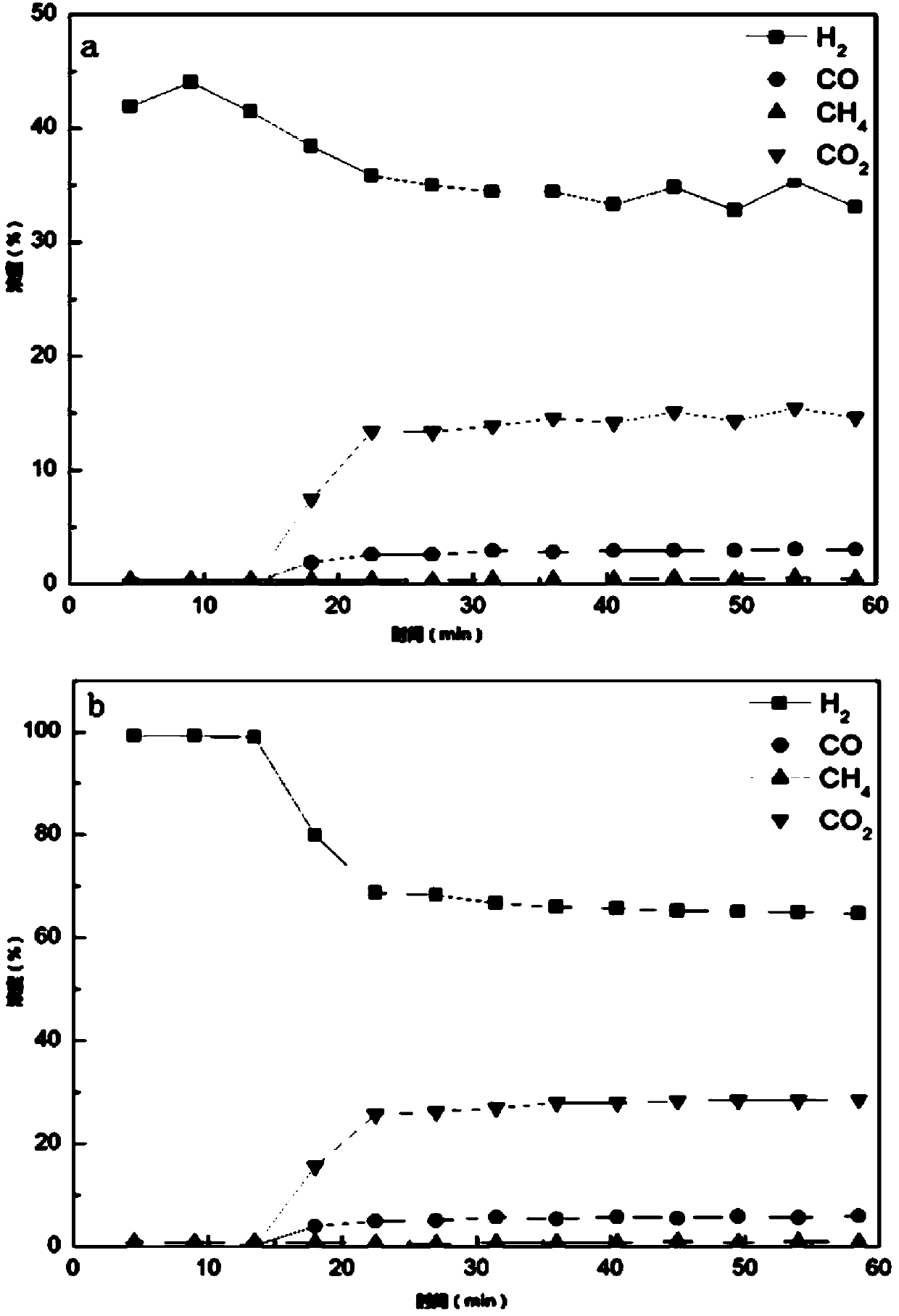

[0020] Weigh 9.42g of calcium acetate, 3.46g of nickel nitrate, 0.45g of ferric nitrate and 5.62g of citric acid, add distilled water and stir to dissolve completely, keep stirring and drying the solution at 100°C, and then calcinate at 900°C for 3 hours and then crush to obtain A composite bifunctional particle for hydrogen production from biomass with 24 to 50 meshes. In the hydrogen production reaction of adsorption-enhanced glycerol steam reforming, 1.24g of this bifunctional particle was used as a catalyst, and the space velocity of glycerol was 22h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 700°C, and the reaction temperature is 600°C, such as figure 1 .

[0021] Such as figure 1 As shown, before 18 minutes, the hydrogen concentration reached 98%. After 18 minutes, the adsorption of the adsorbent gradually reached saturation, the relative content of hydrogen gradually decreased, and finally stabilized at abo...

Embodiment 2

[0025] Weigh 9.42g of calcium acetate, 3.46g of nickel nitrate, 0.45g of ferric nitrate and 5.62g of citric acid, add distilled water and stir to dissolve them completely, keep stirring the solution at 80°C and dry it, then calcinate at 700°C for 2 hours and then crush it to obtain A composite bifunctional particle for hydrogen production from biomass with 24 to 50 meshes. In the adsorption-enhanced acetic acid steam reforming hydrogen production reaction, 1.24g of this bifunctional particle was used as a catalyst, and the space velocity of acetic acid was 11h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.1MPa, the pre-reduction temperature is 600°C, and the reaction temperature is 500°C. According to experiments, the composite bifunctional particles prepared under this condition act on the hydrogen production reaction of acetic acid steam reforming, and the hydrogen concentration obtained is slightly lower than that in Example 1.

Embodiment 3

[0027] Weigh 9.42g of calcium acetate, 3.46g of nickel nitrate, 0.45g of ferric nitrate and 5.62g of citric acid, add distilled water and stir to dissolve them completely, keep stirring the solution at 120°C and dry it, then calcinate at 1100°C for 5 hours and then break it to obtain A composite bifunctional particle for hydrogen production from biomass with 24 to 50 meshes. In the adsorption-enhanced acetic acid steam reforming hydrogen production reaction, 1.24g of this bifunctional particle is used as a catalyst, and the space velocity of acetic acid is 55h -1 , the water-to-carbon ratio is 3:1, the reaction pressure is 0.3MPa, the pre-reduction temperature is 800°C, and the reaction temperature is 600°C. According to experiments, the composite bifunctional particles prepared under this condition acted on the hydrogen production reaction by steam reforming of acetic acid, and the resulting hydrogen concentration was slightly higher than that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com