Floating trend type oil surface adsorption device

An adsorption device and trending technology, which is applied in the field of floating trending oil surface adsorption devices, can solve the problems that the adsorbent is not easy to collect in a centralized manner, secondary pollution of sewage, low adsorption efficiency, etc., and achieve the effect of prolonging the use time of oil adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

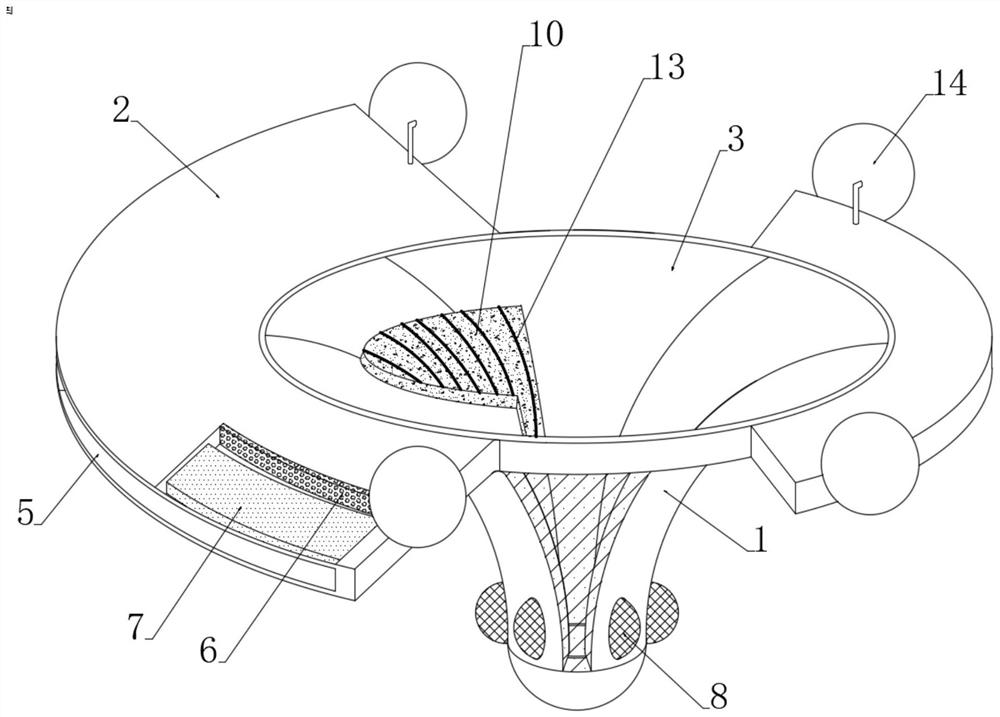

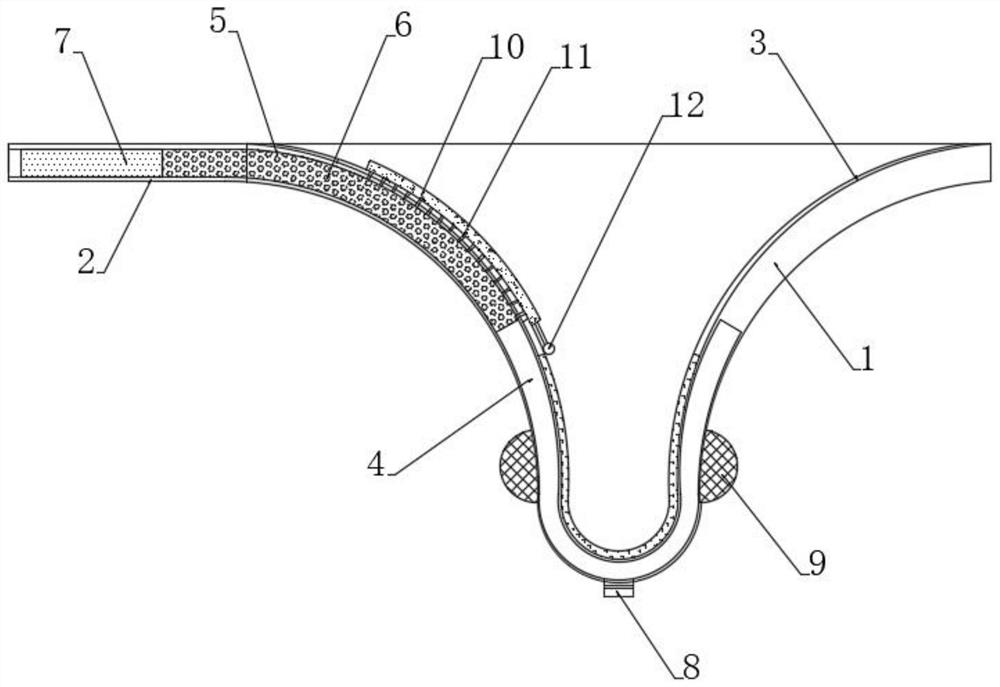

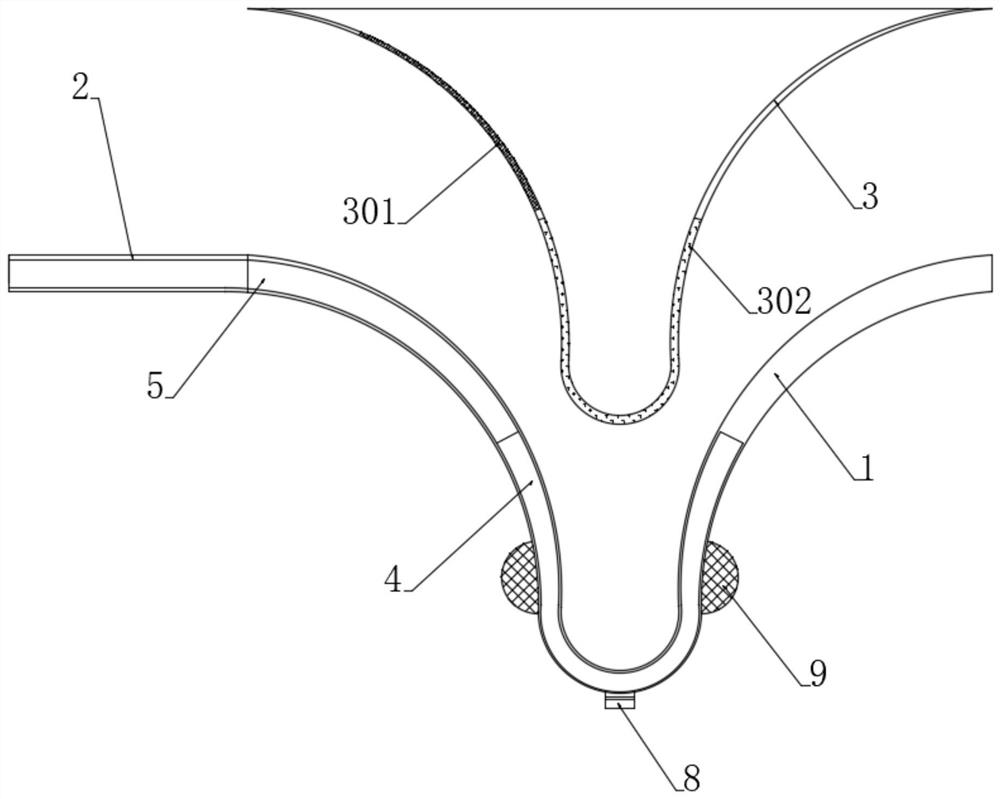

[0035] see Figure 1-2 , a floating tendency type oil surface adsorption device, comprising a horn-shaped adsorption table 1 and an arc-shaped adsorption floating plate 2 fixedly connected to the top side of the horn-shaped adsorption table 1, the bottom end of the horn-shaped adsorption table 1 is fixedly connected with a plurality of Evenly distributed draft hollow heavy bodies 9, the trumpet-shaped adsorption table 1 is provided with a plurality of floating balls 14, the arrangement of multiple draft hollow heavy bodies 9 is conducive to the bottom end of the trumpet-shaped adsorption table 1 sinking below the water surface, The inner bottom of the trumpet-shaped adsorption table 1 is provided with a drainage chamber 4, and the interior of the arc-shaped adsorption floating plate 2 and the connection between the arc-shaped adsorption floating plate 2 and the trumpet-shaped adsorption table 1 are provided with an adsorption chamber 5, and the bottom of the adsorption chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com