Automatic oil coating device of automobile motor rotor

A technology for motor rotors and oiling devices, which is applied in the direction of electromechanical devices, devices for coating liquid on the surface, electric components, etc., can solve the problems of low efficiency, achieve the effects of increasing speed, good dust removal, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

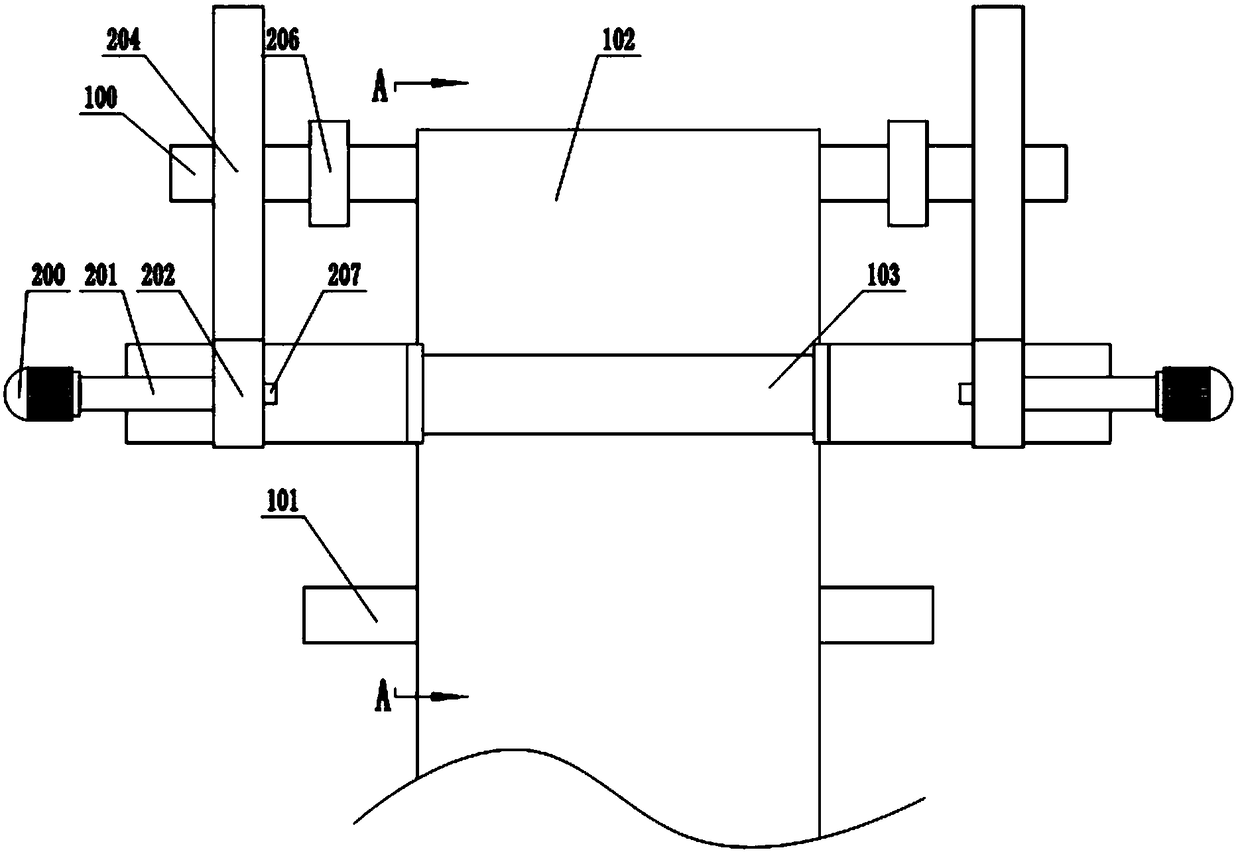

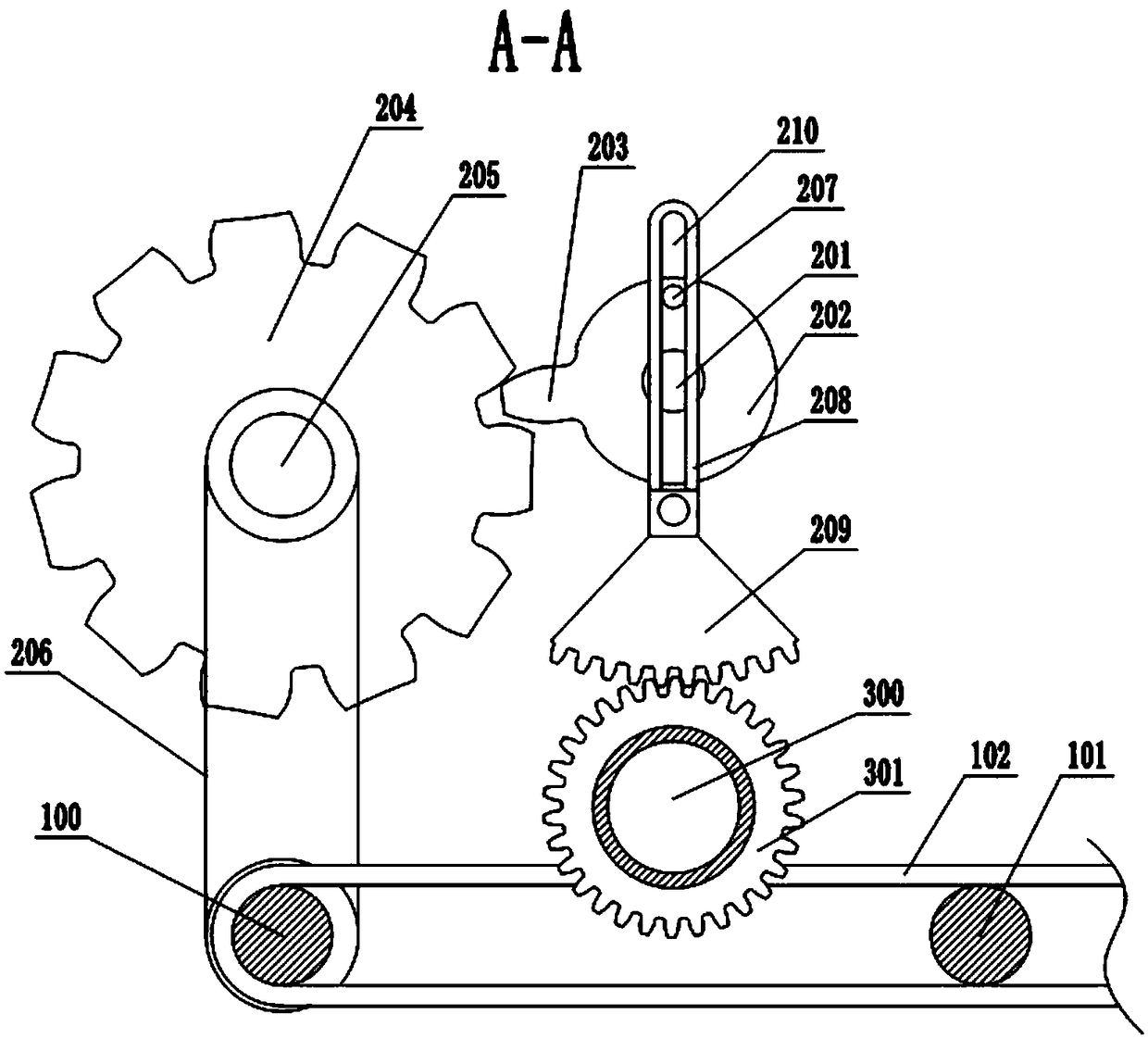

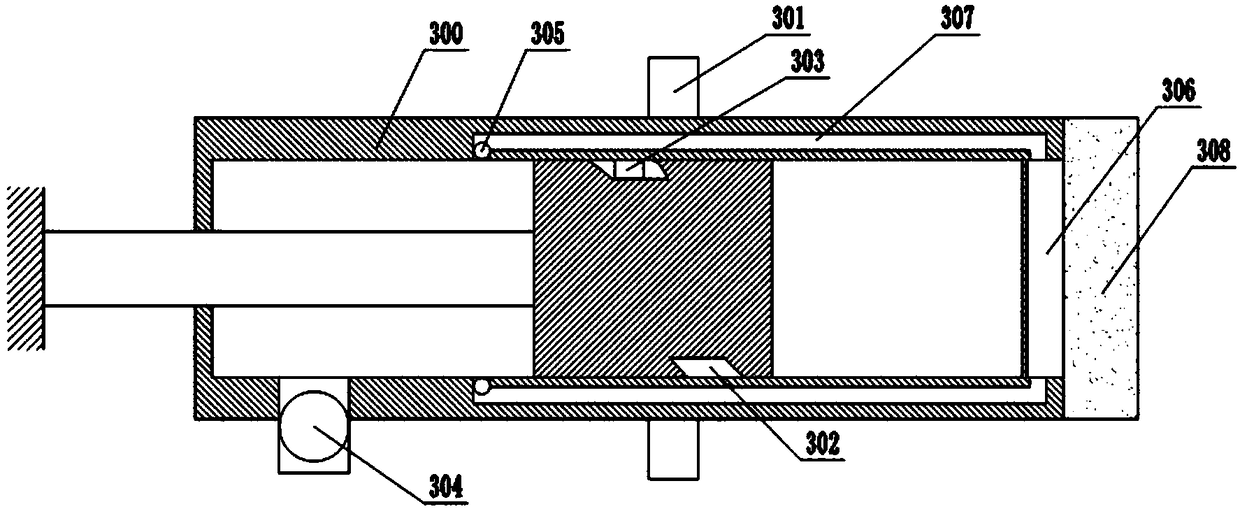

[0029] The reference signs in the drawings of the description include: tensioning shaft 100, support shaft 101, conveyor belt 102, positioning slot 103, motor 200, rotating shaft 201, driving wheel 202, convex teeth 203, first gear 204, gear shaft 205, belt Transmission mechanism 206, first bump 207, swing arm 208, sector gear 209, first groove 210, cylinder 300, second gear 301, second groove 302, second bump 303, oil inlet valve 304, outlet Oil valve 305, oil tank 306, oil pipe 307, sponge 308, air intake check valve 309, air outlet check valve 310, air spray head 311.

[0030] Such as figure 1 and figure 2 Shown is the embodiment of the present invention, announced the automatic oiling device of automobile motor rotor, and this device is made up of three parts, comprises the transfer device that transports the motor rotor to be oiled, drives the drive device that transfers devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com