Wheel rim fatigue analysis method

A fatigue analysis and steel ring technology, applied in the field of auto parts, can solve the problems of long development cycle and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

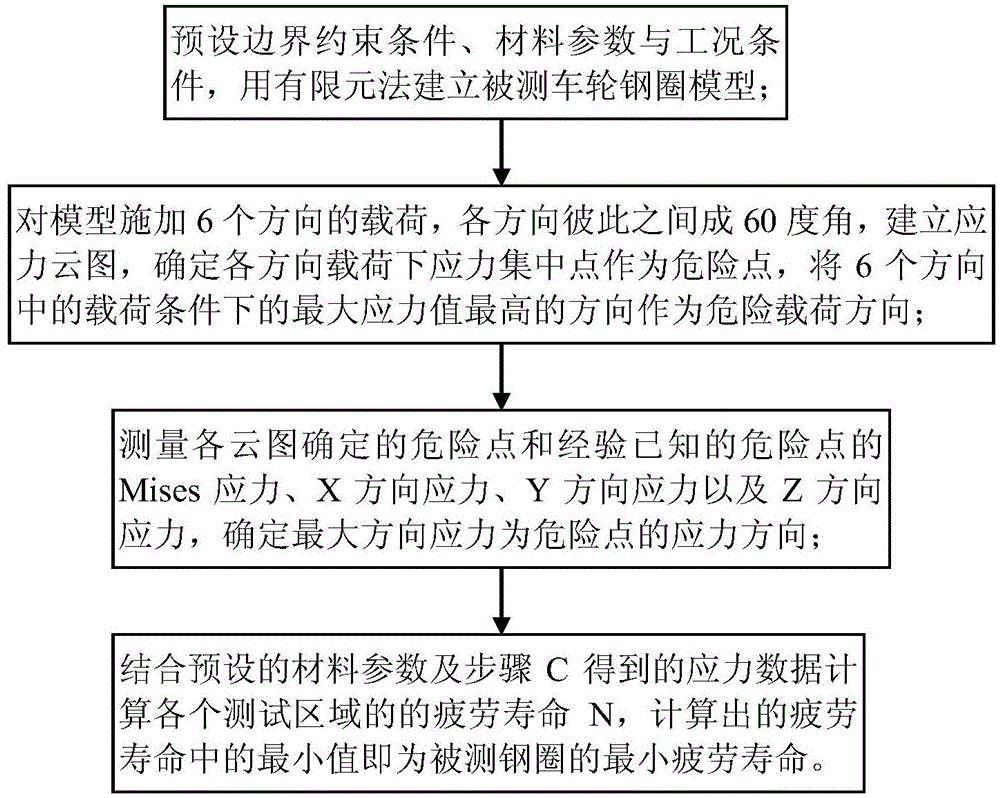

[0022] The wheel steel rim fatigue analysis method of the present embodiment comprises the following steps:

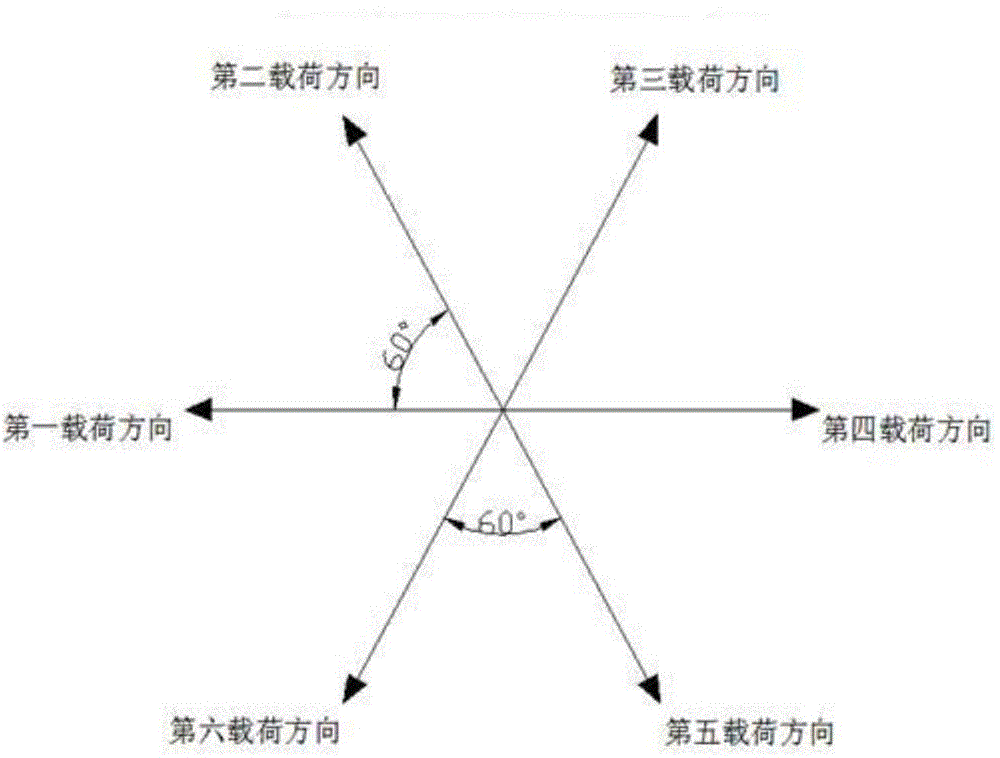

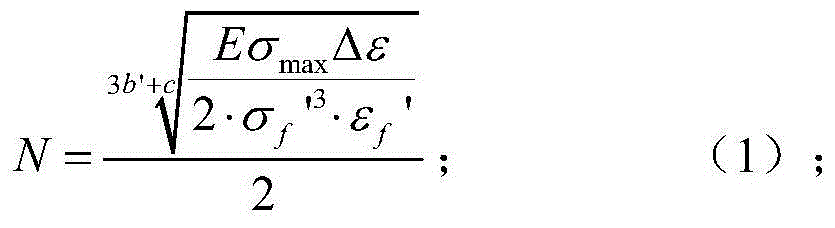

[0023] This embodiment uses the finite element method to establish the model of the tested wheel rim, the preset working condition is that the bending moment is 20Kn. The loads in 6 directions, each direction forms an angle of 60 degrees with each other, establishes a stress cloud map, and determines the stress concentration point under the load in each direction as a dangerous point. The dangerous points obtained on the stress cloud map of this embodiment are the small holes of the ventilation holes and the ventilation holes. On both sides of the hole notch direction, the dangerous points known from experience include: the bolt hole of the steel ring, the weld between the steel ring and the rim, and the large hole connecting the spoke and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com