Focused ultrasonic vibration working solution electrochemical machining device and method

An electrochemical machining and ultrasonic vibration technology, applied in electrochemical machining equipment, electric machining equipment, accessories, etc., can solve the problem that the fluidity of the electrolyte cannot be fully improved, the discharge of electrolytic products, the vibration frequency of the vibration drive unit is not high enough, and the Problems such as ultrasonic cavitation effect are generated, and the effect of increasing circulation and update speed, reducing gap and avoiding loss is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

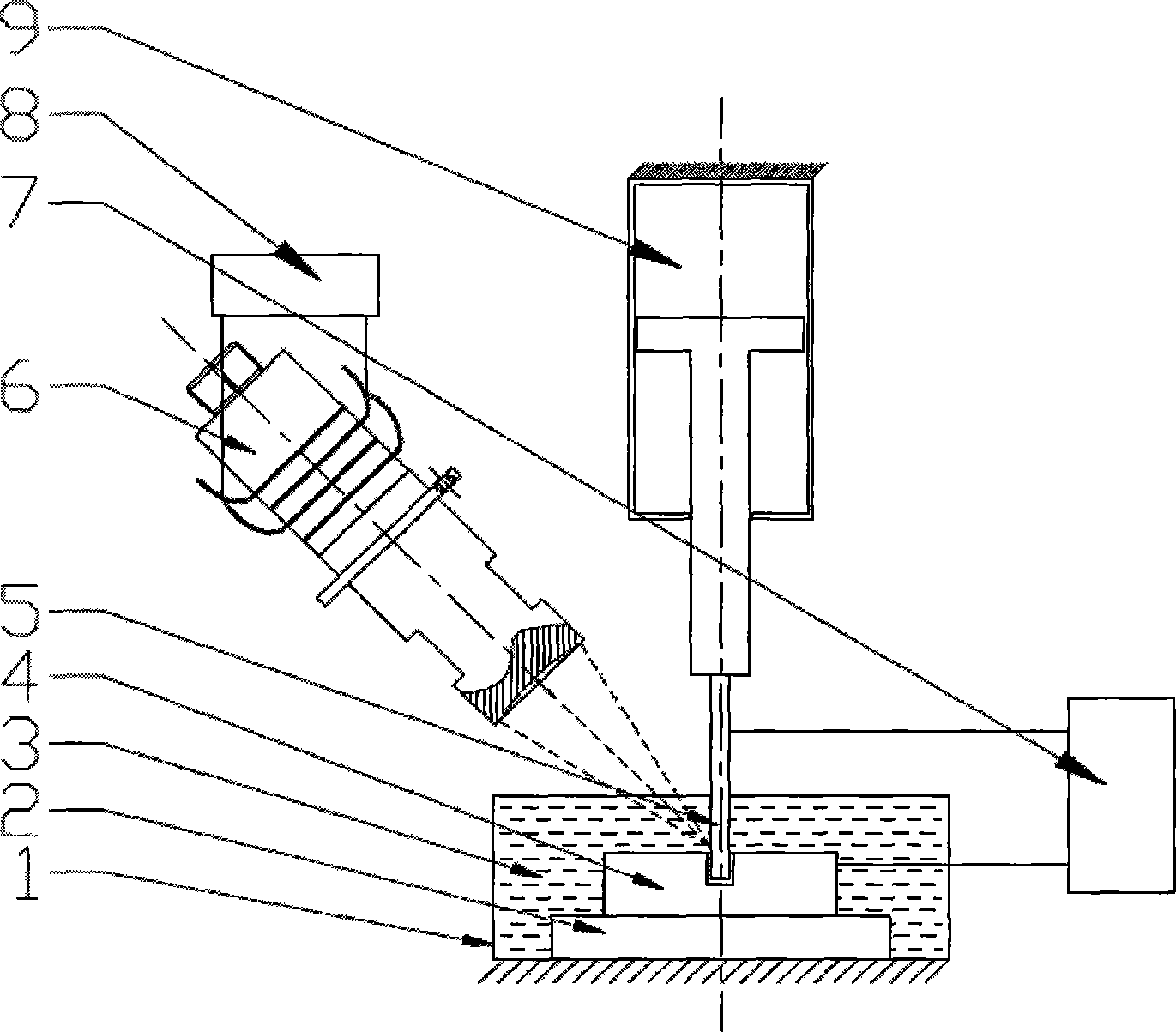

[0026] An embodiment of the focused ultrasonic vibration working liquid electrochemical processing device of the present invention, as attached figure 1 As shown, in this embodiment, a focused ultrasonic vibration working liquid electrochemical processing device includes an electrochemical processing device and an ultrasonic vibration device; the electrochemical processing device includes an electrolyte tank 1, a workpiece fixture 2, and a power supply 7. Electrolyte 3 is contained in the electrolyte tank 1, the workpiece fixture 2 is arranged in the electrolyte tank 1, and a workpiece 4 is fixed above the workpiece fixture 2, and the workpiece 4 is submerged in the electrolyte 3 Among them, a tool 5 perpendicular to the workpiece 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com