Electrolyte precise control system with real-time adjustable parameters and working method thereof

A technology of precision control and electrolyte, which is applied in the direction of processing working medium supply, etc., can solve the problem of inability to guarantee constant electrolyte parameter processing, variable flow and constant flow speed processing, precise control of electrolyte viscosity and temperature, and easy blockage of the nozzle head of the injection device , can not control the electrolyte and other problems, to achieve the effect of improving machining accuracy, improving precision and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, concrete implementation process of the present invention is described in detail as follows

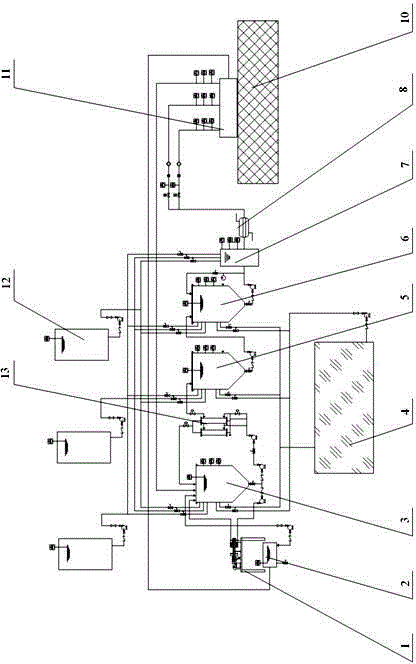

[0031] Implementation of the present invention "electrolyte precision control system with adjustable parameters in real time and its working method", such as figure 1 As shown, the main devices of the system include: ceramic membrane filter 13, turbid liquid tank 3, buffer tank 5, clear liquid tank 6, sampling adjustment tank 7, constant temperature water bath device 8, heat exchange equipment 4, multiple ion concentration adjustment tanks Group 12, solid-liquid separation device 1, control cabinet, multiple sensors and automatic regulating valve, etc.

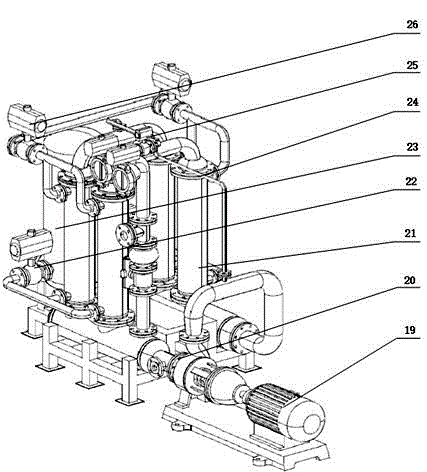

[0032] The main components of the electrolyte fine filtration part include turbid liquid tank 3, ceramic membrane filter 13, buffer tank 5, solid-liquid separation equipment 1, and multiple automatic regulating valves and sensors. The electrolyte fine filtration part can stably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com