Electrode and machining device and method for electrolytic cutting rapid forming of turbine disc mortise

A technology for cutting electrodes and processing methods, applied in electric processing equipment, electrochemical processing equipment, processing electrodes, etc., can solve the problems of low efficiency, high cost, unstable quality, etc., achieve high efficiency, low cost, and solve processing accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

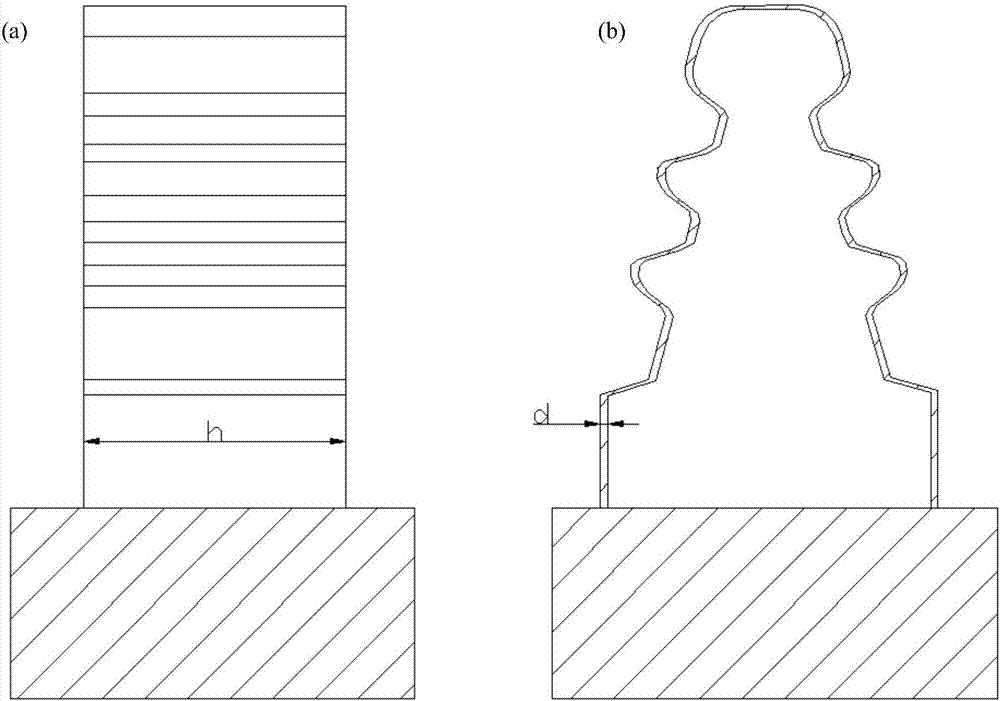

[0055] An electrode for rapid prototyping by electrolytic cutting of turbine disk tongue and groove, its side view is shown in figure 1 (a), its front view is shown in figure 1 (b), wherein, in the figure, h is the height of the electrode of the rapid prototyping of the electrolytic cutting of the turbine disc tenon and groove, and d is the cross-sectional area of the electrode of the rapid prototyping of the electrolytic cutting of the tenon and groove of the turbine disc;

[0056] The electrode for rapid prototyping of the turbine disk tenon and groove electrolytic cutting is a cutting electrode, which is used as a tool cathode on an electrolysis machine tool to perform rapid cutting and forming processing on the turbine disk tenon and groove, and its material is a copper-tungsten alloy material;

[0057] The cutting electrode is of a thin-walled structure, and its profile is designed into different mortise and groove shapes according to the mortise and groove of different...

Embodiment 2

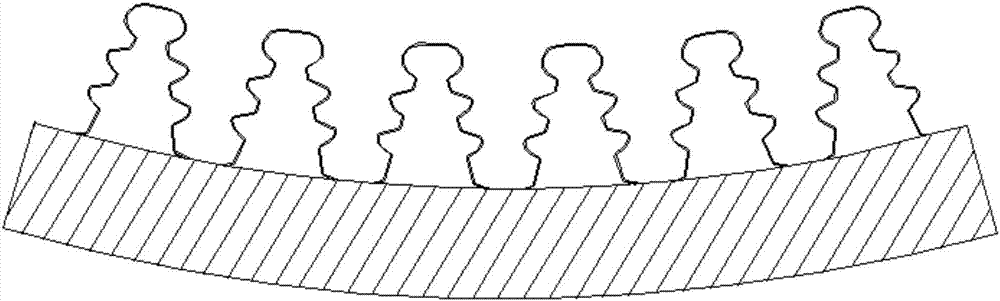

[0091] An electrode for rapid prototyping by electrolytic cutting of turbine disk tenon and groove, its schematic diagram is shown in figure 2 , the electrode for rapid prototyping of the turbine disk tenon and groove electrolytic cutting is a cutting electrode, which is used as a tool cathode on an electrolysis machine tool to perform rapid cutting and forming processing on the turbine disk tenon and groove, and its material is stainless steel;

[0092] The cutting electrode is of a thin-walled structure, and its profile is designed into different mortise and groove shapes according to the mortise and groove of different turbine disk parts through clearance calculation, so as to meet its no-residue forming processing requirements;

[0093] The cross-sectional area d of the cutting electrode should ensure that the electrolyte can smoothly flow into the processing area after the cutting electrode enters the workpiece anode;

[0094] The height h of the cutting electrode is the...

Embodiment 3

[0116] An electrode for rapid prototyping by electrolytic cutting of a turbine disk tenon and groove is the same as that in Embodiment 2, except that the cutting electrode is multi-station. In this embodiment, the number of multi-stations is 11. 11 single-position electrodes as a whole structure.

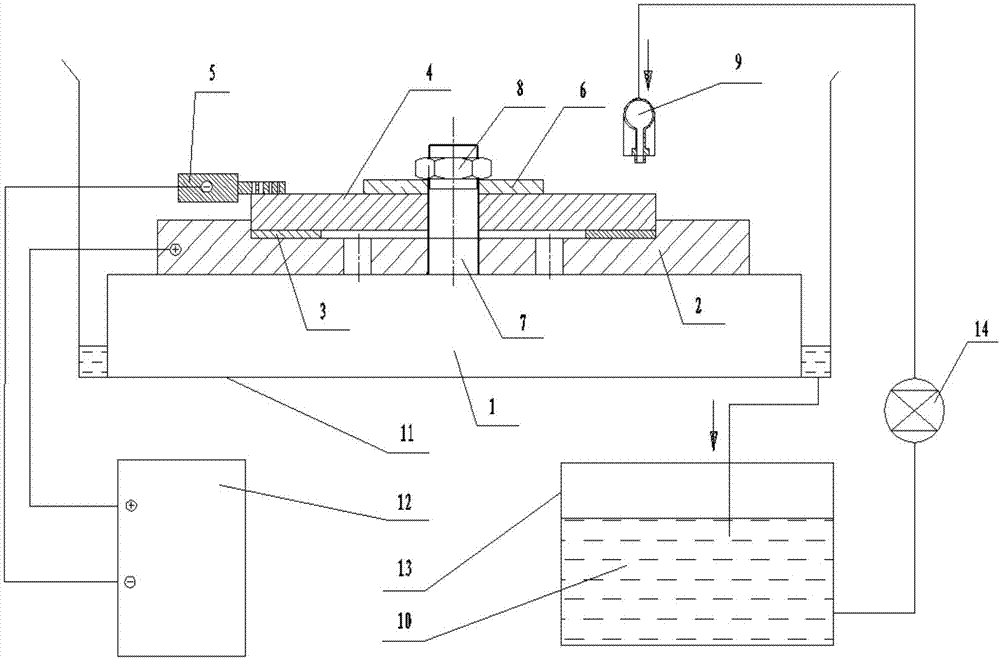

[0117] A processing device for rapid prototyping by electrolytic cutting of a turbine disk tenon and groove, which is the same as that in Embodiment 2, except that the cutting electrode used is the electrode of this embodiment.

[0118] A processing method for rapid prototyping of turbine disk tenon and groove electrolytic cutting, the same as embodiment 2, the difference is that this embodiment adopts the processing device of this embodiment, and in the processing process, it is determined according to the turbine disk parts to be processed and the test The range of process parameters is:

[0119] Processing voltage U: 20V; processing current I: 50A; electrolyte composition: NaNO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com