Iterative Method of Cathode for Precision Electrolytic Forming of Dual-Journal Blades Based on Deformation Control

A technology of deformation control and blade, applied in the direction of design optimization/simulation, special data processing application, etc., can solve problems such as no allowance machining, blade deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

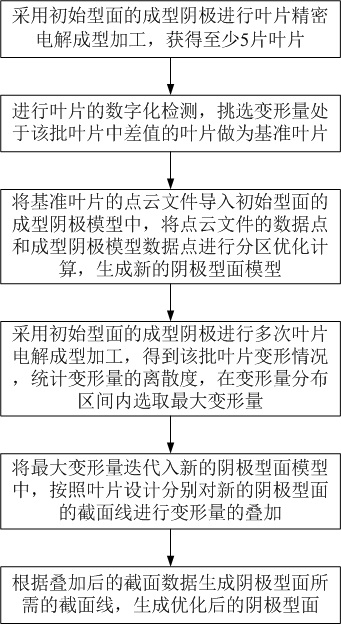

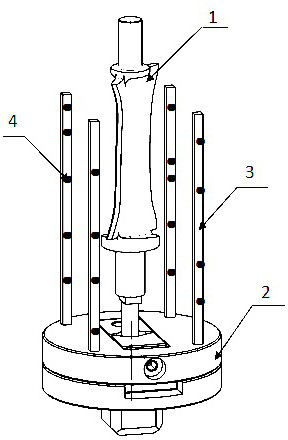

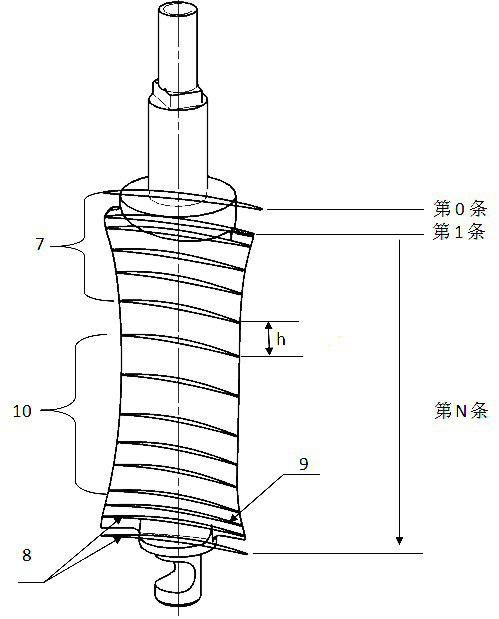

[0041] The iterative method for the cathode of double-journal blade precision electrolytic forming based on deformation control of the present invention first needs to carry out the detection data after the process verification based on the initial surface of the forming cathode, and then iterates the deformation amount explored in the iterative process, and finally Obtain the cathode profile after iteration. The molded cathode profile is a pair of working cathodes with three-dimensional curved surfaces.

[0042] The three-dimensional curved surface working cathode is a tool for electrolytic forming of blades. The initial profile of the working cathode can be designed according to the different shapes of the blade parts, according to the COS rule, and the initial profile of different shapes is calculated through gap calculation to ensure the initial processing of the blade profile. molding precision. After multiple experiments and optimization, the full-surface blue-ray three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com